A continuous casting mold powder for ultra-low carbon steel

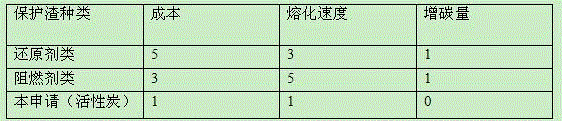

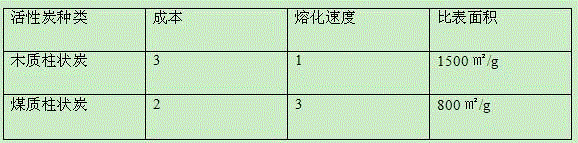

A continuous casting crystallizer and ultra-low carbon steel technology, applied in the field of steelmaking auxiliary materials, can solve the problems of increasing the sintering tendency of mold slag, affecting the melting speed, and high price, so as to prevent the carbonization of ultra-low carbon steel and avoid excessive The effect of carbon increase and strong adsorption function of low carbon steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] For the ultra-low carbon steel of Plant A, the raw material formula of mold powder for continuous casting mold of the present invention is: 15.8 parts of glass powder, 48 parts of wollastonite, 11.2 parts of fluorite, 4.8 parts of cement clinker, 2 parts of activated carbon, and sodium carbonate 4.1 parts, 4.5 parts of sodium fluoride, 3 parts of spodumene, 1 part of lithium carbonate, 1.9 parts of binder, 3.7 parts of lightly burned magnesia.

[0030] The test results of its main physical and chemical indicators are as follows: CaO: 31.89%, SiO 2 : 35.24%, MgO: 4.9%, Al 2 o 3 : 3.7%, Na 2 O: 8.5%, F - : 8.6%, C: 3.2%.

[0031] The basicity of the present invention is CaO / SiO 2 It is 0.9, the melting point is 1093°C and the viscosity is 0.39Pa.s at 1300°C.

[0032] When starting to pour, push the adjusted mold slag into the mold. After observation, the fluctuation of the liquid steel level is within 3mm, and the casting speed is stable at 0.6m / min. At this time, t...

Embodiment example 2

[0034] The raw material formula of mold flux used for ultra-low carbon steel in Plant B is: 14.8 parts of glass powder, 45.8 parts of wollastonite, 13.1 parts of fluorite, 5.5 parts of cement clinker, 2 parts of activated carbon, 5.3 parts of sodium carbonate, fluoride 4.5 parts of sodium, 3 parts of spodumene, 1 part of lithium carbonate, 1.9 parts of binder, 3.1 parts of lightly burned magnesia.

[0035] The test results of its main physical and chemical indicators are as follows: CaO: 34.9%, SiO 2 : 33.2%, MgO: 3.5%, Al 2 o 3 : 4.2%, Na 2 O: 7.2%, F - : 5.3%, C: 3.3%.

[0036] The alkalinity of the mold flux of the present invention is CaO / SiO 2 It is 1.05, the melting point is 1131°C, and the viscosity is 0.46Pa.s at 1300°C.

[0037] When pouring starts, the adjusted mold slag is pushed into the mold. After observation, the liquid steel level fluctuates within 3mm, and the casting speed is stable at 0.6m / min. At this time, the thickness of the liquid slag layer is me...

Embodiment example 3

[0039] Our company produces mold powder for continuous casting mold for ultra-low carbon steel in plant C. The raw material formula is: 20 parts of glass powder, 52 parts of wollastonite, 12.7 parts of fluorite, 5.5 parts of cement clinker, and 2 parts of activated carbon , 4.8 parts of sodium carbonate, 4.5 parts of sodium fluoride, 3 parts of spodumene, 1 part of lithium carbonate, 1 part of binder, and 5 parts of lightly burned magnesia.

[0040] The test results of its main physical and chemical indicators are as follows: CaO: 34.13%, SiO 2 : 36.7%, MgO: 6.1%, Al 2 o 3 : 2.9%, Na 2 O: 7.8%, F - : 6.6%, C: 3.5%.

[0041] The basicity of the present invention is CaO / SiO 2 It is 0.92, the melting point is 1075°C and the viscosity is 0.33Pa.s at 1300°C.

[0042] When pouring starts, the adjusted mold slag is pushed into the mold. After observation, the liquid steel level fluctuation is within 3mm, and the casting speed is stable at 0.6m / min. At this time, the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com