Method for testing failure of airplane antiskid brake control box under condition of temperature cycle

A technology of anti-skid brakes and temperature cycling, applied in electrical testing/monitoring, etc., can solve the problems of incomplete screening of defects, unsatisfactory excitation, and incomplete screening of faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

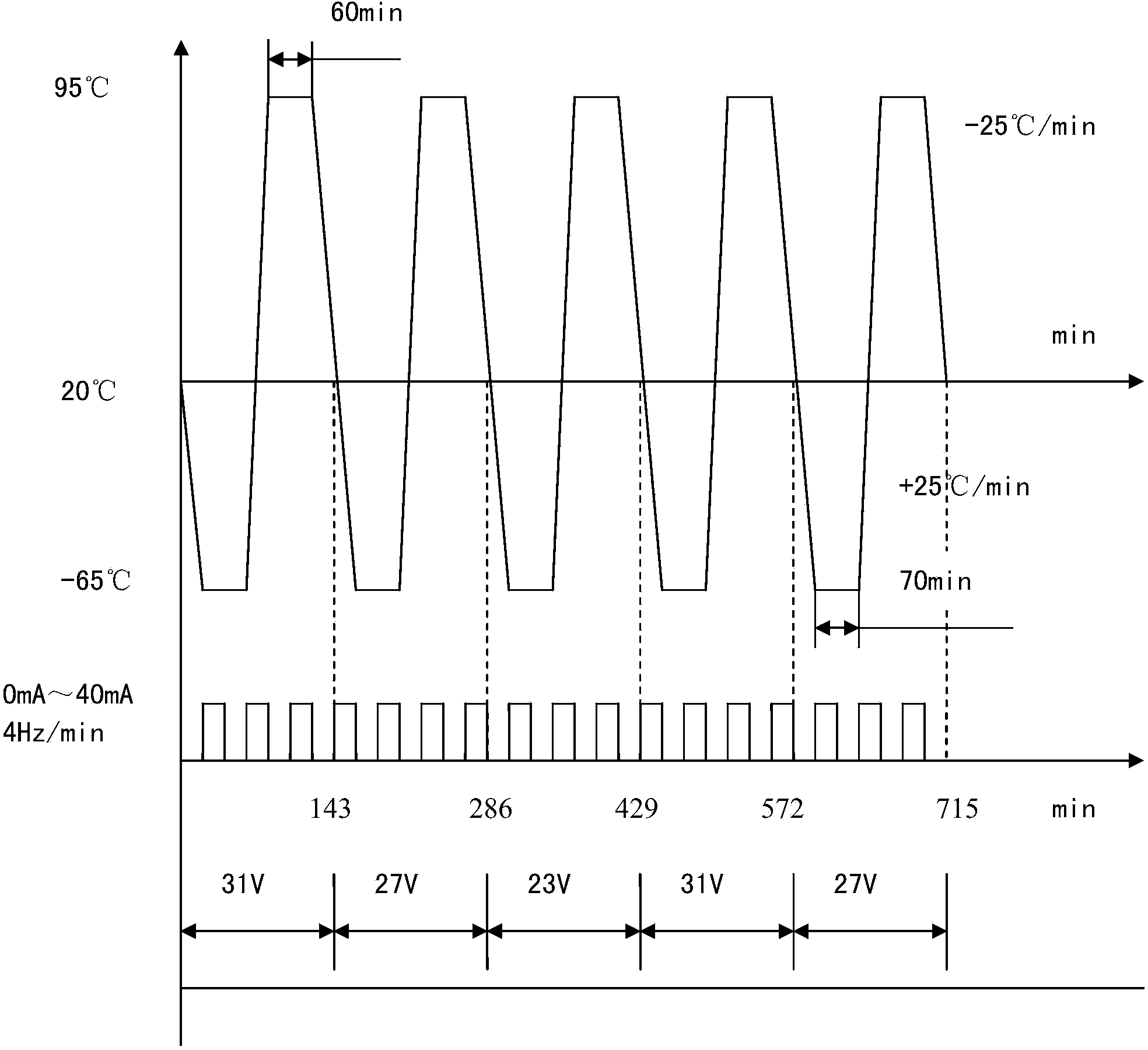

Embodiment 1

[0086] This embodiment is a performance test of an anti-skid brake control box of a transporter under temperature cycle conditions.

