Electronic component mounting device and electronic component mounting method

A technology for electronic component installation and electronic components, applied in the direction of electrical components, electrical components, etc., can solve problems such as difficulty in ensuring component supply, sprocket position maintenance, and inability to guarantee the stop position accuracy of the carrier tape, etc., to achieve the effect of ensuring the stop position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

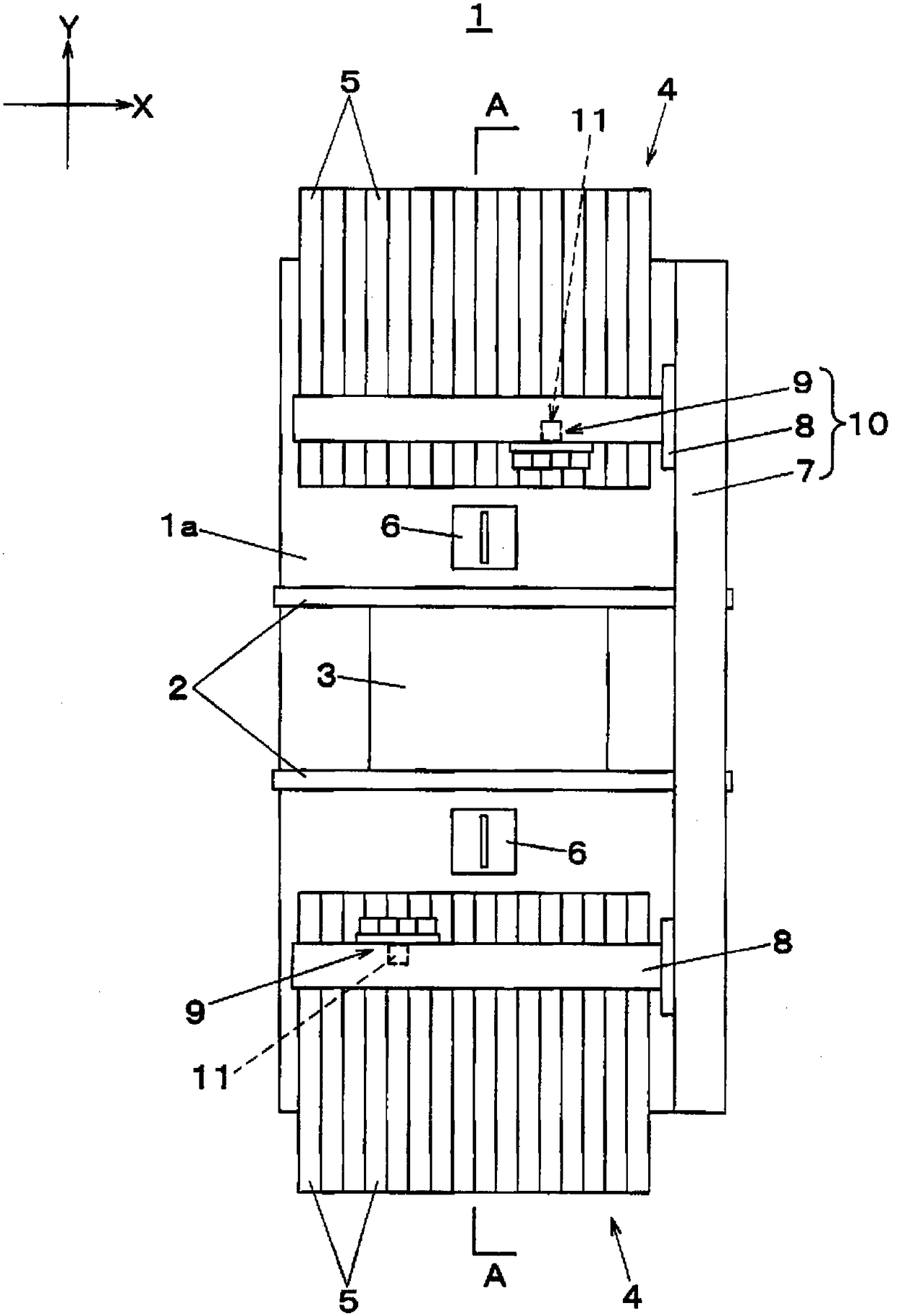

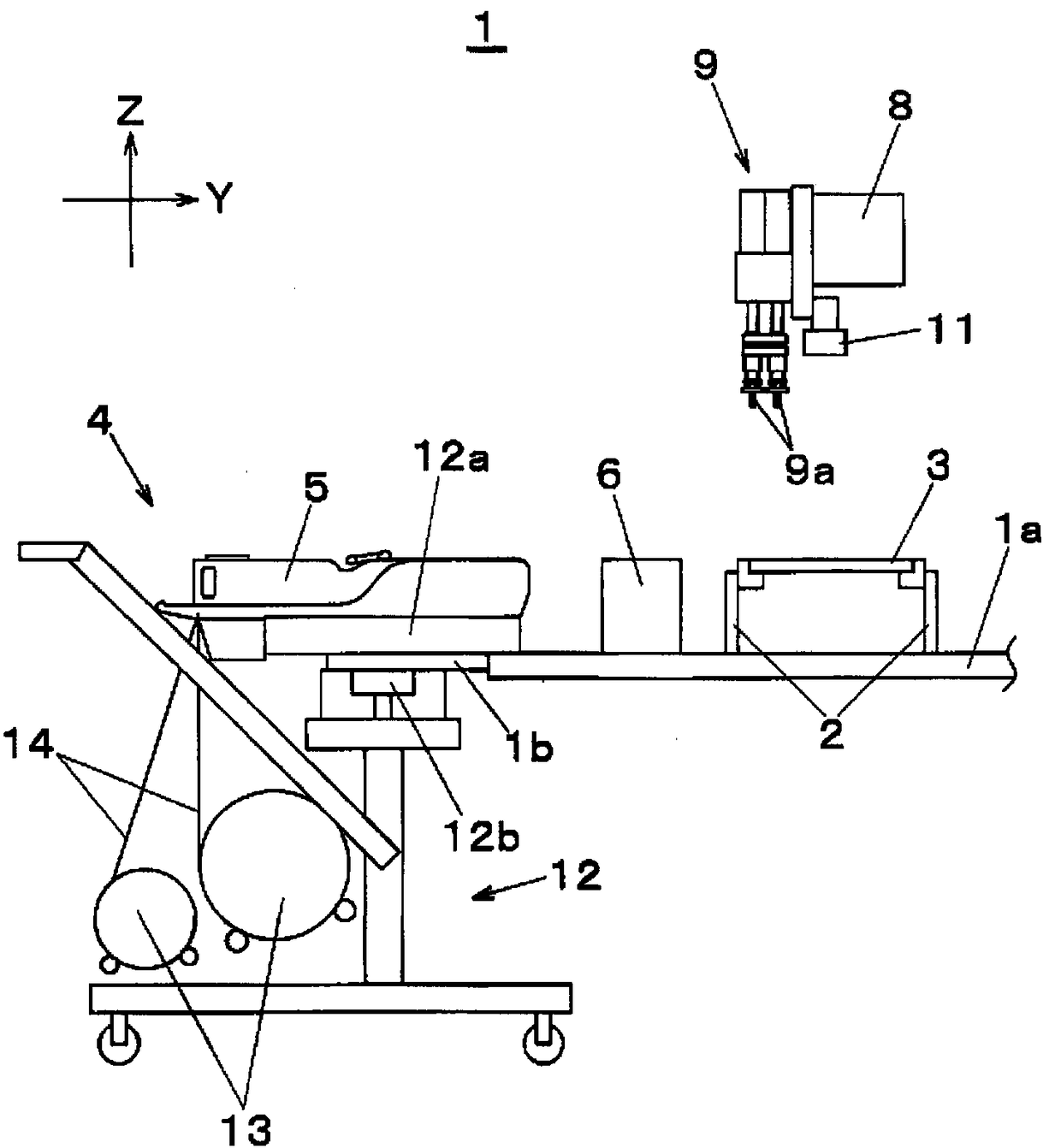

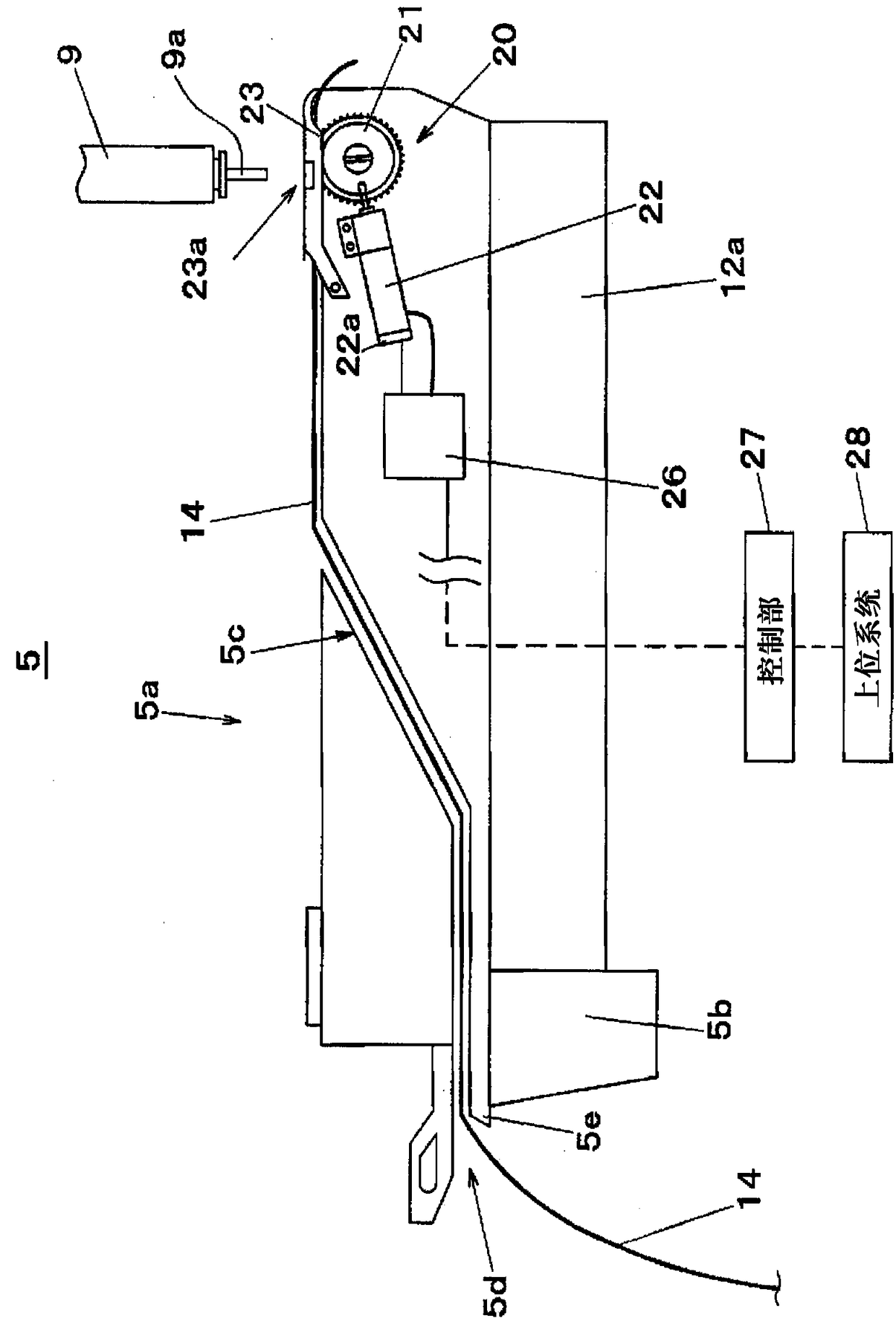

[0032] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , figure 2 The configuration of the electronic component mounting apparatus 1 for mounting electronic components on a substrate will be described. The electronic component mounting device 1 is used in a component mounting line for producing a mounting substrate, and has a function of mounting electronic components such as semiconductor chips on the substrate, figure 2 locally expressed figure 1 A-A profile in .

[0033] figure 1 Among them, the substrate transfer mechanism 2 is arranged along the X direction (substrate transfer direction) at the center of the base 1a. The substrate transport mechanism 2 transports the substrate 3 carried in from the upstream side, and positions and holds the substrate 3 on a mounting table set for performing component mounting work. Component supply units 4 are arranged on both sides of the board transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com