Multistage circular blower for hollow polyphenylene sulfide short fibers

A polyphenylene sulfide and ring blower technology is applied in the field of chemical fiber manufacturing, which can solve the problems of wire strands dry deformation, poor molecular fluidity, molecular stress changes, etc., so as to reduce the loss of enterprises, improve the hollowing effect and improve the quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

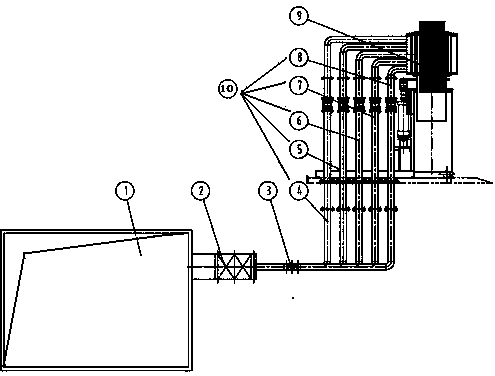

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] As shown in the figure, a multi-stage ring blower of hollow polyphenylene sulfide short fibers of the present invention includes an air conditioner 1, a main valve 2, a sub-valve 3, a graded air inlet device 10 and a ring blower device 9; the air conditioner 1 One end is connected with a graded air inlet device 10, the graded air inlet device 10 sequentially includes a first air inlet pipe 4, a second air inlet pipe 5, a third air inlet pipe 6, and a fourth air inlet pipe 7 from top to bottom With the fifth air inlet pipe 8, the surrounding blowing device 9 is connected to the other end of the grading air inlet device 10; the main valve 2 and the sub-valve 3 are located at the connection between the air conditioner 1 and the grading air inlet device 10, and the main valve 2 Located on the connection port of the air conditioner 1, the sub-valve 3 is located on the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com