Production process of novel chicken soup-stock

A production process, chicken broth technology, applied in the fields of food science, food ingredients, irradiation, etc., can solve the problems of poor stability, low production efficiency, sterilization, hygiene, nutrition and taste that are difficult to guarantee, and achieve stable taste and improve production. Efficiency, the effect of meeting a wide range of needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

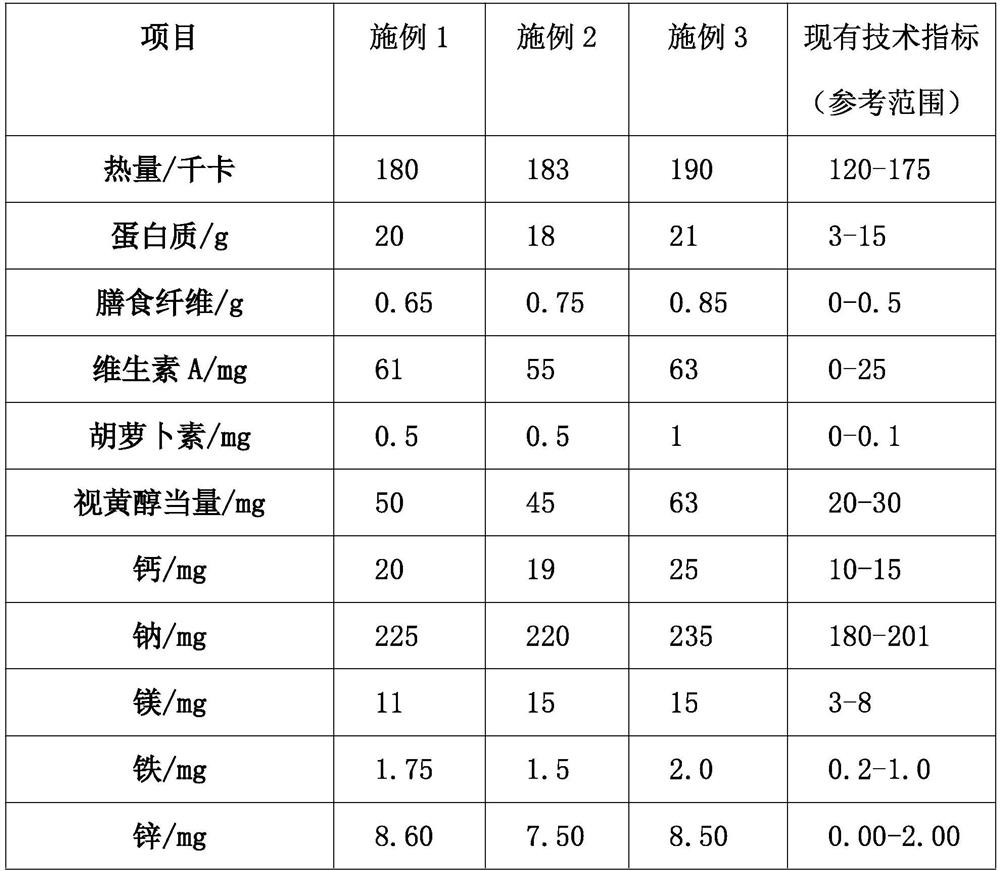

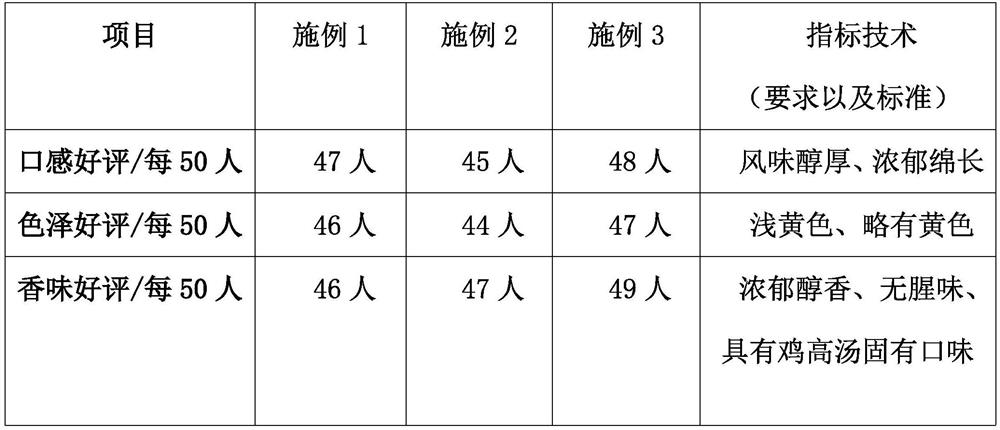

Embodiment 1

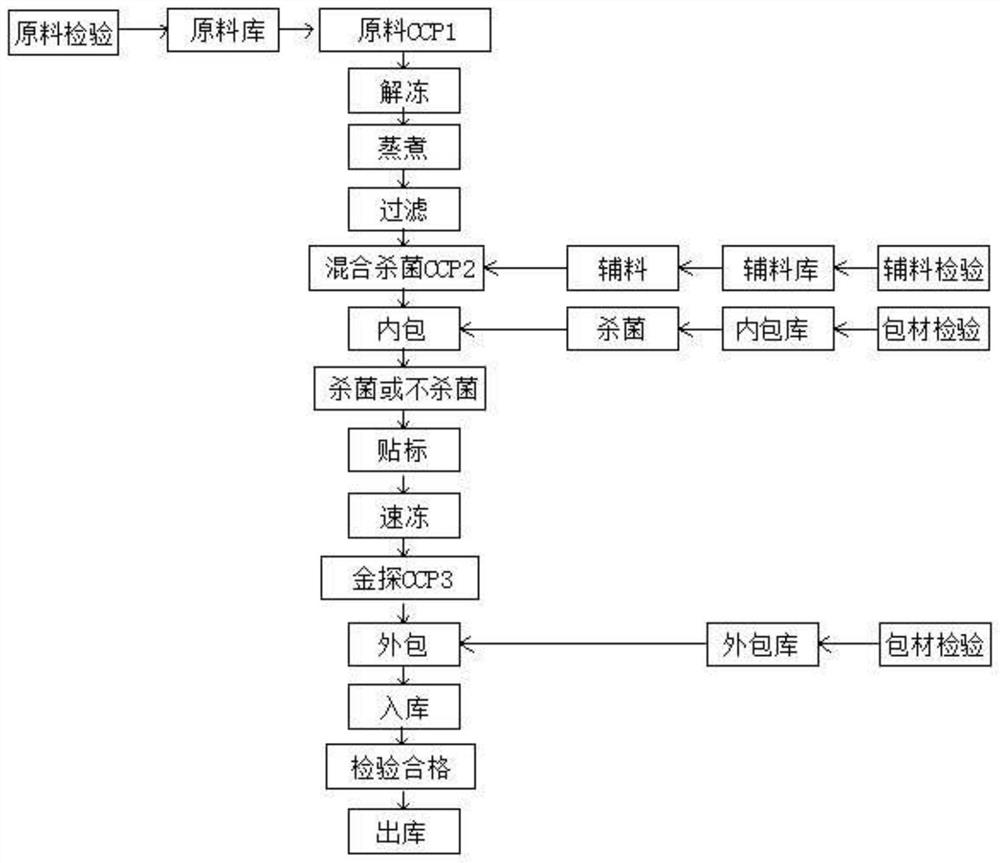

[0031] refer to figure 1 , In this embodiment, a production process of a new type of chicken stock is proposed, which includes the following steps: raw material inspection → raw material warehouse → raw material CCP1 → thawing → cooking → filtration → mixed sterilization CCP2 → internal packaging → sterilization or non-sterilization → labeling → quick freezing →Gold Detector CCP3 →Outsourcing →Inbound →Inspection Qualified →Outbound;

[0032] In the described raw material CCP1 step, the main raw material is old hens, and in order to ensure the control point of food safety, old hens that are naturally stocked for 3-5 years are selected;

[0033] In the thawing step, the thawing time is 2-3h, and it is thawed in warm water at 30-45°C to a natural state of relaxation;

[0034] In the described cooking step, the thawed qualified old hens are re-added with water and then boiled for more than 6 hours until the marrow overflows;

[0035] In the described filtering step, the chicken...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is:

