Bionic dolphin skin based on shape memory alloy artificial muscle

An artificial muscle and memory alloy technology, applied in the field of engineering bionics, to achieve the effect of sensitive elastic working mechanism and durable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

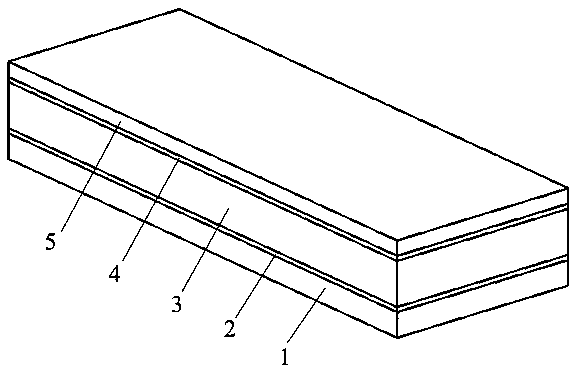

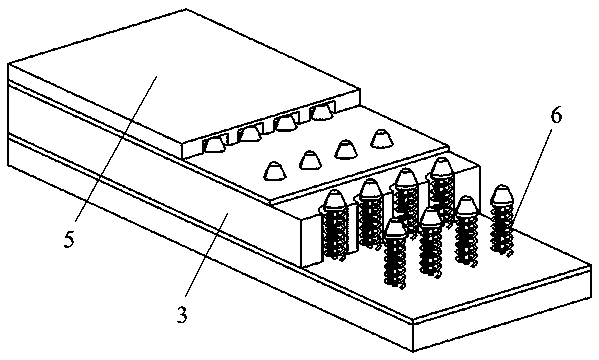

[0025] Specific embodiment one: with reference to figure 1 , figure 2 with Figure 6A , The shape memory alloy used to make the shape memory alloy artificial muscle spring 7 is a nickel-titanium alloy with a two-way memory effect, and its transformation temperature is 55°C. When making the shape memory alloy artificial muscle spring 7, it is first processed into a thin and elongated compression spring shape with a height of 5.0mm when the temperature is higher than 55°C, and then artificially deformed into a shape with a height of 2.5mm when the temperature is lower than 55°C. Stubby compression spring shape.

[0026] It is planned to apply the bionic dolphin skin to a certain type of motor boat (length 3.2m) that is active in the offshore all year round. The length of the bionic dolphin skin is 2.0m. First, according to the usual working environment of this type of motorboat (seawater temperature 20°C, density 1.025×10 3 kg / m 3 , The dynamic viscosity is 1.002×10 -3 kg...

specific Embodiment 2

[0029] Specific embodiment two: with reference to figure 1 , figure 2 with Figure 6B , if the shape memory alloy used to make the shape memory alloy artificial muscle spring 7 is a nickel-titanium alloy with two-way memory effect, its transition temperature is 55°C. When making the shape memory alloy artificial muscle spring 7, first process it into a short and thick compression spring shape with a height of 2.5mm when the temperature is higher than 55°C, and then artificially deform it into a height of 5.0mm when the temperature is lower than 55°C slim compression spring shape.

[0030] The bionic dolphin skin is also applied to a certain type of motor boat (length 3.2m) that is active in the offshore all year round, and the laying length of the bionic dolphin skin is 2.0m. First of all, according to the usual working environment of this type of motorboat (seawater temperature 20°C, density 1.025×10 3 kg / m 3 , The dynamic viscosity is 1.002×10 -3 kg / m s) to calculate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com