Grooved beam

A technology with grooves and channel steel, which is applied in the direction of joists, girders, trusses, etc., and can solve the problem of occupying a lot of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

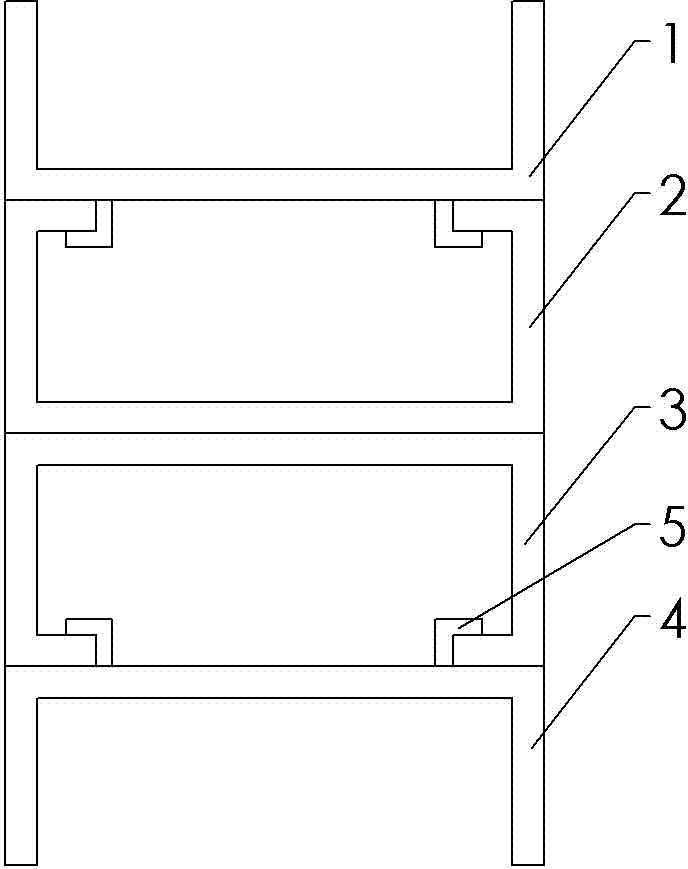

[0010] Including upper channel steel 1, upper c-shaped steel 2, lower c-shaped steel 3 and lower channel steel 4 stacked from top to bottom, in which two c-shaped steel webs are back-attached and connected, and the webs of the upper channel steel and the lower channel steel are respectively It is connected with adjacent c-shaped steel coils, and the outer surface of the web of the upper channel steel and the lower channel steel is welded with a strip-shaped connecting ear 5 with an L-shaped cross-section. The connecting ears are two and correspond to two coiled edges on a c-shaped steel , the connecting ear is surrounded by the webs of the upper channel steel and the lower channel steel to form a connecting slot for fastening the c-shaped steel coil ear, and the c-shaped steel coil ear can be inserted and fixed in the connecting slot, and the c-shaped steel and the groove The steel web encloses a groove-shaped channel, and at the same time, in order to further strengthen the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com