Method of compensating for adapters or extensions on an electronic torque wrench

An adapter, torque sensor technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of damaged fasteners and related components, time-consuming, incorrect final torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can have many embodiments in different forms; here, one embodiment of the present invention will be described in detail with the drawings. It should be understood that this disclosure should be considered as an illustration of the principles of the invention and not as a limitation of the invention in its broad aspects to the embodiments shown.

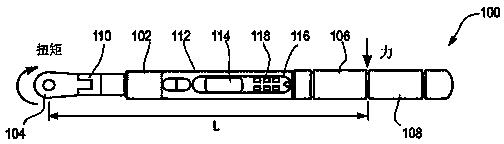

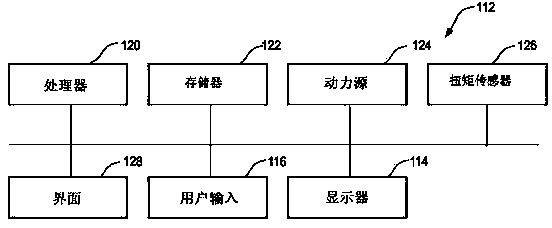

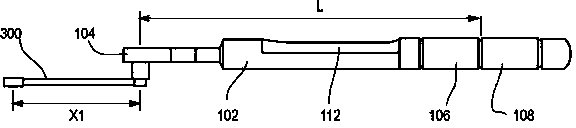

[0024] The present application discloses electronic torque tools that allow a user to adjust a torque length, also referred to herein as an offset length, to compensate for an adapter or extension connected to the tool. When the tool head of the tool is replaceable, the tool may also comprise input means for inputting the head length. The tool may also include an input device for entering a specific code for the adapter, extension, or replaceable tool head, wherein the tool may use a search list to automatically determine the offset length. In one embodiment, the code may be imprinted on the extension, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com