A centrifugal force loading device for a bearingless rotor flexible beam

A loading device and centrifugal force technology, applied in the testing of measuring devices, instruments, mechanical parts, etc., can solve the problem of no main propeller, bearingless rotor flexible beam fatigue test device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

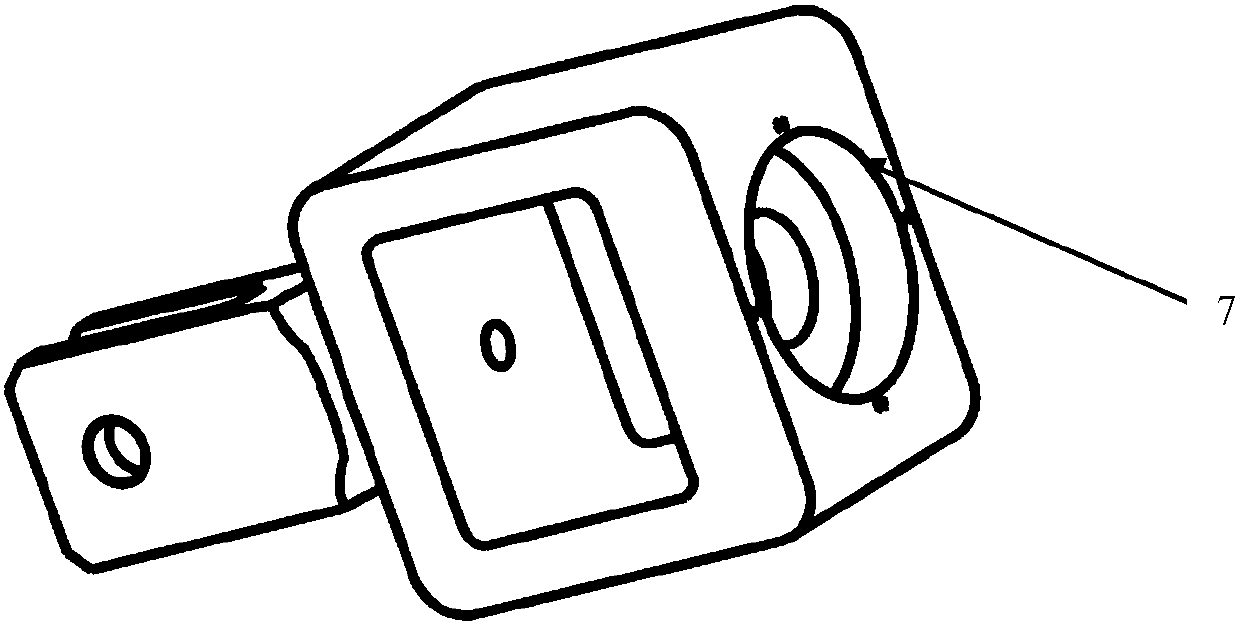

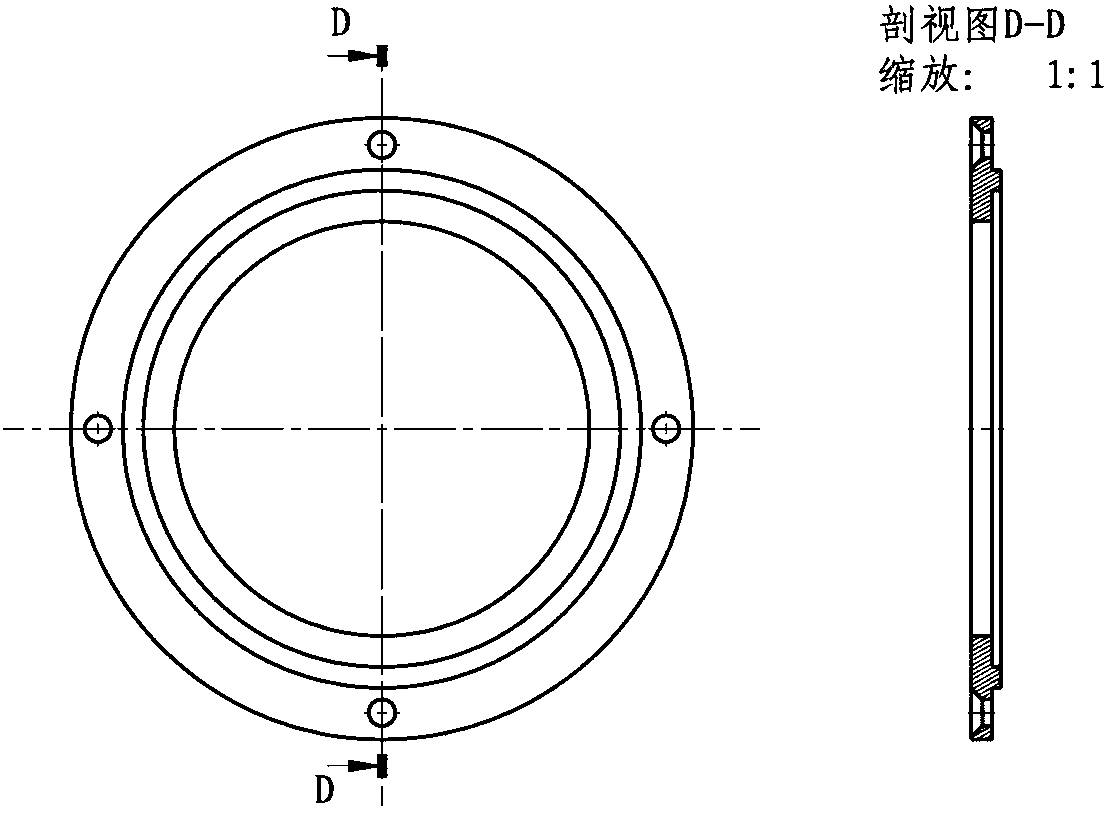

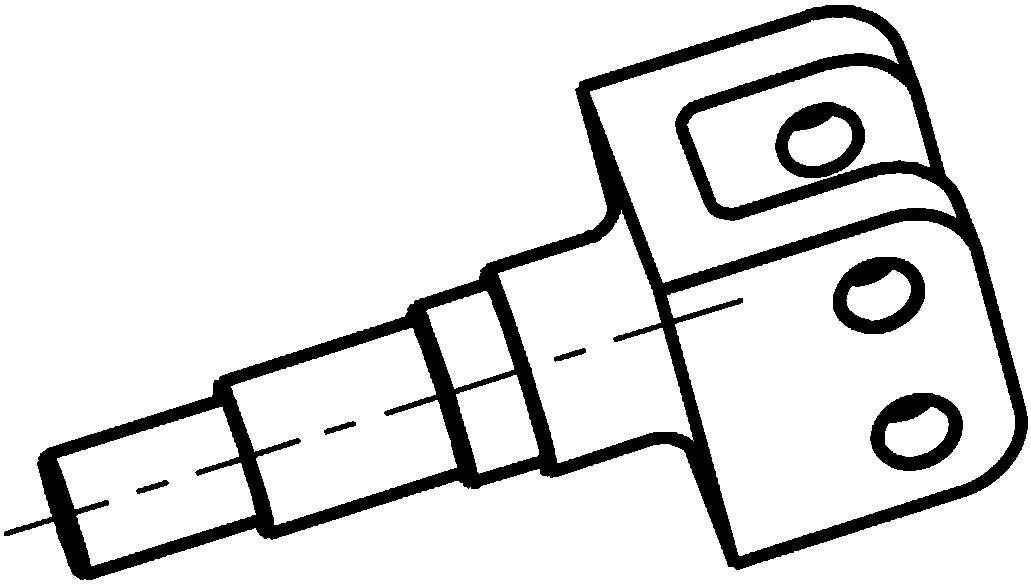

[0019] see below Figure 4 , Figure 5 The present invention is described in further detail. The bearingless rotor flexible beam centrifugal force loading device is composed of a centrifugal force outer frame 1, a thrust ball bearing 2, a rolling bearing 3, a cover plate 4, a flexible beam joint 5, and a lock nut 6; it is characterized in that the centrifugal force outer frame 1 is a frame Structure, the frame structure is symmetrical up and down, with a bearing installation hole on one side, the axis of the bearing installation hole is located on the intersection line of the symmetry plane of the centrifugal force outer frame 1, one end of the flexible beam joint 5 is a stepped rotating shaft, and the cover plate 4 is Circular boss structure with a through hole in the middle, the rolling bearing 3 is installed on the bearing installation hole of the centrifugal force outer frame 1, the boss of the cover plate 4 is pressed on the outer ring of the rolling bearing 3, the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com