Automatic electric detecting machine

An electric testing machine and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of missed testing, false testing of unqualified products, inconvenient jigsaw templates, and affecting the production of the whole line, etc., to achieve stable operation Reliable, simple and reasonable structure, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

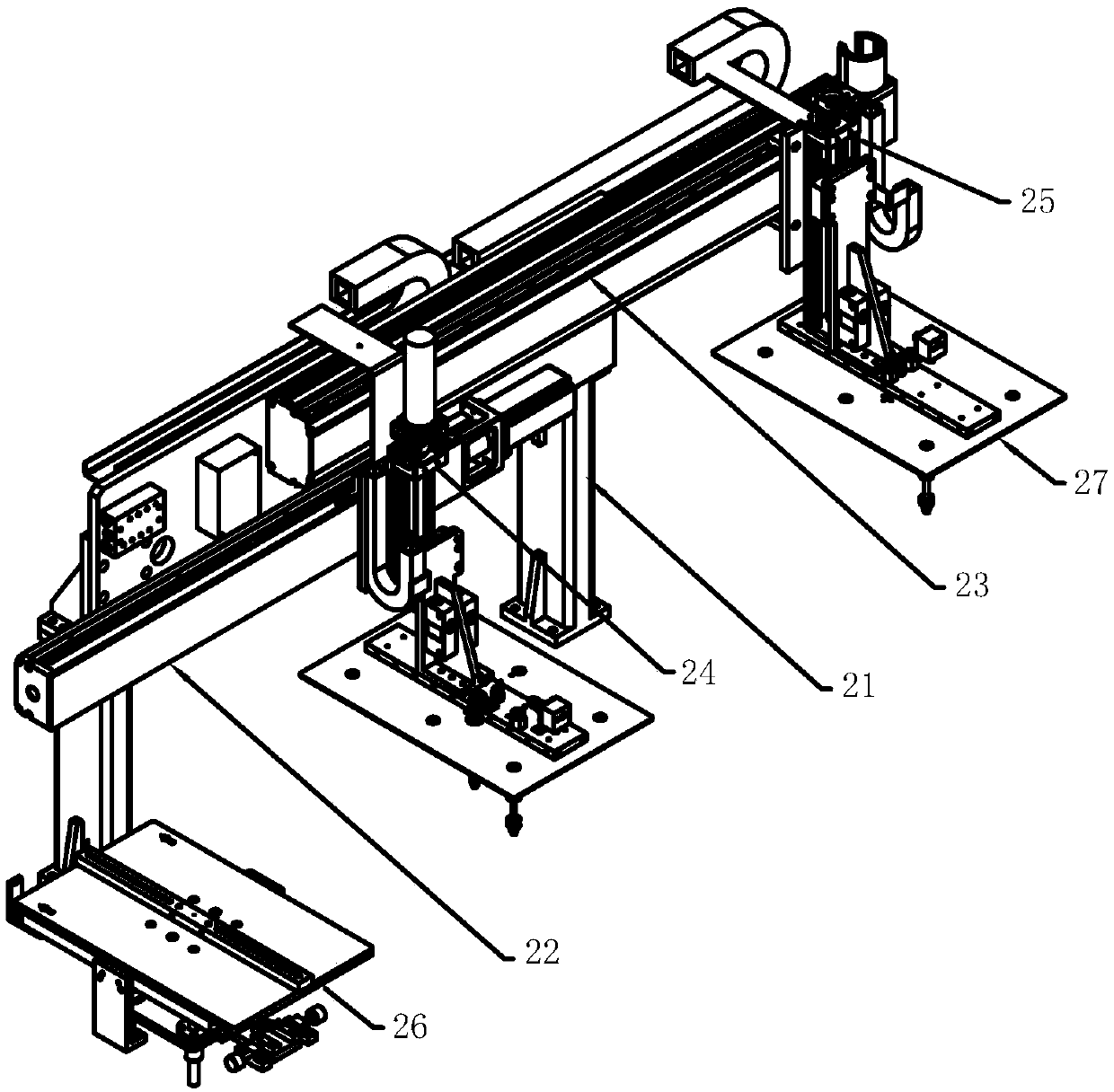

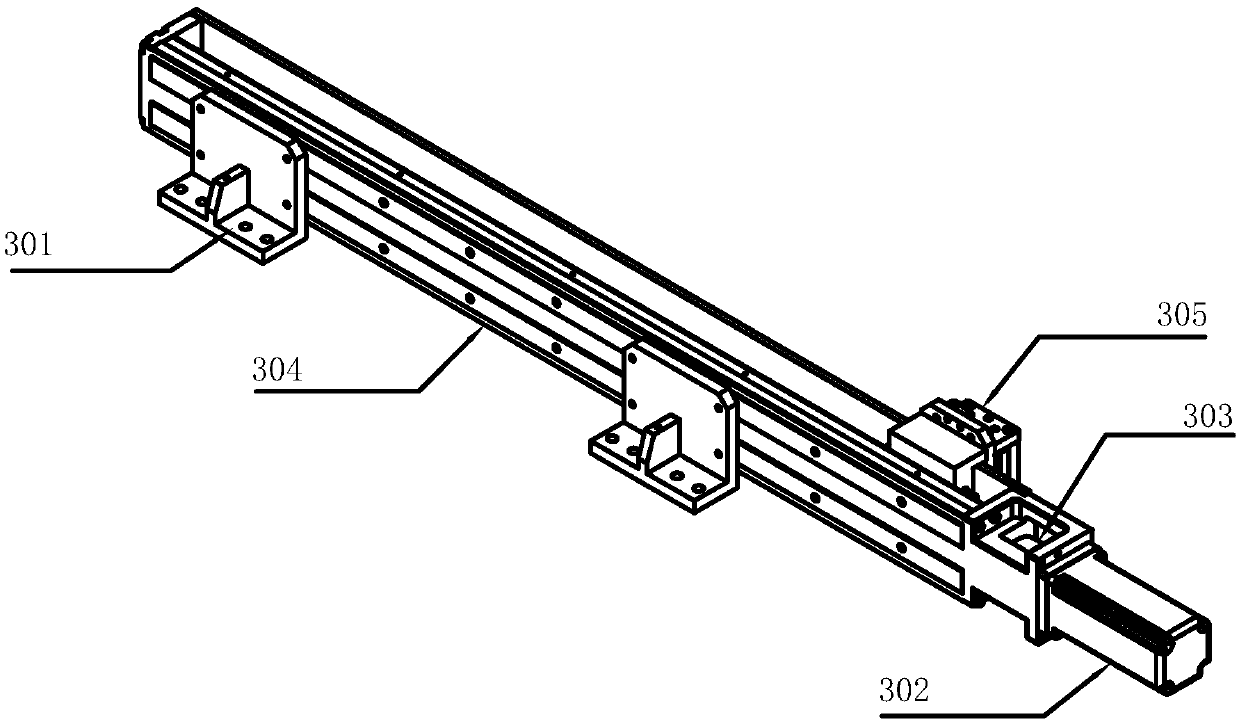

