Woven fabric weft curve fabric and weaving method

A technology of weft curves and woven fabrics, applied in fabrics, textiles, papermaking, textiles, etc., can solve the problem of single color of woven fabrics, improve the variety grade, and achieve the effect of changing the weft density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

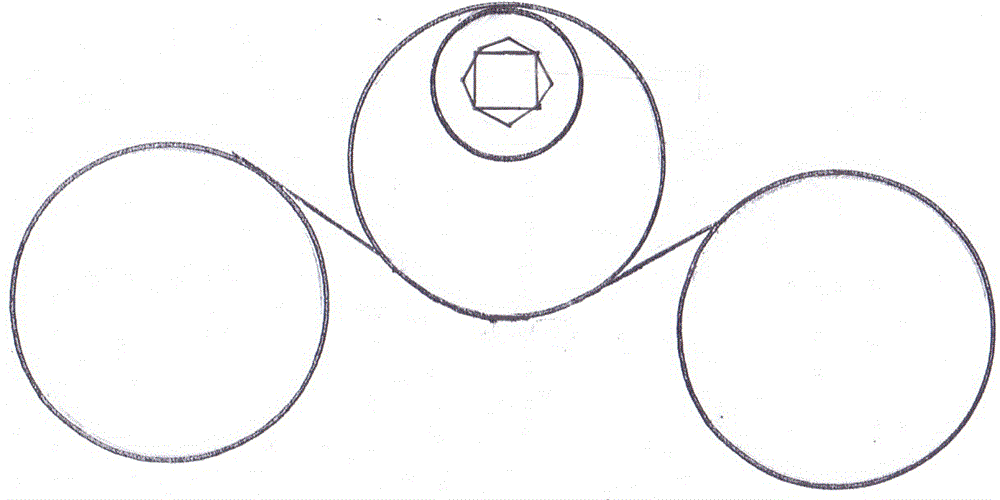

Image

Examples

Embodiment 1

[0016] A method for weaving weaving curves of weft yarns of woven fabrics, using a device capable of controlling the warp let-off of some warp yarns, and changing the weft density by changing the warp let-off, so that the weft yarns are bent and deformed, showing a curved effect on the cloth surface ;

[0017] The device capable of controlling the let-off amount of part of the warp yarns is composed of three rollers in the shape of a character, wherein the lower two are tension rollers with smooth surfaces, and the upper one is a cam roller for adjusting the warp let-off tension; Supporting, the tension-adjusting and deformed cam roller of the upward feeding warp acts on the warp yarn according to the surface contour curve. Reduce the let-off effect, and the weft density at this time becomes larger; when the upper let-off tension is adjusted and the deformed cam roller operates from the cam tip contour curve to the cam base circle contour curve to the warp yarn, it plays the r...

Embodiment 2

[0024] A method for weaving weaving curves of weft yarns of woven fabrics, using a device capable of controlling the warp let-off of some warp yarns, and changing the weft density by changing the warp let-off, so that the weft yarns are bent and deformed, showing a curved effect on the cloth surface ;

[0025] The device capable of controlling the let-off amount of part of the warp yarns is composed of three rollers in the shape of a character, wherein the lower two are tension rollers with smooth surfaces, and the upper one is a cam roller for adjusting the warp let-off tension; Supporting, the tension-adjusting and deformed cam roller of the upward feeding warp acts on the warp yarn according to the surface contour curve. Reduce the let-off effect, and the weft density at this time becomes larger; when the upper let-off tension is adjusted and the deformed cam roller operates from the cam tip contour curve to the cam base circle contour curve to the warp yarn, it plays the r...

Embodiment 3

[0032] A method for weaving weaving curves of weft yarns of woven fabrics, using a device capable of controlling the warp let-off of some warp yarns, and changing the weft density by changing the warp let-off, so that the weft yarns are bent and deformed, showing a curved effect on the cloth surface ;

[0033] The device capable of controlling the let-off amount of part of the warp yarns is composed of three rollers in the shape of a character, wherein the lower two are tension rollers with smooth surfaces, and the upper one is a cam roller for adjusting the warp let-off tension; Supporting, the tension-adjusting and deformed cam roller of the upward feeding warp acts on the warp yarn according to the surface contour curve. Reduce the let-off effect, and the weft density at this time becomes larger; when the upper let-off tension is adjusted and the deformed cam roller operates from the cam tip contour curve to the cam base circle contour curve to the warp yarn, it plays the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com