A kind of Fenton carrier of carbon-based solid acid and its preparation method and application

A carbon-based solid acid, carrier technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxidized water/sewage treatment, etc., can solve problems such as increasing treatment costs, secondary pollution, etc. Scope, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

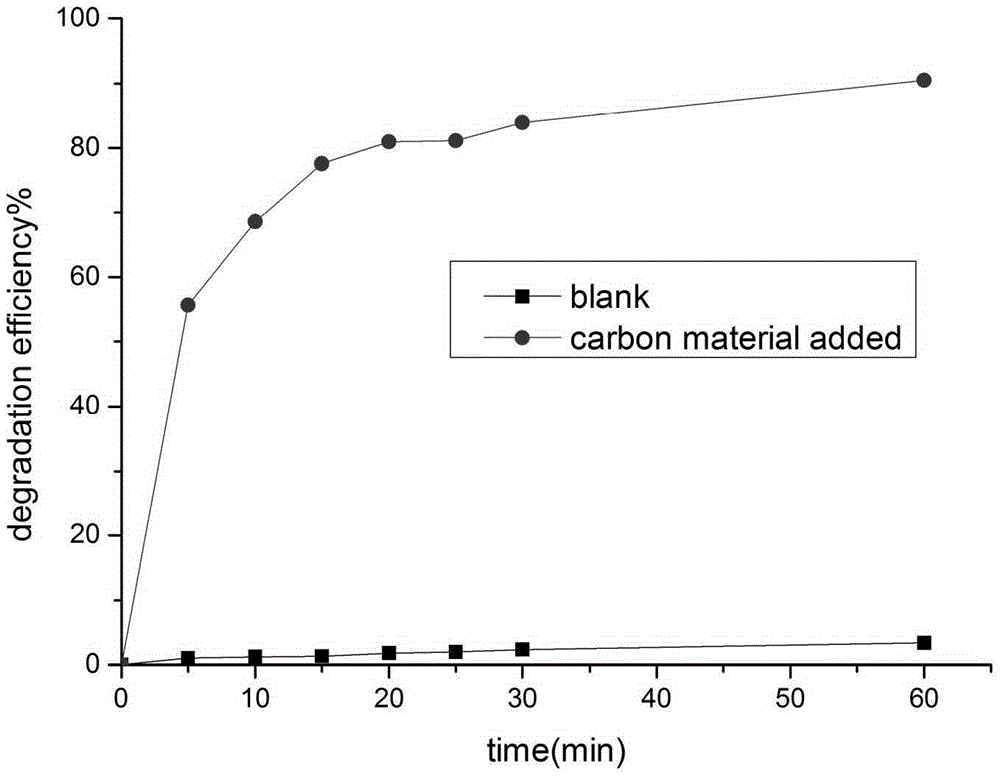

Embodiment 1

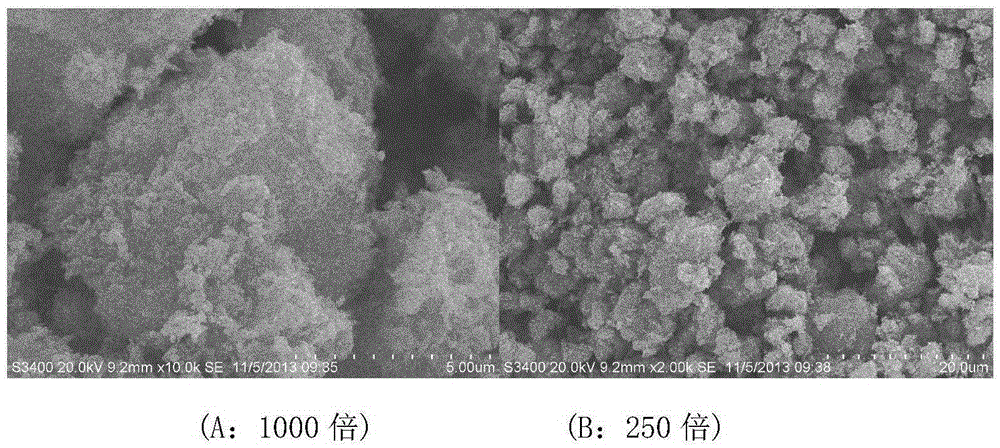

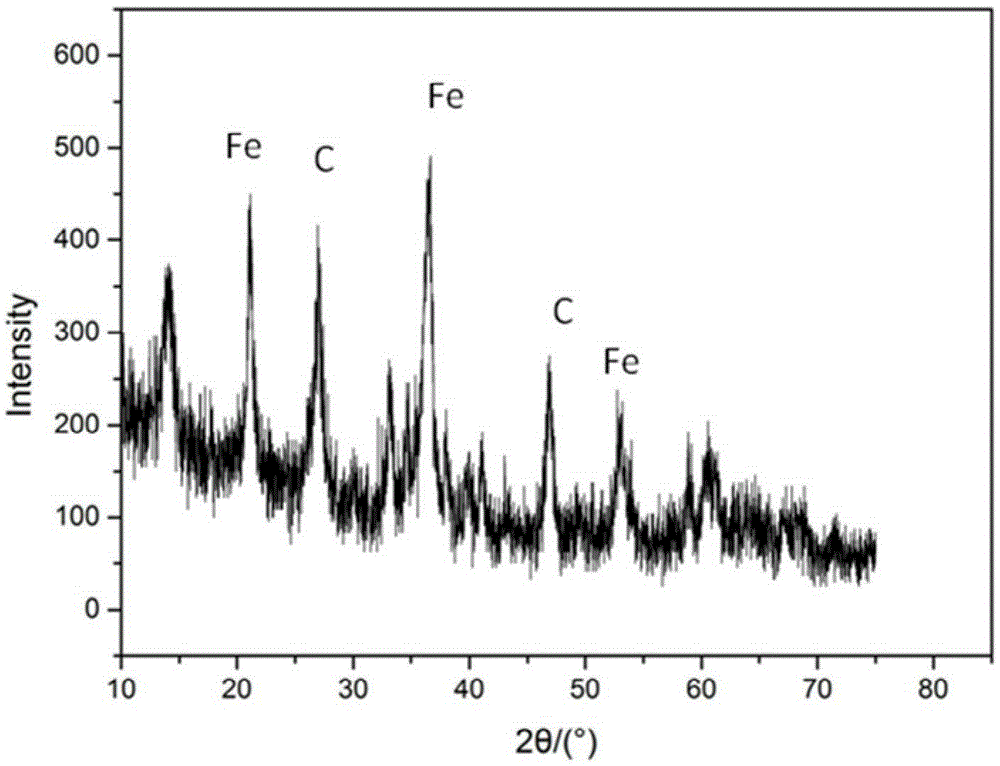

[0026] (1) Weigh 39.6g of D-glucose and dissolve it in 200ml of pure water to obtain an aqueous solution of glucose, which is placed in a high-temperature and high-pressure reactor. Place in a constant temperature box at 180°C for 15 hours, cool to room temperature, wash with deionized water and absolute ethanol three times, then store with absolute ethanol, and dry in a vacuum oven to obtain carbon materials.

[0027] (2) Add carbon material powder (about 30ml) into 300ml concentrated sulfuric acid, N 2 Stir the reaction in an oil bath at 150°C for 15 hours under atmospheric conditions. After cooling to room temperature, slowly add deionized water, let it stand for 20 minutes to precipitate, pour off the supernatant, and wash the precipitate repeatedly with deionized water higher than 80°C. until no SO was detected in the supernatant 4 2- Dry the precipitate and grind to obtain black sulfonated carbon material solid acid.

[0028] (3) Weigh 80.8 g of ferric nitrate and dis...

Embodiment 2

[0036] (1) Weigh 29.7g of D-glucose and dissolve it in 200ml of pure water to obtain an aqueous glucose solution, which is placed in a high-temperature and high-pressure reaction kettle. Place in a thermostat at 190°C for 15 hours, cool to room temperature, and then wash with deionized water and absolute ethanol for three times, then store in absolute ethanol, and dry in a vacuum oven to obtain carbon materials.

