POP paster device and chip removing jig

A patch device and chip technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

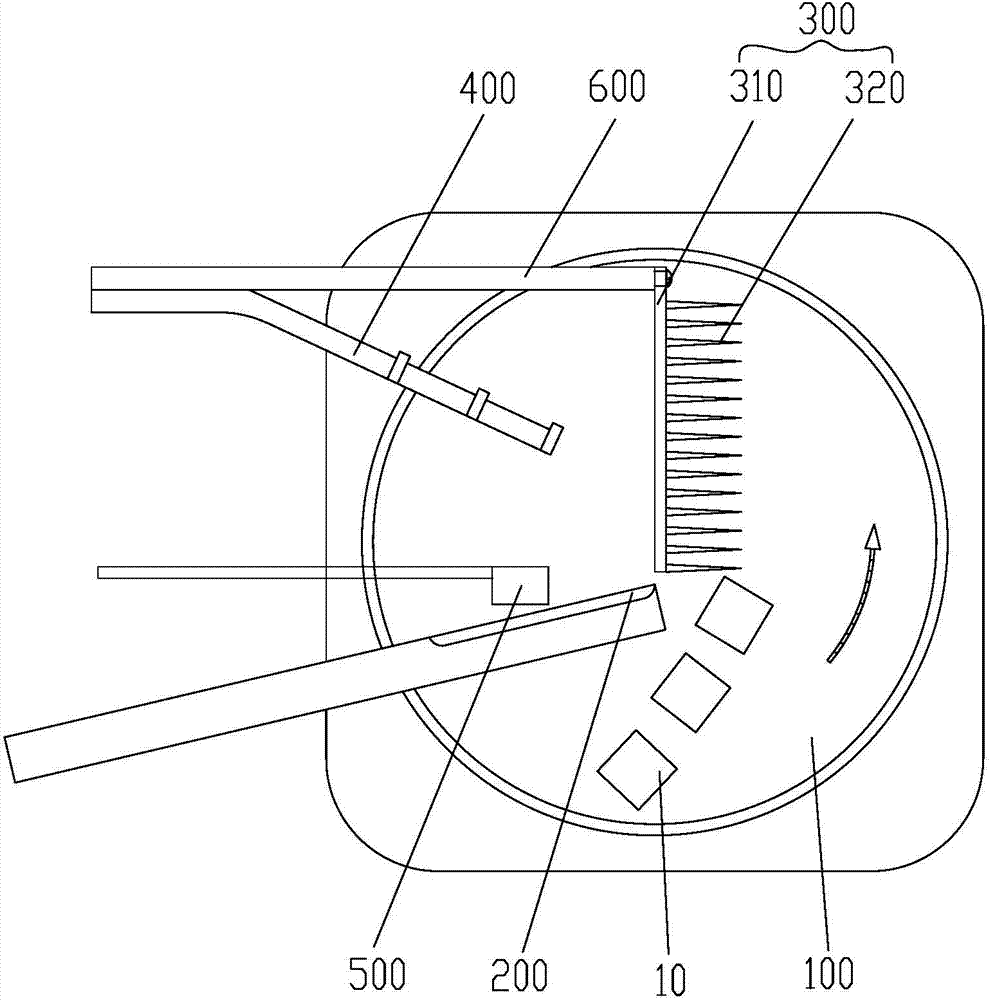

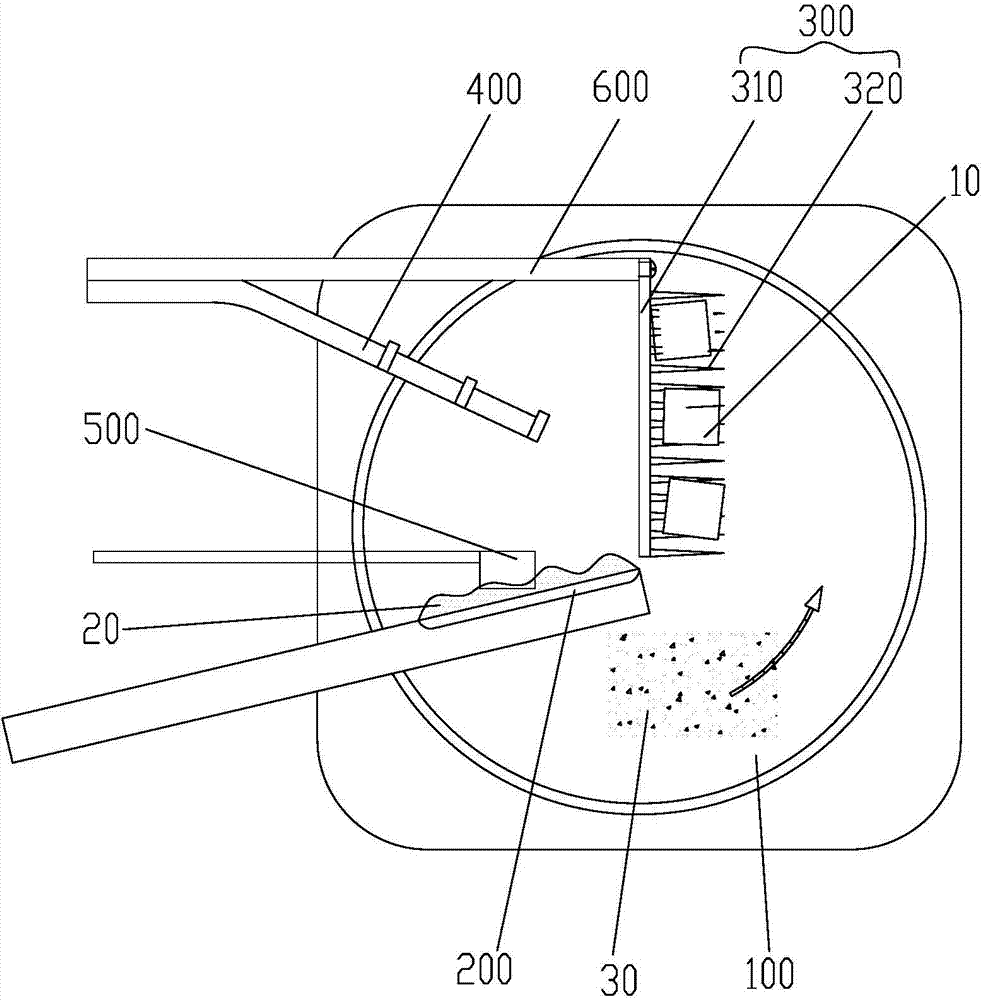

[0026] refer to figure 1 , figure 2 , a POP placement device, including a turntable 100, and a scraper 200 and a chip removal jig 300 arranged above the turntable 100, the chip removal jig 300 includes a horizontal frame 310, a plurality of bar 320, the bar 320 are installed on the horizontal frame 310 at intervals, and the end of the bar 320 away from the horizontal frame 310 is in contact with the surface of the turntable 100 or slightly higher than the surface of the turntable 100 , and it is opposite to the direction in which the turntable 100 rotates.

[0027] The POP placement device described in this embodiment, by setting the chip removal jig 300 on the turntable 100, once the chip 10 falls off into the turntable 100 when the flux is dipped in the flux area 30, the chip 10 will be removed immediately. The turntable 100 rotates to the chip removal ji...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com