Method for evaluating cut tobacco mixing uniformity

A technology of mixing uniformity and evaluation method, which is applied in the direction of removing certain components and weighing, etc., can solve the problems of inability to judge the uniform distribution of shredded tobacco and the inability to judge shredded tobacco, and achieve the effect of reliable technical parameters and evaluation data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

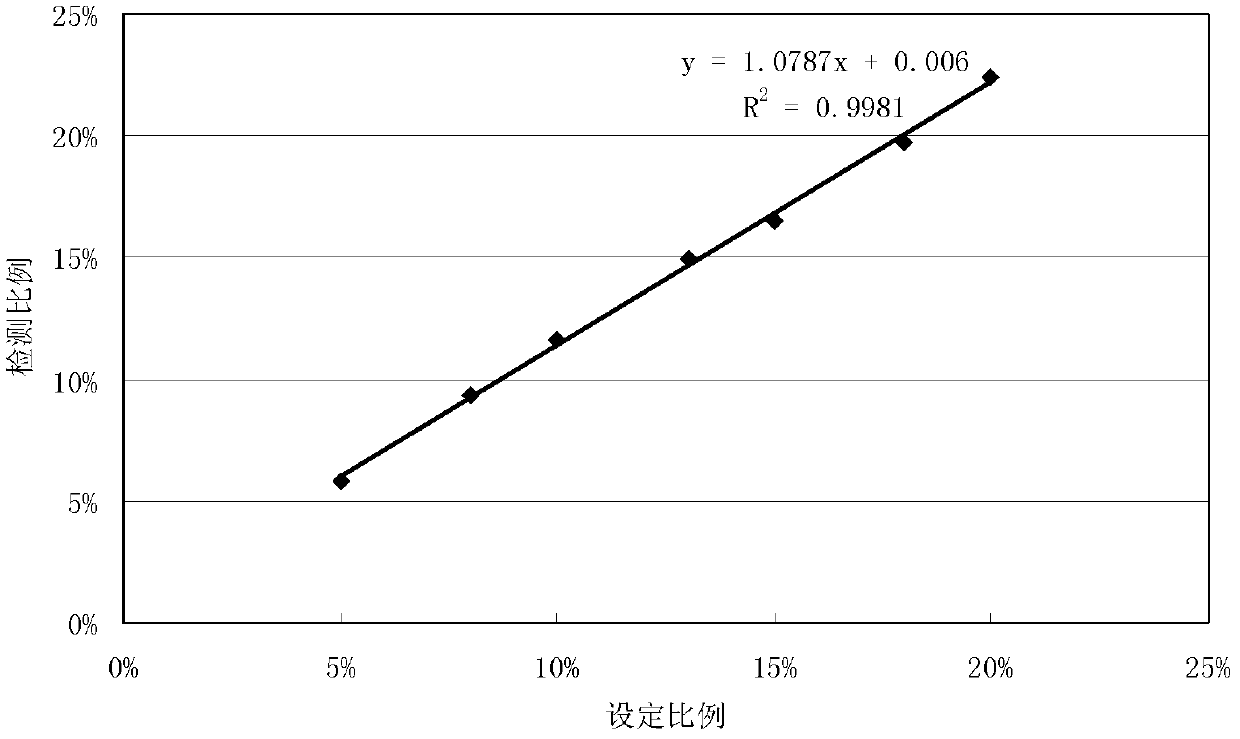

[0036] 1. Taking the expanded shredded tobacco as a marker, accurately weigh each component of the corresponding multiple groups of shredded tobacco according to the different setting ratio x (i.e. the actual mixing ratio) of the expanded shredded leaf, and then carry out all the components of each group of shredded tobacco Manual mixing, the weight of each group of mixed shredded tobacco is 10g; after drying, weigh accurately, put the shredded tobacco into a beaker of 1000ml (10g mixture needs 1000ml for actual operation) filled with cyclohexane, stir it with a glass rod, and let it stand for 1 minute Finally, use a steel wire filter spoon to fish out the upper layer components, let it air in the fume hood for 5 minutes, remove a small amount of shredded stems, dry and weigh accurately, and calculate the ratio y of expanded shredded leaves in shredded tobacco. Establish a standard curve between the detected ratio and the set ratio: y=1.0787x+0.006, as shown in Figure (1).

[...

Embodiment 2

[0041] 1. Taking the expanded shredded tobacco as a marker, accurately weigh each component of the corresponding multiple groups of shredded tobacco according to the different setting ratio x (i.e. the actual mixing ratio) of the expanded shredded leaf, and then carry out all the components of each group of shredded tobacco Manual mixing, the weight of each group of mixed cut tobacco is 15g; after drying, weigh accurately, put the cut tobacco into a 1000ml beaker filled with acetone, stir with a glass rod, and after standing for 1 minute, use a steel wire filter spoon to scoop out the upper layer components and ventilate After airing in the cupboard for 5 minutes, remove a small amount of shredded stems, dry them and weigh them accurately, and calculate the ratio y of the expanded shredded leaves in the shredded tobacco. Establish a standard curve between the detected ratio and the set ratio: y=1.0787x+0.006, as shown in Figure (1).

[0042] 2. Pick up the mixed shredded tobac...

Embodiment 3

[0047] 1. Taking the expanded shredded tobacco as a marker, accurately weigh each component of the corresponding multiple groups of shredded tobacco according to the different setting ratio x (i.e. the actual mixing ratio) of the expanded shredded leaf, and then carry out all the components of each group of shredded tobacco Manual mixing, the weight of each group of mixed cut tobacco is 5g; after drying, weigh accurately, put the cut tobacco into a 1000ml beaker filled with ethanol, stir with a glass rod, and after standing for 1 minute, use a steel wire filter spoon to scoop out the upper component and ventilate After airing in the cupboard for 5 minutes, remove a small amount of shredded stems, dry them and weigh them accurately, and calculate the ratio y of the expanded shredded leaves in the shredded tobacco. Establish a standard curve between the detected ratio and the set ratio: y=1.0787x+0.006, as shown in Figure (1).

[0048] 2. Sampling 1 pack of cigarettes each time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com