[0037] (2) Add carbon material powder (about 25ml) into 250ml concentrated sulfuric acid, N 2 Stir the reaction in an oil bath at 140°C for 15 hours under atmospheric conditions. After cooling to room temperature, slowly add deionized water, let it stand for 20 minutes to precipitate, pour off the supernatant, and wash the precipitate repeatedly with deionized water higher than 80°C. until no SO was detected in the supernatant 4 2- Dry the precipitate and grind to obtain black sulfonated carbon material solid acid.

[0038](3) Weigh 60.6 g of ferric nitrate and di...

Embodiment 3

[0043] (1) Weigh 35.6g of D-glucose and dissolve it in 100ml of pure water to obtain an aqueous solution of glucose, which is placed in a high-temperature and high-pressure reaction kettle. Placed in a constant temperature box at 170°C for 15 hours, cooled to room temperature, washed with deionized water and absolute ethanol three times, then stored with absolute ethanol, and dried in a vacuum oven to obtain carbon materials.

[0044] (2) Add carbon material powder (about 28ml) into 280ml concentrated sulfuric acid, N 2 Stir the reaction in an oil bath at 160°C for 15 hours under atmospheric conditions. After cooling to room temperature, slowly add deionized water, let it stand for 20 minutes to precipitate, pour off the supernatant, and wash the precipitate repeatedly with deionized water higher than 80°C. until no SO was detected in the supernatant 4 2- Dry the precipitate and grind to obtain black sulfonated carbon material solid acid.

[0045] (3) Weigh 88.9 g of ferric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com