Forklift arm special for aluminum plate transportation and forklift with forklift arm

A forklift and aluminum plate technology, which is applied in the field of special forklift arms for aluminum plate transportation, can solve the problems of increased labor costs for enterprises, hidden safety hazards of manual unloading, and high quality of aluminum plates, and achieve the effects of reduced friction, high unloading efficiency, and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

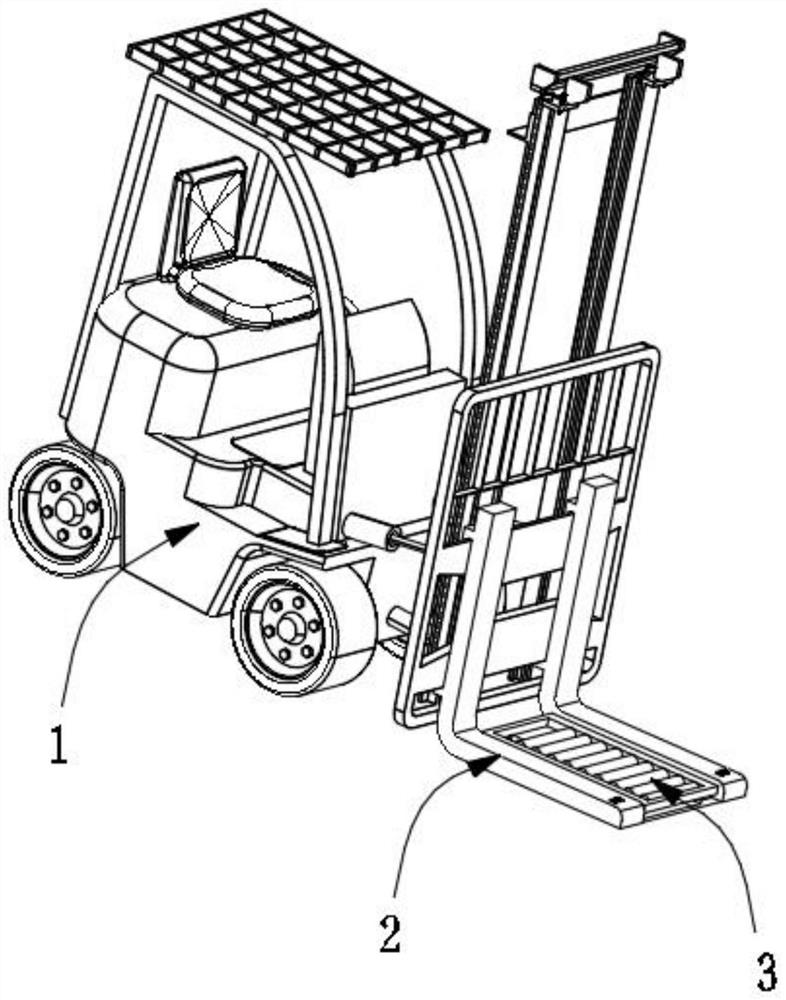

[0030] see Figure 1-Figure 4 , a special forklift arm for aluminum plate transportation in this embodiment, including:

[0031] A set of cantilevers 2 connected to the main body 1 of the forklift;

