Rapid ball-feeding firing mechanism

A firing mechanism and fast technology, applied to weapons that do not use explosives, weapon types, offensive equipment, etc., can solve problems such as damage, easy jamming of the bomb feeding structure, and large gas source consumption, so as to increase the speed of feeding bombs, improve the The effect of quickly replenishing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

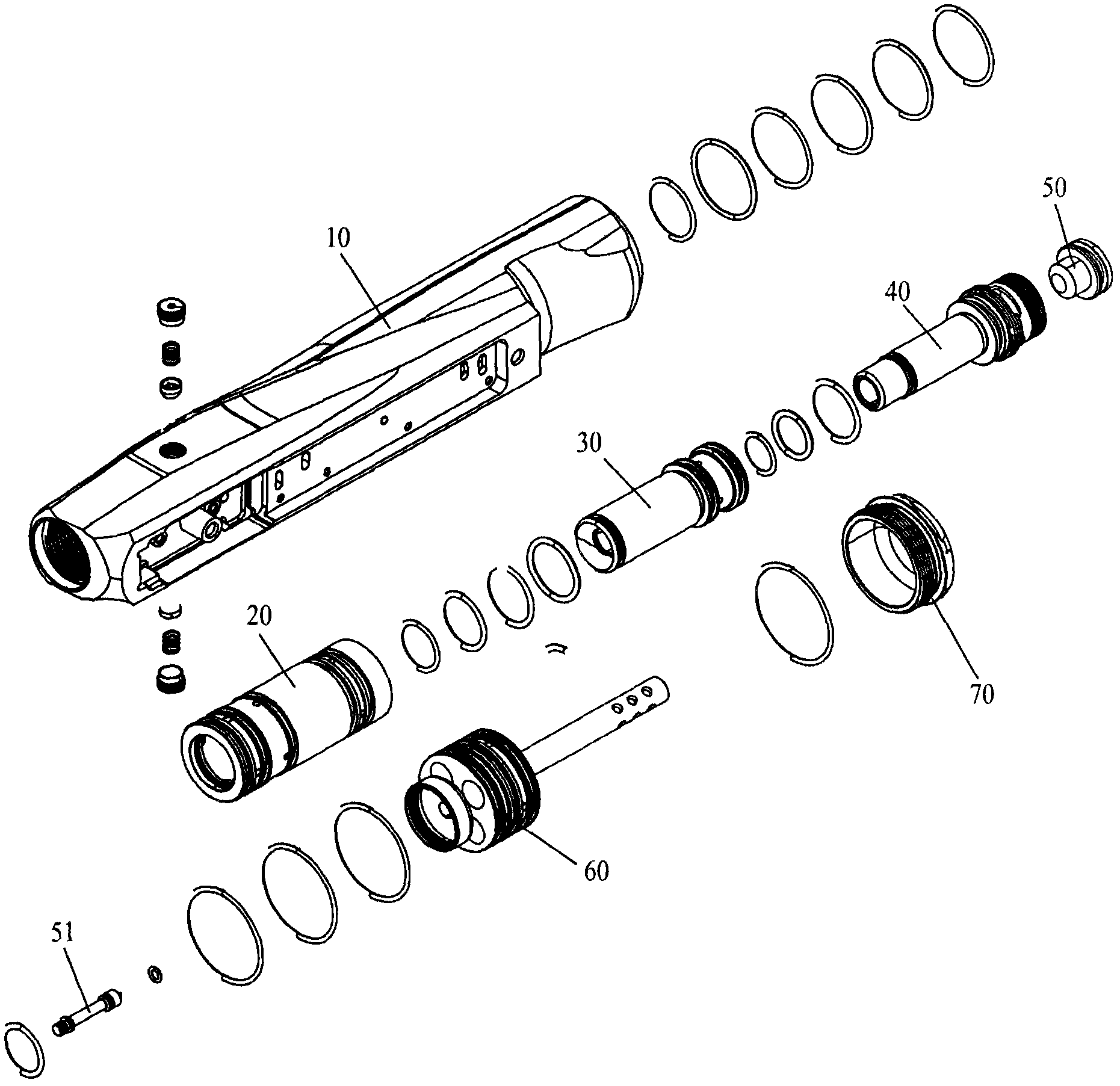

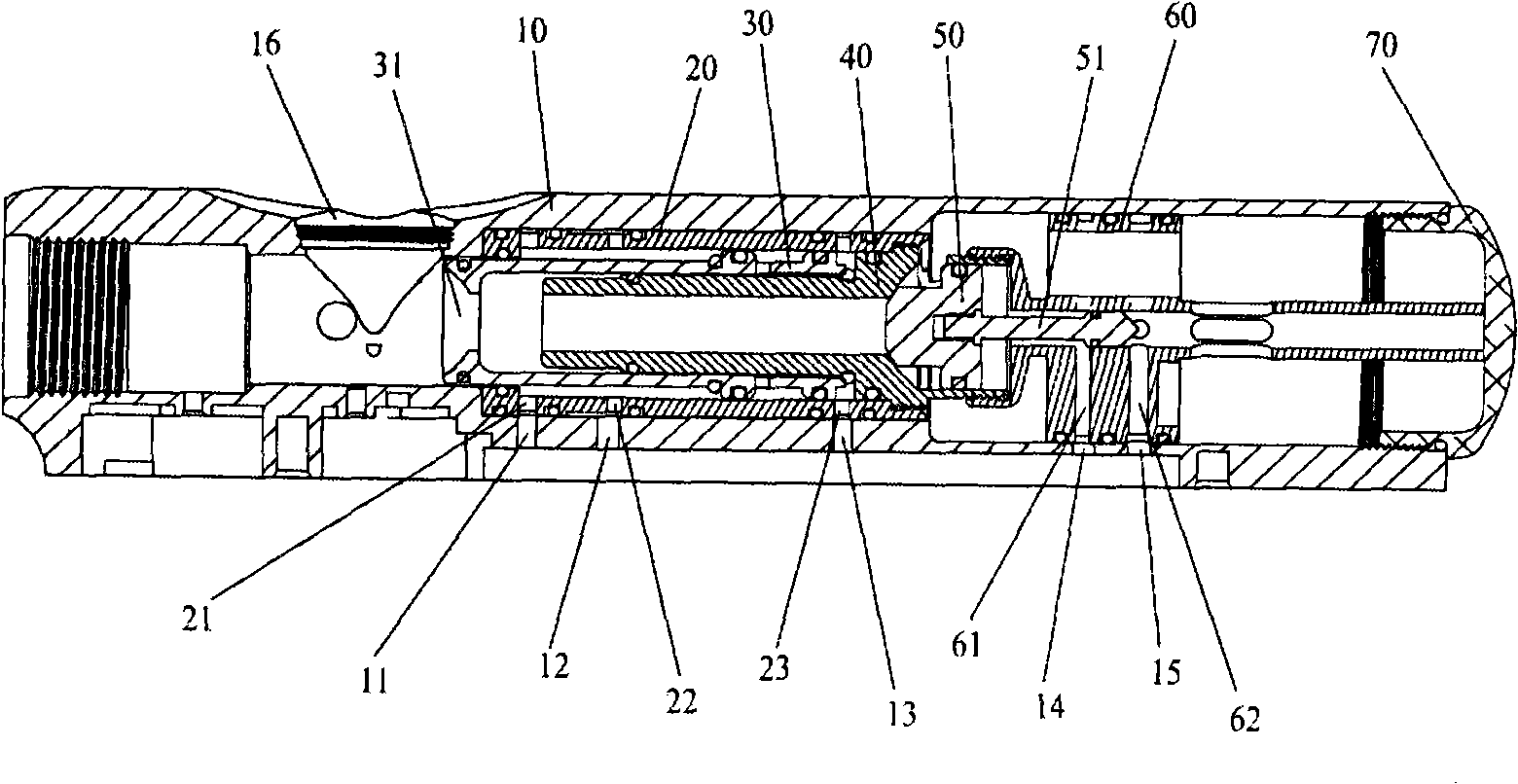

[0016] see figure 1 and figure 2 , figure 1 The exploded perspective view of the present invention, figure 2 The combined sectional view of the present invention. An inner liner 20 is set at the hollow inner end of the gun body 10 of the paintball gun, and a push rod 30 is set in the inner liner 20 for sealing and sliding fit, and a row fixed with the inner liner 20 is set at the inner end of the push rod 30 The air seat 40 is equipped with a movable valve 50 at the rear end of the exhaust seat 40, and a driven valve stem 51 is fixedly arranged at the movable valve 50 end, and a valve seat 60 is arranged at the outer end of the movable valve 50, and the gun body 10 A rear cover 70 is fixedly arranged at the rear end to form a paintball gun structure with fast feeding and firing.

