Warp and weft hyperbolic weaving method of woven fabric and fabricated fabric

A woven fabric, hyperbolic technology, applied in the direction of fabrics, textiles, papermaking, textiles, etc., can solve the problem of a single variety of woven fabrics, and achieve the effect of changing the density of warp and weft and improving the grade of varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

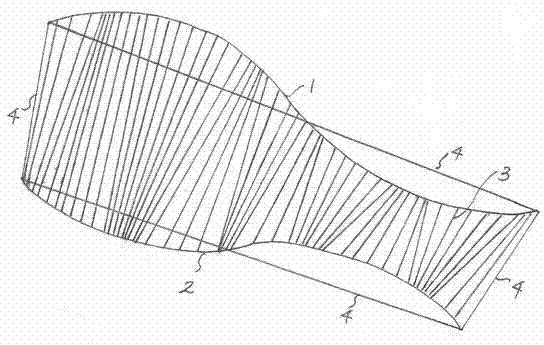

[0012] A hyperbolic weaving method for warp and weft yarns of woven fabrics, which adopts a double-curved three-dimensional curved surface dense-density reed, and the double-curved three-dimensional curved surface dense-density reed includes a rectangular positioning bracket 4 for positioning, and the upper and lower ends of the positioning bracket are set respectively. , lower side 1, 2, the upper and lower sides are "S" shape, and when the upper side 1 is a sine wave, the corresponding lower side 2 is a negative 180° sine wave, and when the upper side is a negative 180° sine wave, the corresponding lower side is 180 °Sinusoidal waveform, the upper and lower sides are connected up and down by steel wire 3 to form a three-dimensional curved reed surface. Just sparse; when the fabric is beating up, move the double-curved three-dimensional surface dense-density reed up and down; when the double-curved three-dimensional surface dense-density reed beats up wefts during the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com