[0054] In this example, in the described raw material CCP1 step, the main raw material is old hens, and in order to ensure the control point of food pollution-free pollution, old hens that have been raised naturally for 5 years are selected; and the stocking food of old hens is various insects in the wilderness , and the combination of natural agricultural grains.

[0055] In this example, in the thawing step, the thawing time is 2 hours, and the thawing is performed in warm water at 32° C. to a natural state of relaxation.

[0056] In this example, in the cooking step, add water to the thawed qualified old hens, and cook them successively with high fire for 0.25 hours, medium fire for 0.5 hours, and low fire for 5.5 hours until the bone marrow overflows.

[0057] In this example, in the mixed sterilization CCP2 step, the auxiliary materials include the following percentages of raw materials: 5% of diced ham...

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is:

[0062] In this example, in the thawing step, the thawing time is 2.5 hours, and the thawing time is 30° C. warm water to a natural state of relaxation.

[0063] In this example, in the cooking step, add water to the thawed qualified old hens, and cook them successively with high fire for 0.25-0.5h, medium fire for 0.5-1.5h, and low fire for 4.5-8h until the bone marrow overflows.

[0064] In this example, in the mixed sterilization CCP2 step, the auxiliary materials include the following percentages of raw materials: 5% of diced ham, 6% of diced onion, 0.7% of minced ginger, 0.7% of minced shallot, 0.2% of anise, and 1% of wolfberry , 1% salt, 0.35% monosodium glutamate, 1.5% cooking wine, 2% starch;

[0065] In its mixing and sterilization: add the auxiliary materials to the filtered chicken soup and stir it with a mixer for 9 minutes. In order to ensure the control point of food safety: the auxiliary mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com