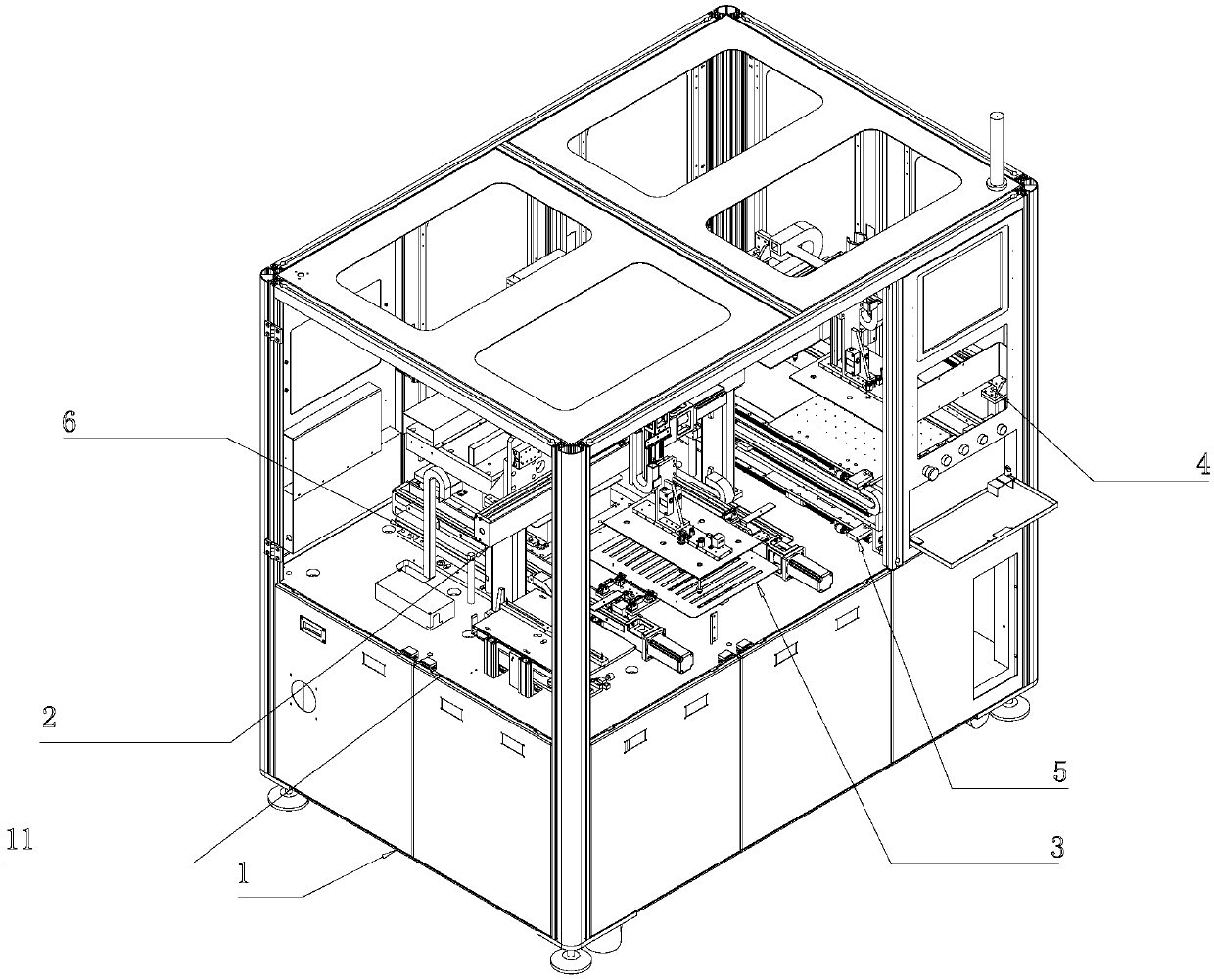

[0052] refer to figure 1 , an automatic electric measuring machine, comprising a frame 1, a working platform 11 is arranged in the said frame 1, and said working platform 11 is provided with a loading and unloading conveying mechanism 2, a feeding and conveying mechanism 3, a marking mechanism 4, a lower A material mechanism 5; the loading and unloading conveying mechanism 2 is distributed with loading and unloading grabbing components;

[0053] The general working process of the above-mentioned automatic electrical testing machine is: the feeding and grabbing parts grab the product to be tested and send it to the feeding station of the feeding and transporting mechanism 3; the product to be tested moves to the testing station along with the feeding station. After the product to be tested is detected by the electric measuring machine, the detection sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com