Electric equipment fault forecasting method based on multi-dimension time sequence

A technology of time series and equipment failure, which is applied in the interdisciplinary research field of computer technology and electric power, and can solve problems such as single, difficult failure, impact prediction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

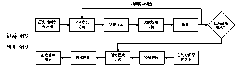

[0046] This method is mainly divided into two stages: the training stage and the prediction stage. image 3 shown.

[0047] The first stage is the training stage, which includes historical time series data decomposition, feature generation, and association rule analysis. The measurement module is to judge the credibility of the results of association rule analysis. If the support and confidence of the generated prediction rules meet the requirements , these rules are stored in the rule base for use in the prediction stage; otherwise, the time window parameters and participating computing device nodes are adjusted to perform iterative calculations until the results meet the requirements. Through the above steps of the training process, a prediction rule with a certain degree of reliability is established.

[0048] The second stage is the prediction stage. In the application of equipment failure prediction, it is necessary to collect the online monitoring data of each node in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com