Electrified railway power grid system without negative sequence or spaced power supply networks in whole process

A technology for electrified railways and power supply systems, applied in power lines, railway vehicles, battery/battery traction, etc., can solve complex problems, and achieve the effects of increasing mechanical smoothness, simplifying complexity, and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

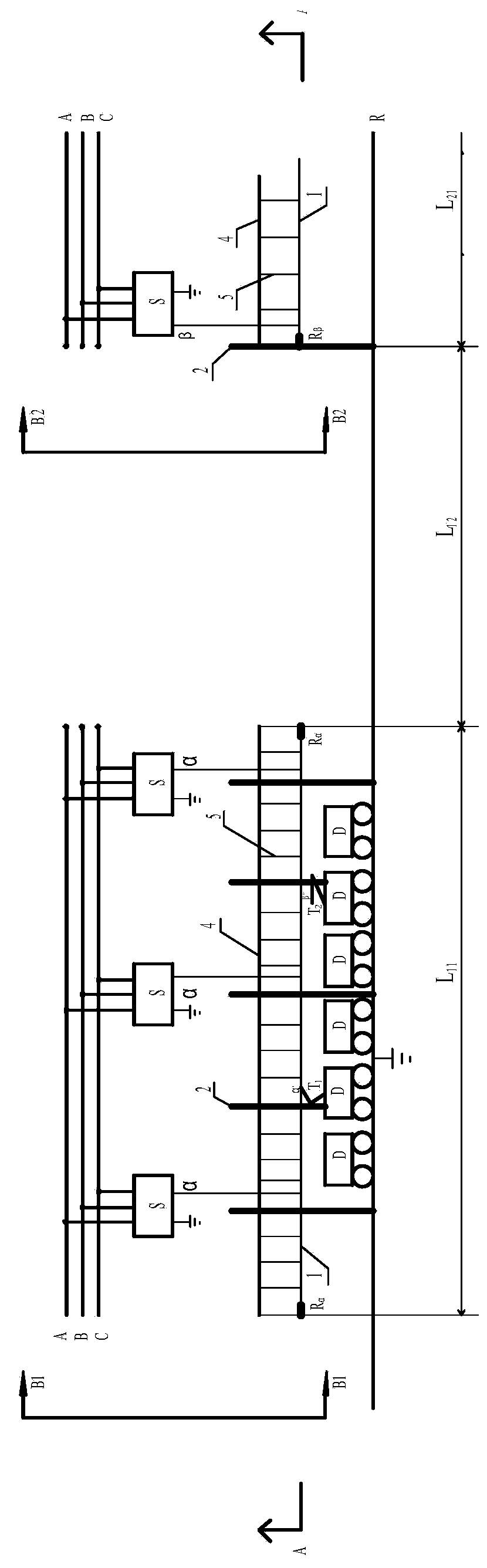

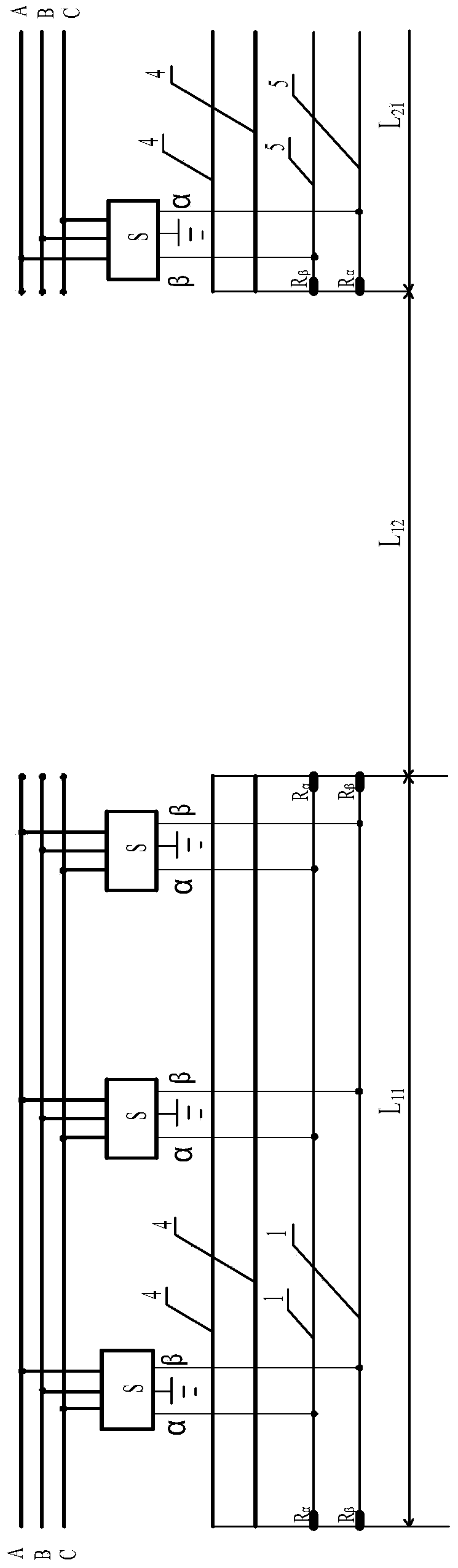

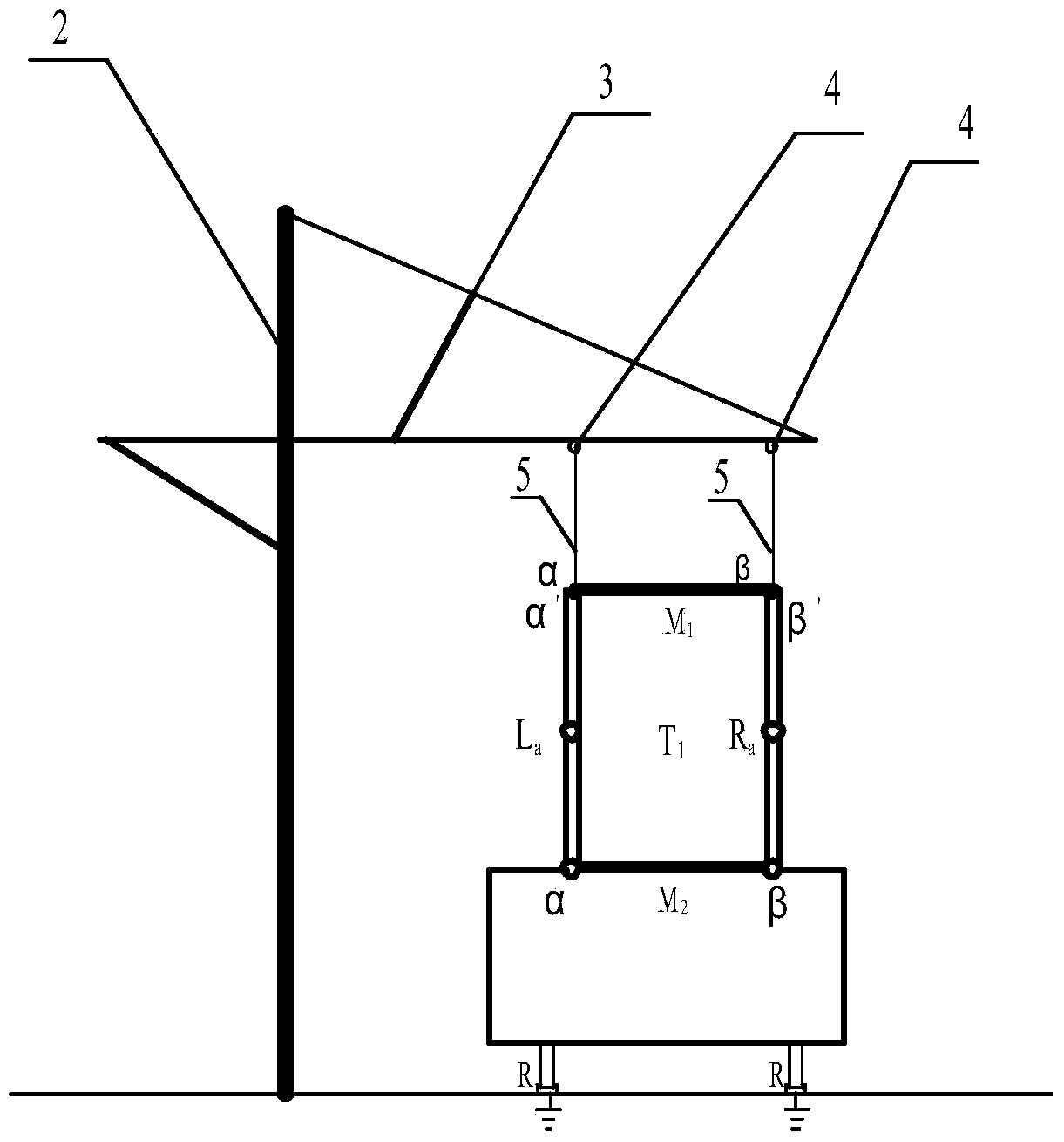

[0038] Such as figure 1 as shown, figure 1 The front view of the external power supply for the line, including the anchor pillar, the upper part of the anchor pillar is fixed with a wrist arm, and two parallel catenary cables are fixed on the wrist arm. The distance between the catenary cables is 1.94m. The suspension strings are set between the load-bearing cables and the contact wires. The upper ends of the two parallel suspension strings are connected to the two load-bearing cables, the lower ends of the two suspension strings are connected to the two contact wires, and the two parallel contact wires are connected to the traction transformer. The two single-phase α and single-phase β power lines output by the secondary side of S are connected. There are two roads on the up and down of the railway, such as figure 1 As shown in the symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com