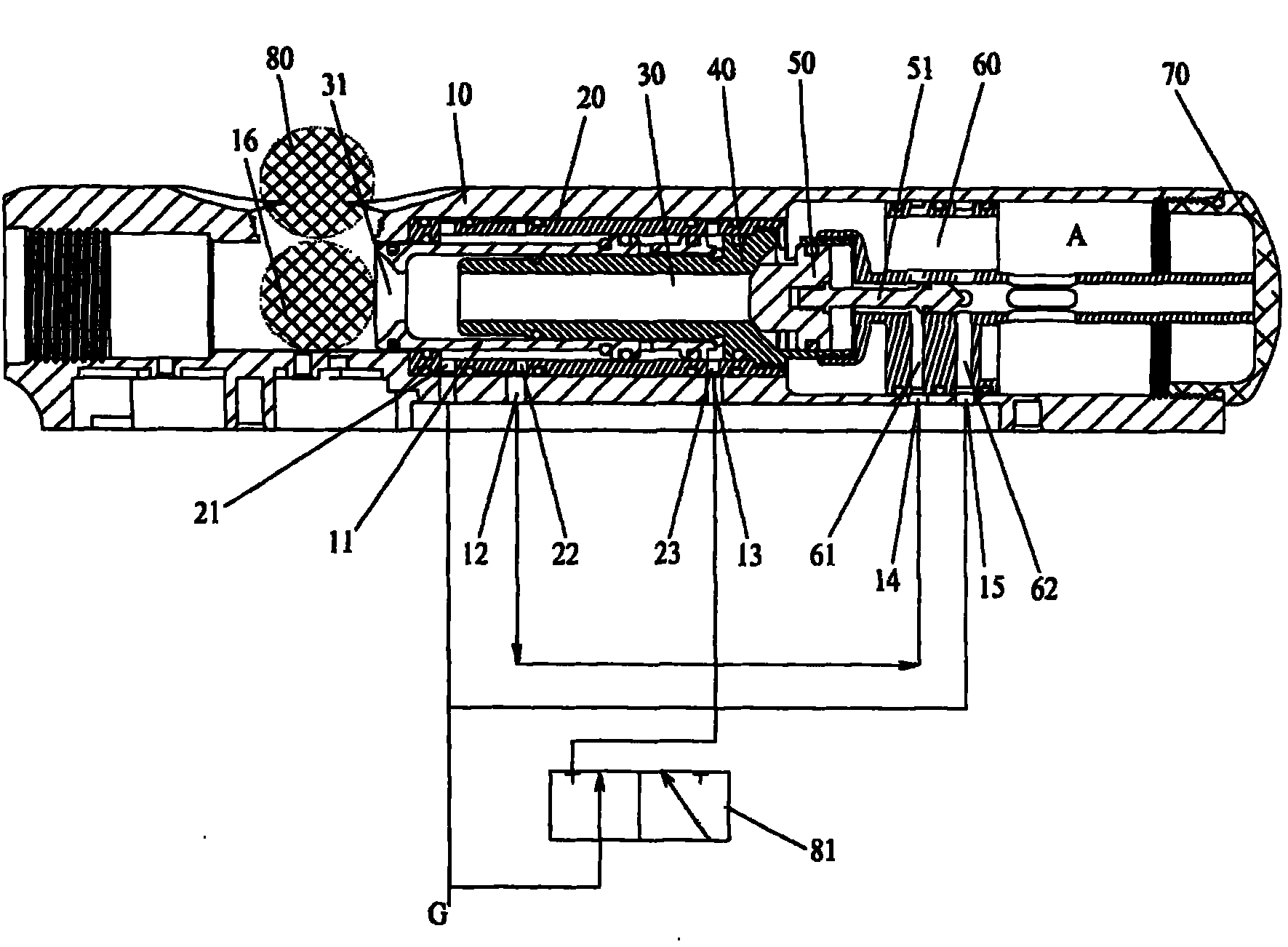

[0017] see again Figure 3 to Figure 5 , Figure 3 to Figure 5 It is a schematic diagram of the implementation of the invention; several air inlets 11, air source holes 12, 13, 14, 15 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com