Test method and test device for simulating stratum deformation caused by pipe jacking construction

A technology of test device and test method, applied in the field of rock and soil mechanics test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A test method for simulating formation deformation caused by pipe jacking construction, the steps are:

[0046] 1) Install the laterally flexible loading bag: open the lateral water injection valve 45 and the first exhaust valve 12 on the laterally flexible loading bag 1, start the laterally loading booster pump 9, and fill the laterally flexible loading bag 1 with water until The lateral flexible loading bag 1 is filled with water, stops the water injection, and closes the lateral water filling valve 45 and the first exhaust valve 12, and then the lateral flexible loading bag 1 is installed at the preset position on the right side wall of the model box 19.

[0047] 2) Filling and buried depth monitoring components: Fill the test soil 42 evenly in layers in the model box 19, and bury the earth pressure cell 20 and the displacement sensor 21 at the preset position, and the earth pressure cell 20 and the displacement sensor 21 are externally connected The data acquisition...

Embodiment 2

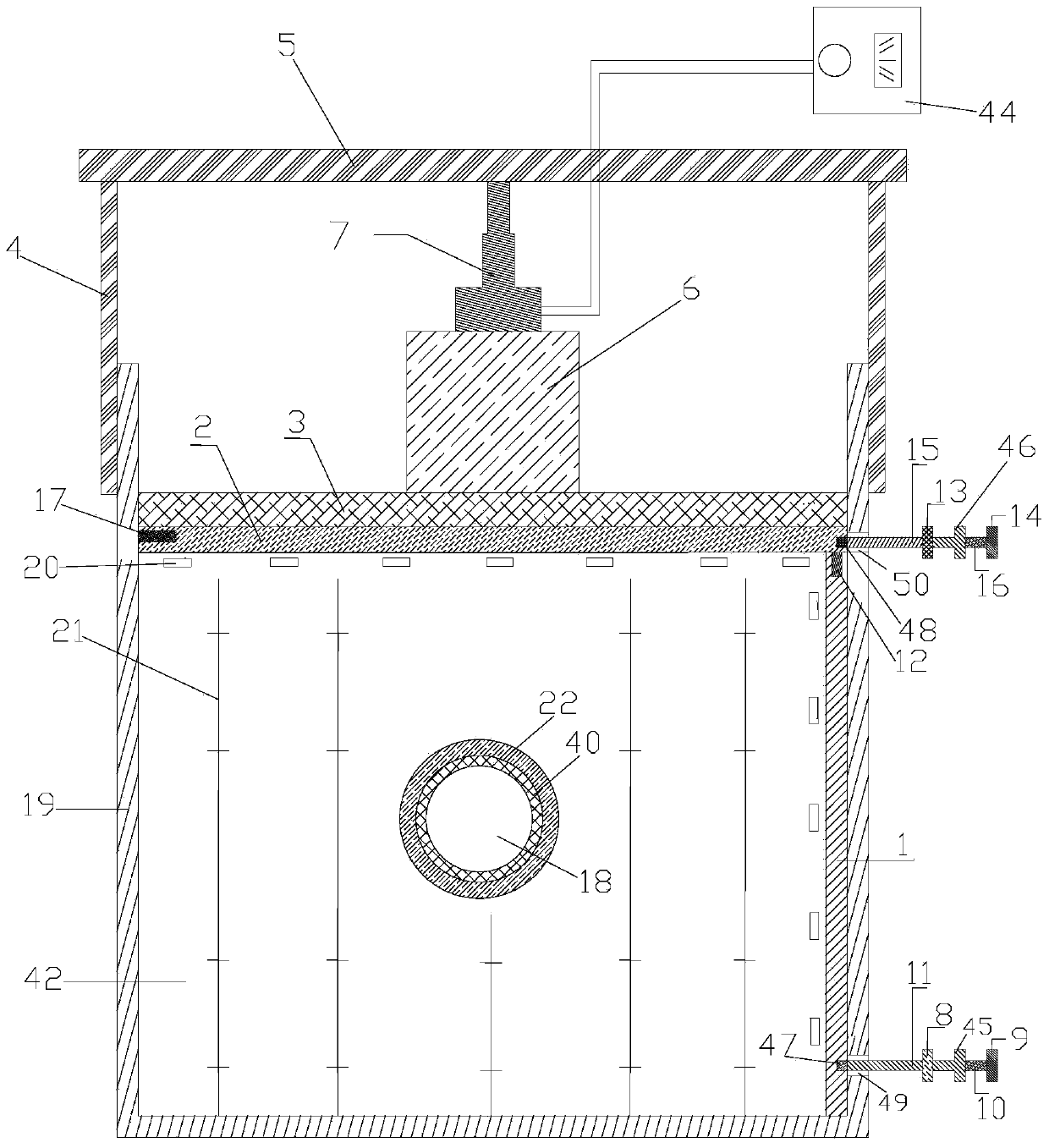

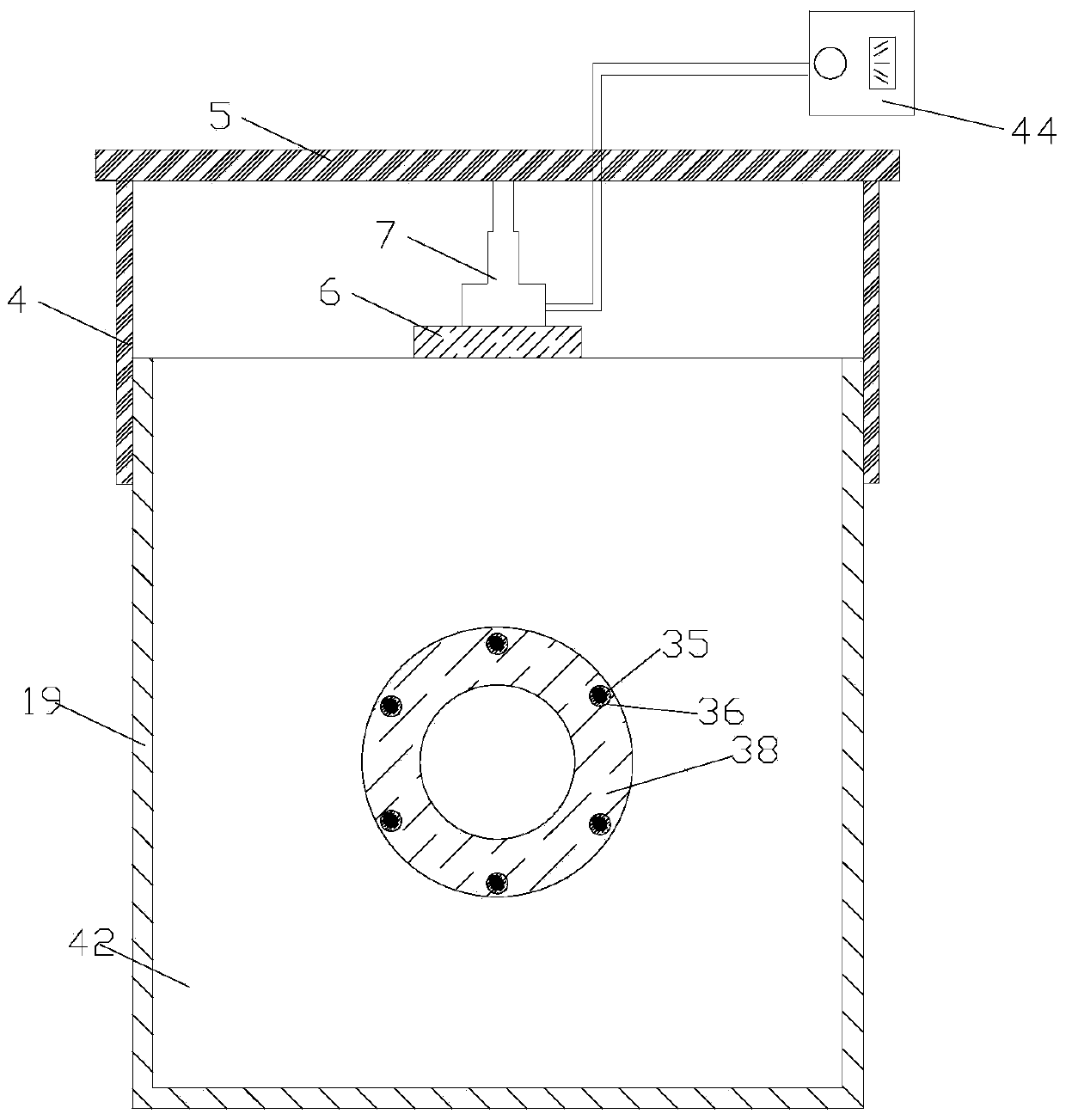

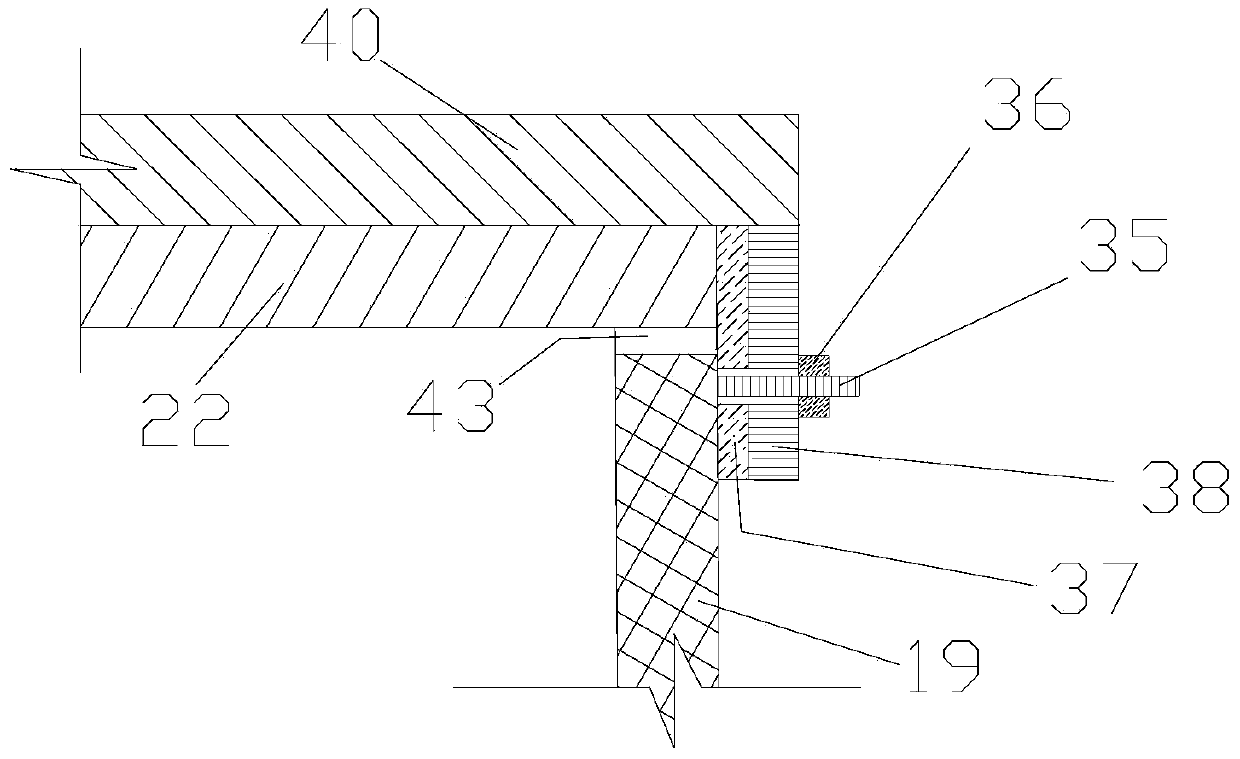

[0056] according to figure 1 , figure 2 , image 3 , Figure 4 It can be seen that a test device for simulating formation deformation caused by pipe jacking construction consists of lateral flexible loading bag 1, vertical flexible loading bag 2, rigid loading plate 3, reaction force frame column 4, reaction force frame beam 5, force transmission column 6. Hydraulic jack 7. Lateral loading pressure gauge 8. Lateral loading pressurization pump 9. First lateral pressurization water injection pipe 10. Second lateral pressurization water injection pipe 11. First exhaust valve 12. Vertical Loading pressure gauge 13, vertical loading pressurization pump 14, first vertical pressurized water injection pipe 15, second vertical pressurized water injection pipe 16, second exhaust valve 17, simulated pipe jacking 18, model box 19, soil Pressure box 20, displacement sensor 21, annular water bag 22, water inlet main pipe 23, water inlet main pipe pressure gauge 24, water inlet main pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com