A device for fatigue testing of fork

A fatigue test and fork technology, which is applied in the design field of helicopter fork fatigue test device, can solve the problems of lack of fork fatigue test device and inability to test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below.

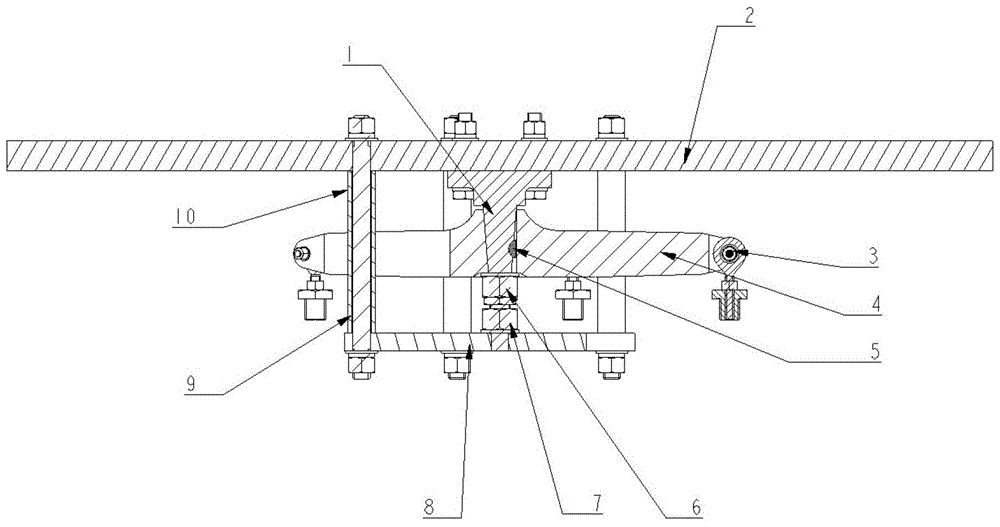

[0009] Such as figure 1 As shown, the present invention is a fork-shaped member fatigue test device, comprising: a simulated shaft 1, a top plate 2, a joint bearing assembly 3, a fork-shaped member 4, a key 5, an adjusting nut 6, a limit nut 7, a lower bottom plate 8, The bolt 9 and the support sleeve 10 are composed of the fork 4 inserted into the simulation shaft 1, which has threads on the simulation shaft 1, the position of the fork 4 on the simulation shaft 1 is adjusted by the adjustment nut 6, and the center of the lower bottom plate 8 has a hole, which simulates The end of the shaft 1 is inserted into the hole, and the installation position of the lower bottom plate 8 is adjusted through the limit nut 7. There are holes around the lower bottom plate 8, which are connected with the top plate 2 through bolts 9 and support sleeves 10, and tightened with mounting nuts. Joint bearings Assembly 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com