Automatic feeder matching electrical testing equipment

A technology of automatic feeding and electric testing machine, which is applied to typewriters, conveyor objects, printing, etc., can solve the problems of high labor intensity for workers, inconvenient jigsaw templates, and affecting the production of the whole line, so as to achieve simple and reasonable structure and shorten the operation time. Turnover cycle, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

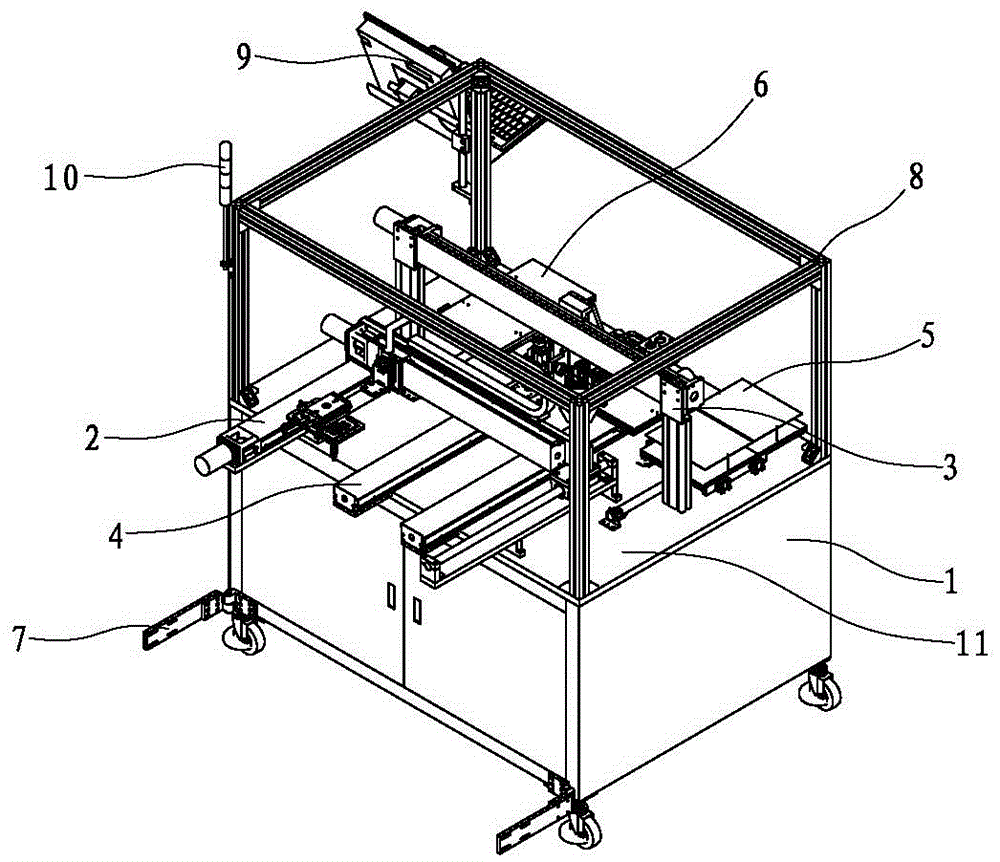

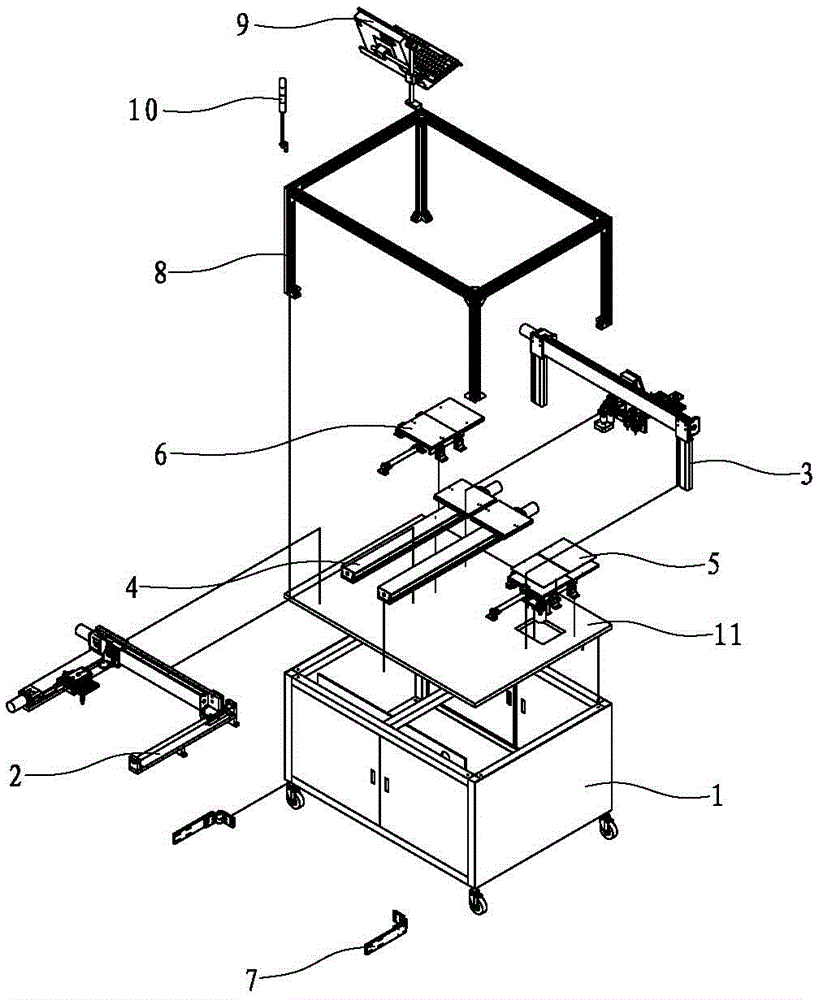

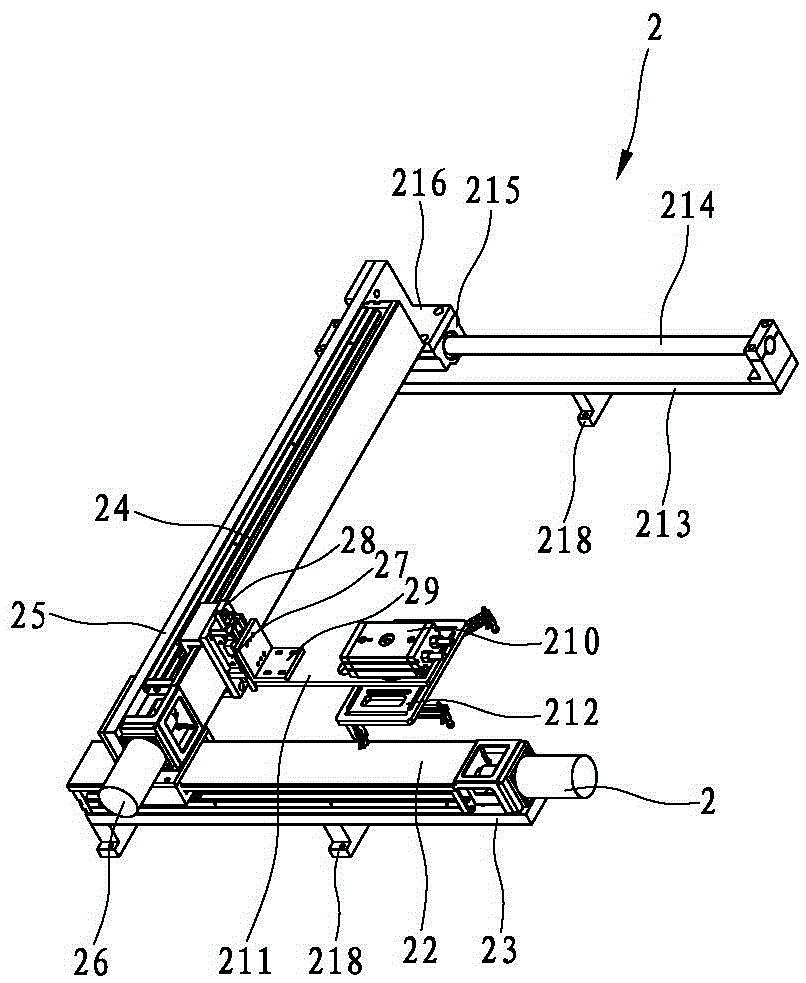

[0023] Such as figure 1 , figure 2 As shown, the present invention is an automatic feeder for matching electrical measuring equipment, which includes a frame 1, a feeding manipulator 2, a handling marking manipulator 3, two groups of forward and backward moving mechanisms 4, a jacking-up feeding mechanism 5, A double-station mobile blanking mechanism 6, two sets of hinged quick positioning mechanisms 7, a dust-proof frame 8, an industrial computer 9, and a signal light frame 10.

[0024] The feeding manipulator 2, the handling marking manipulator 3, the two groups of forward and backward moving mechanisms 4, the jacking-up feeding mechanism 5, and the double-station moving and unloading mechanism 6 are all installed on the working table 11 of the frame 1, and according to the working order , the discharge position of the jacking-up feeding mechanism 5 is connected with the feed position of the transport marking manipulator 3, the discharge position of the transport marking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com