High-altitude propeller and propeller tip winglet capable of improving efficiency of high-altitude propeller

A technology of efficiency and blades, applied in propellers, aircraft parts, transportation and packaging, etc., can solve the problems of increasing propeller energy loss, reducing the effective angle of attack of each blade position, and reducing propeller efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

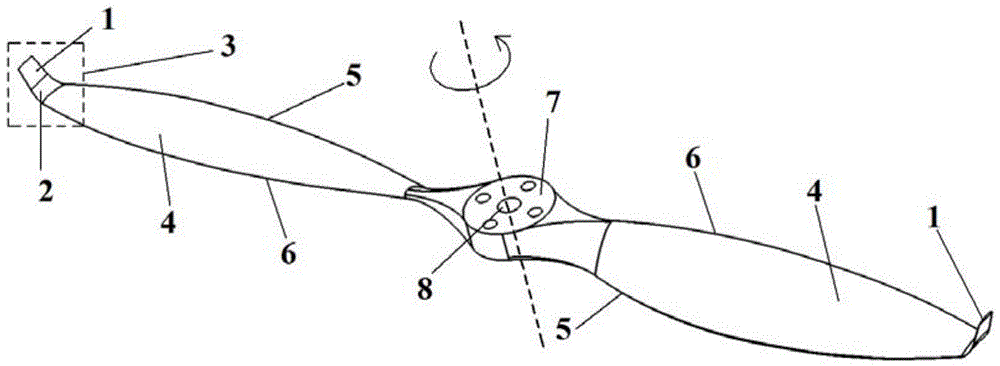

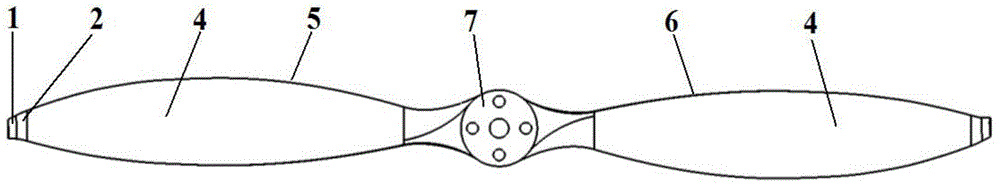

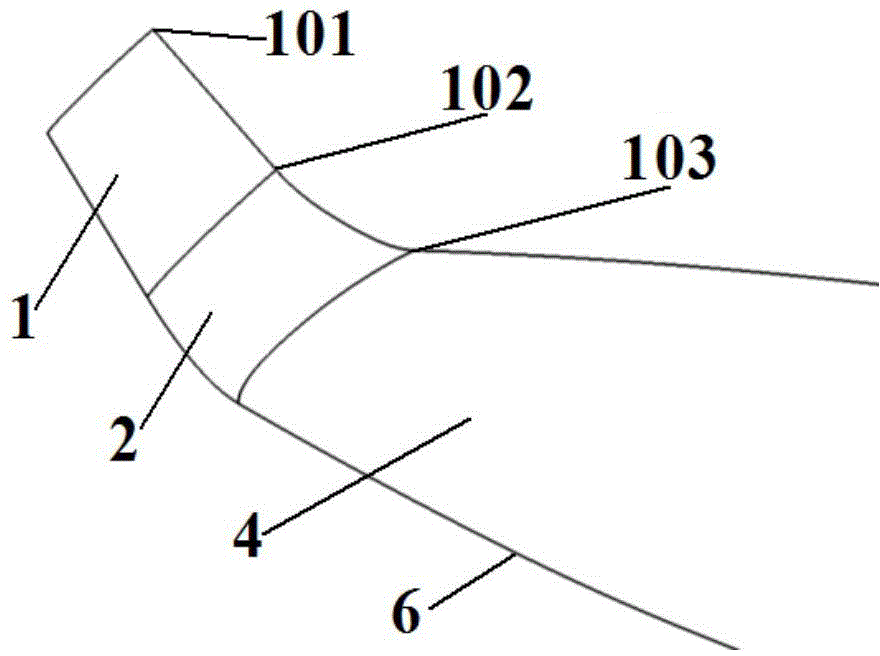

[0031] The present invention provides a blade tip winglet and a high-altitude propeller with improved high-altitude propeller efficiency, wherein the high-altitude propeller is a propeller suitable for a working height of 15-20 km, such as figure 1 with figure 2 As shown, the high-altitude paddle is made up of three parts, the paddle hub 7, the basic blade and the paddle-tip winglet. Wherein, 4 represents the upper surface of the basic blade, 5 represents the trailing edge of the basic blade, 6 represents the leading edge of the basic blade, and 9 represents the lower surface of the basic blade. The propeller hub 7 is provided with a propeller mounting hole 8 . The paddle-tip winglet is in the form of an upturned winglet, which is composed of a winglet straight plate section 1 and a winglet transition section 2 .

[0032] Since the geometric structure parameters of the pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com