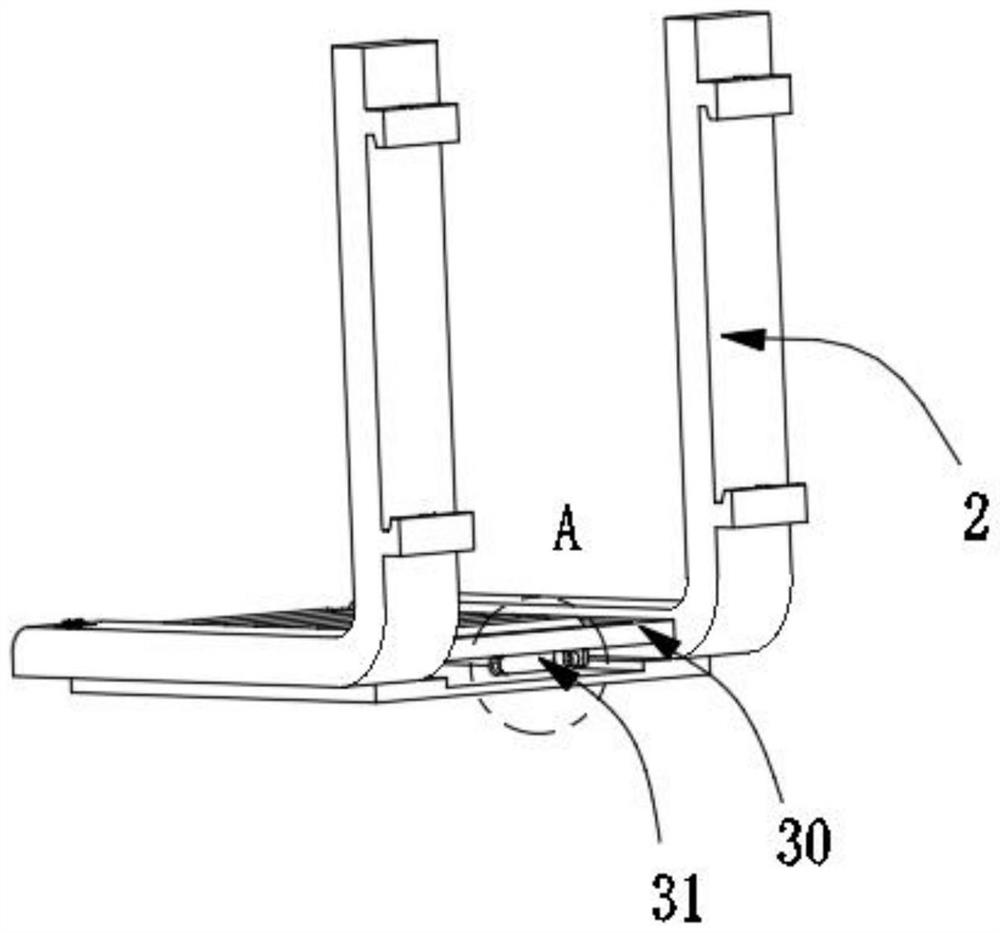

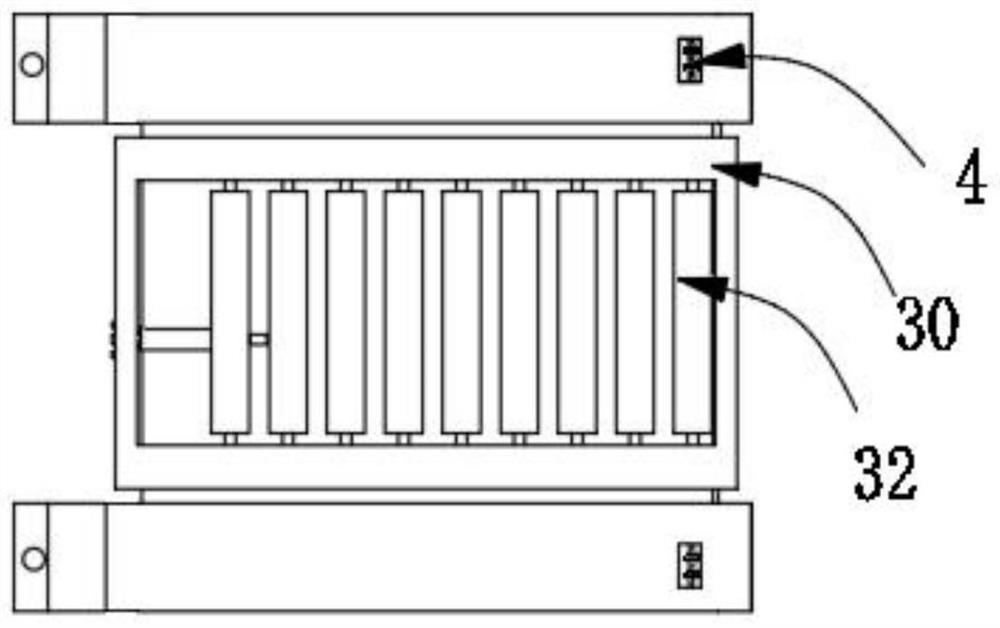

[0032] Rolling assembly 3. The rolling assembly 3 is arranged between a set of cantilevers 2. The rolling assembly 3 includes an oil cylinder 31 and a rolling element. One end of the rolling element away from the forklift is rotatably connected to the cantilever 2, and the other end is connected to the driving end of the oil cylinder 31. The oil cylinder 31 is connected to the hydraulic system of the forklift main body 1 .

[0033] The rolling element has a first state and a second state under the driving of the oil cylinder 31. It should be noted that when the oil cylinder 31 is arranged below the rolling element, the first state is the extended state of the oil cylinder 31, and the second state is the extended state of the oil cylinder 31. In the retracted state of the oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com