[0087] Implementation steps:

[0088] Step 1. Determine the high temperature value of the antiskid brake control box temperature cycle

[0089] The high-temperature working limit of the anti-skid brake control box was tested by using the method of applying high-temperature step stress to the anti-skid brake control box disclosed in the invention of Patent No. 201110310885.1. The antiskid brake control box described in this embodiment is improved to achieve a high temperature working limit of 100°C;

[0090] Determine the high temperature value of the temperature change in the reliability strengthening test chamber. The high temperature value of the temperature cycle is 5°C lower than the high temperature working limit. The high temperature value in this embodiment is 95°C, and 95°C is used as the high temperature value for formulating the tempe...

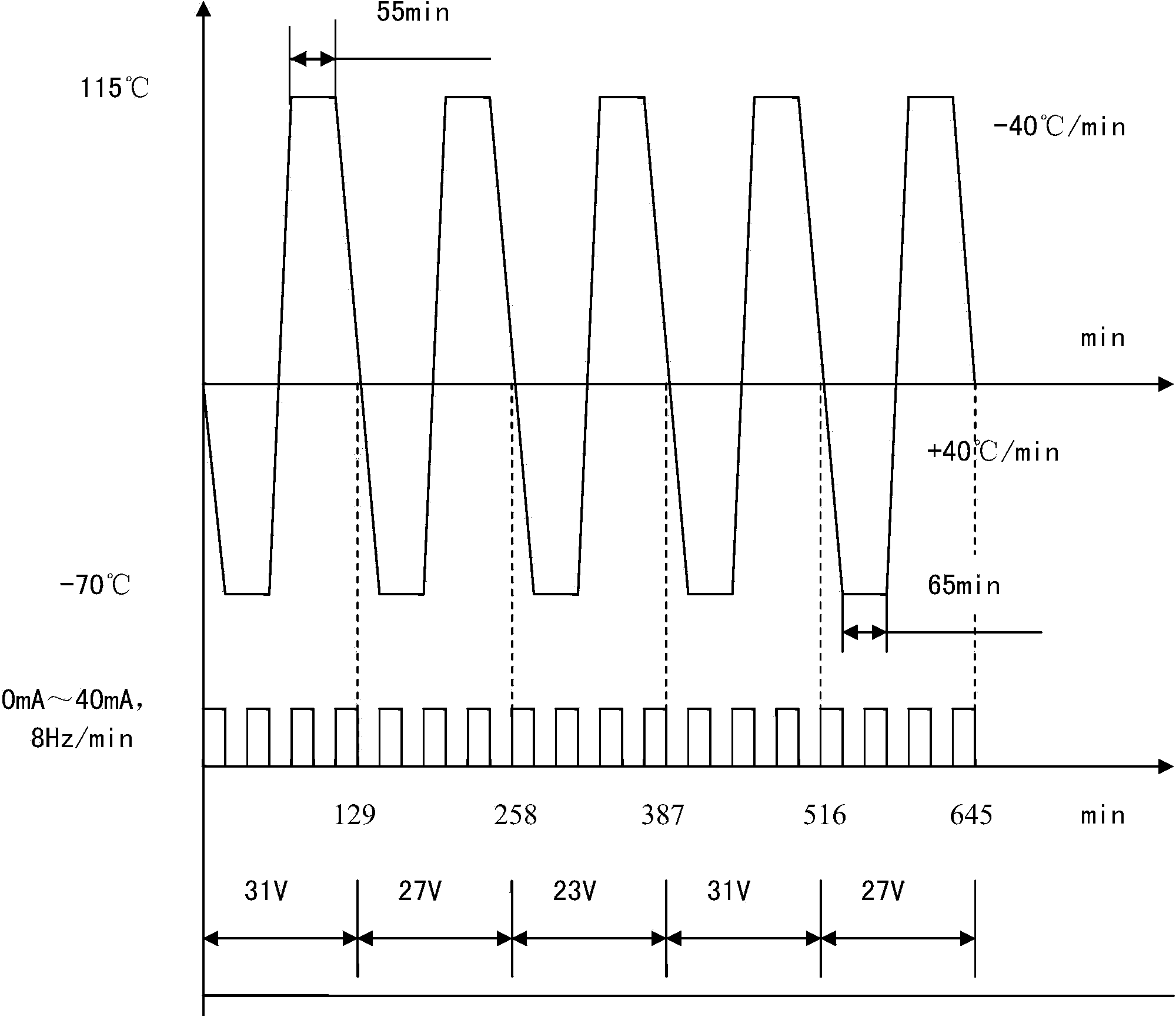

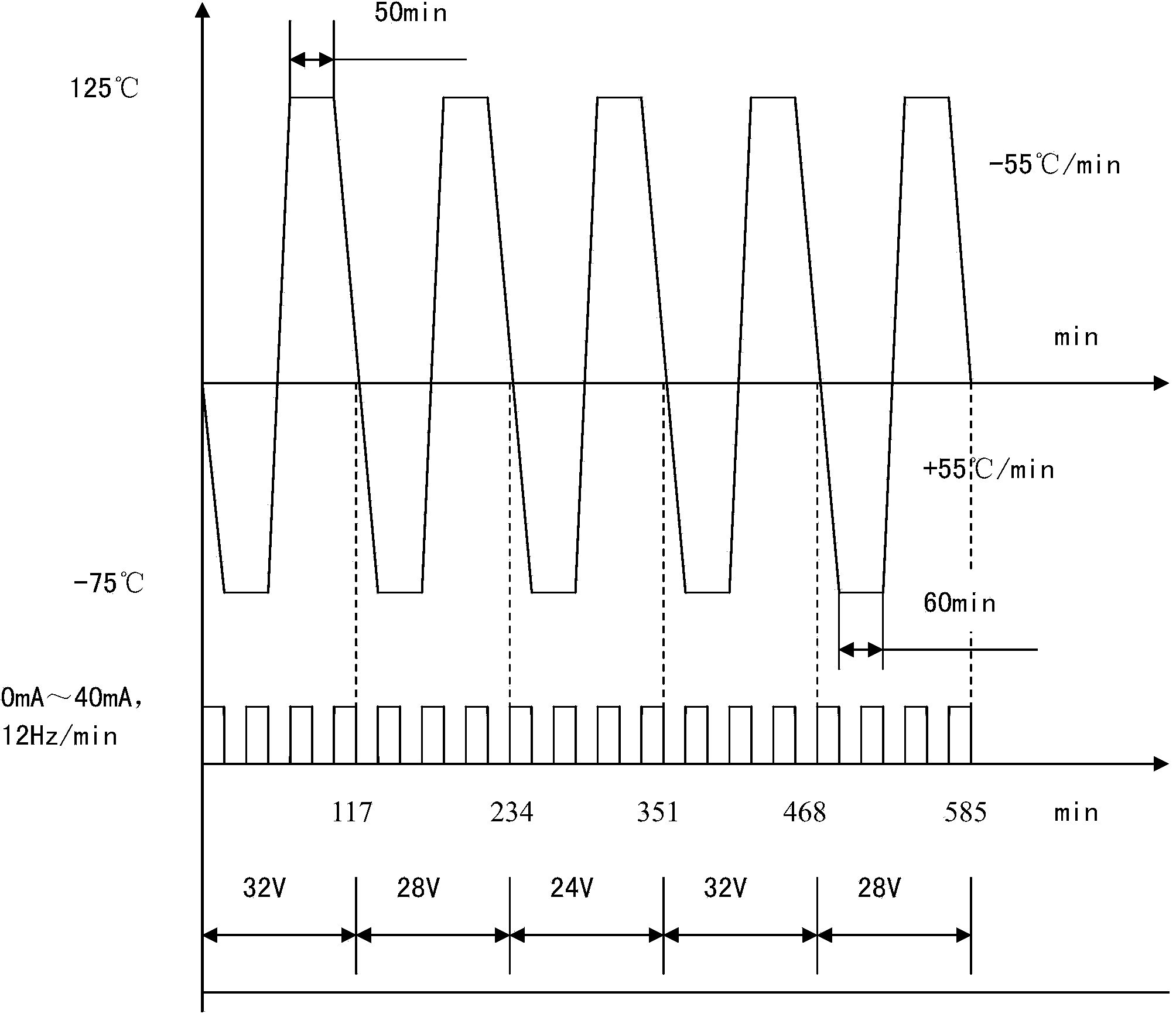

Embodiment 2

[0128] Both embodiment 2 and embodiment 3 include determining the high temperature value of the antiskid brake control box temperature cycle, determining the low temperature value of the antiskid brake control box temperature cycle, determining the rising rate and falling rate of the temperature in the test chamber, and determining the output of the antiskid brake control box. working current, determine the output duration of the working current of the anti-skid brake control box, determine the duration after the anti-skid brake control box reaches the highest temperature and the lowest temperature, determine the number of temperature cycles, and carry out the test steps according to the requirements of the temperature cycle test. The specific process is the same as The process of Example 1 is the same.

[0129] The difference between Example 1 and Example 2 and Example 3 lies in that the test data in Example 2 and Example 3 are different from the test data in Example 1, as sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com