A lower body of a plastic model with a heel and its manufacturing method

A production method and technology for shoe heels, which are applied to dummies, household appliances, applications, etc., can solve the problems of affecting the display effect, affecting the aesthetic effect of trouser legs, and the production method being unsuitable for the production of the present invention, and achieving the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

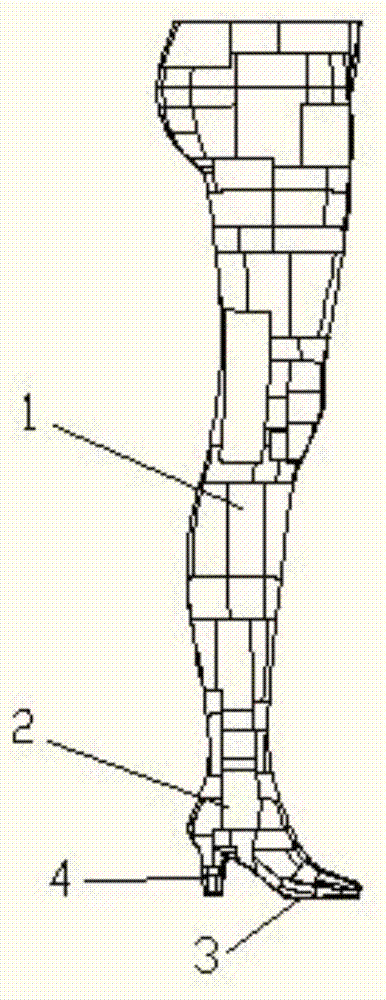

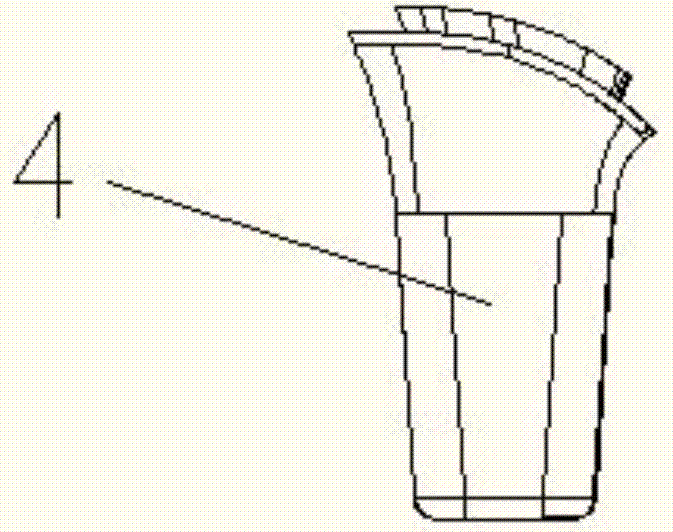

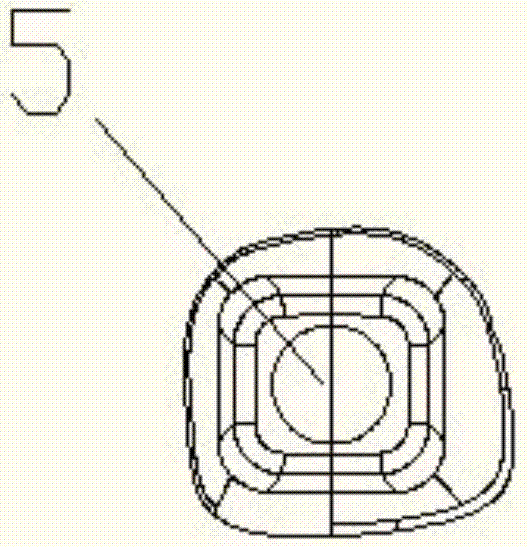

[0031] see Figure 1-Figure 3 As shown, a lower body of a plastic model with a heel includes two legs 1 and a foot 2 connected as one, wherein the foot 2 is shaped like a shoe and is divided into a sole 3 and a heel 4. The front end surface of the sole 3 and the bottom surface of the heel 4 are on the same horizontal line, and the bottom surfaces of the two feet 3 are on the same parallel line or two parallel horizontal lines; the inner wall of the heel 4 forms an accommodating The hollow structure 5 in which the support frame is directly inserted, the center line of the hollow structure 5 is perpendicular to the horizontal ground.

[0032] The above-mentioned support frame is compatible w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com