A double oil cylinder jacking mechanism for a tower crane body

The technology of a jacking mechanism and double oil cylinders is applied in cranes and other directions, which can solve the problems of tower crane instability, falling tower, large force and easy deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

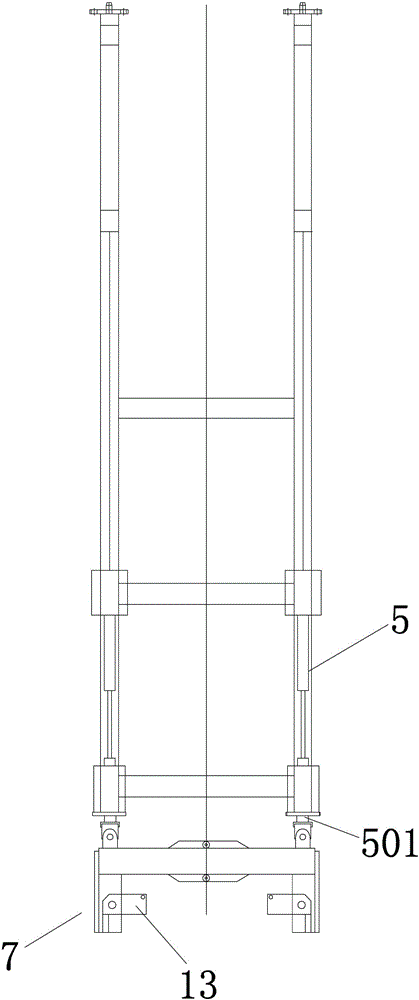

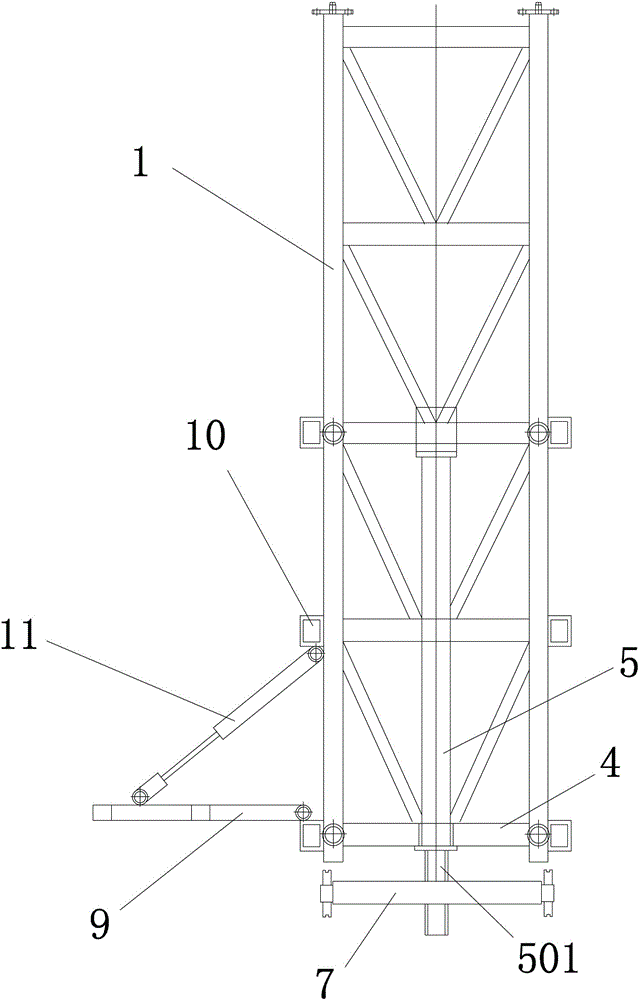

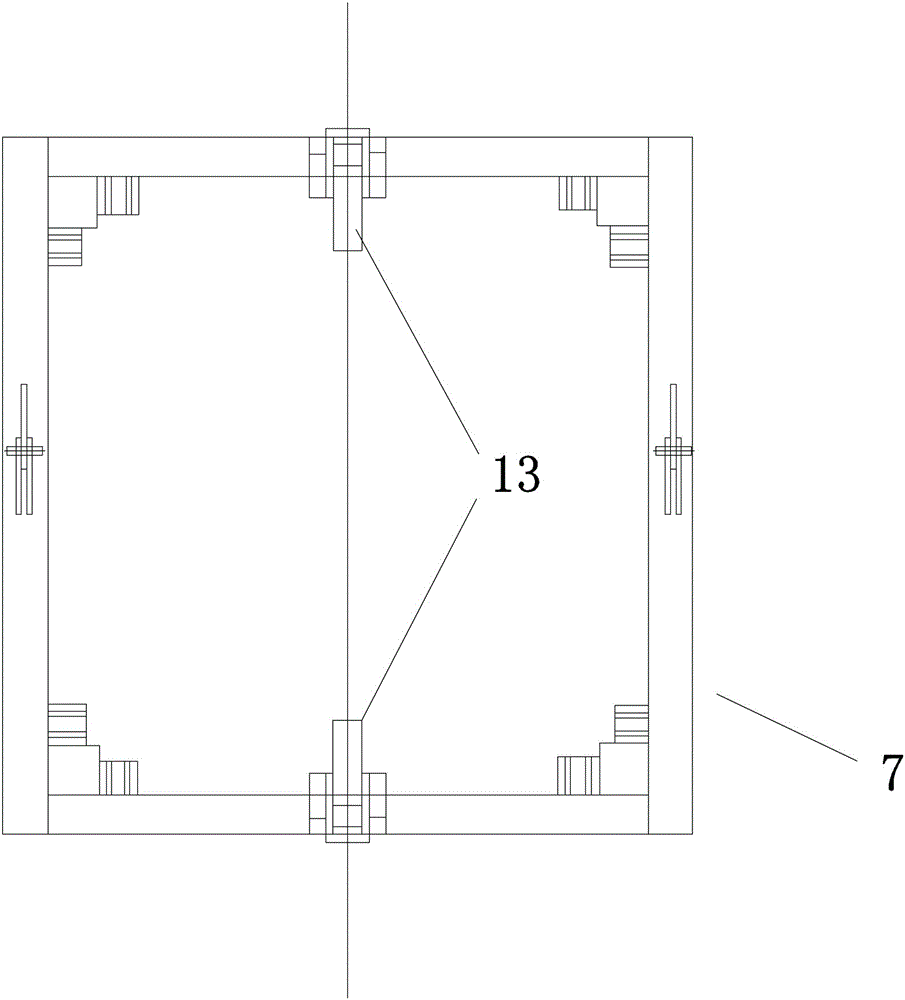

[0020] Embodiment 1: see attached figure 1 to attach Figure 6 As shown, the tower crane tower body double cylinder jacking mechanism described in this embodiment includes a jacking outer frame 1 and a standard section 2, and a guide mechanism 3 is provided between the jacking outer frame 1 and the standard section 2, Jacking oil cylinders 5 are fixedly installed on two opposite sides of the jacking jacket frame 1, and the cylinder blocks of the two jacking oil cylinders 5 are fixed to the side beams of the jacking jacket frame 1, and the protruding ends of the pistons face downward, Lifting support device 7 is fixedly connected on the piston rod of lifting oil cylinder 5, and this lifting support device 7 is to be fixedly connected by pin by two U-shaped frames, constitutes frame-shaped connection support, and is installed below the opposite two sides of support. The connecting crawling claw 13 that swings up and down, the connecting crawling claw 13 can swing upwards to the...

Embodiment 2

[0022] Embodiment 2: see attached Figure 7 to attach Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the jacking support device 7 is provided with a rotating claw 12 that can rotate in the horizontal direction, which can rotate in the horizontal direction, and the rotating claw 12 can rotate to the original standard. Above the crossbeam of section 2 and form a support with the horizontal beam, when the jacking operation is to be carried out, the rotating claw 12 is rotated 90 degrees in the direction of the tower, so that the rotating claw 12 is offset against the horizontal beam of the original standard section 2 , during the jacking process, the pressure is transmitted to the horizontal beam of the original standard section 2 through the rotating claw 12 to realize the jacking operation; Climbing claw 12 breaks away from the horizontal crossbeam of original standard section 2, can flexibly switch the working state of jacking up and not j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com