One-piece thick seamless cropped trousers and its manufacturing method

A cropped trousers and one-piece technology, which is applied in the field of one-piece thick seamless cropped trousers, can solve the problems of easy stripping at the seams, cracks at the seams, and uncoordinated wearing, so as to achieve good thermal performance and high production efficiency. The effect of simple process and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to describe the present invention in more detail, it will be described below with reference to the accompanying drawings.

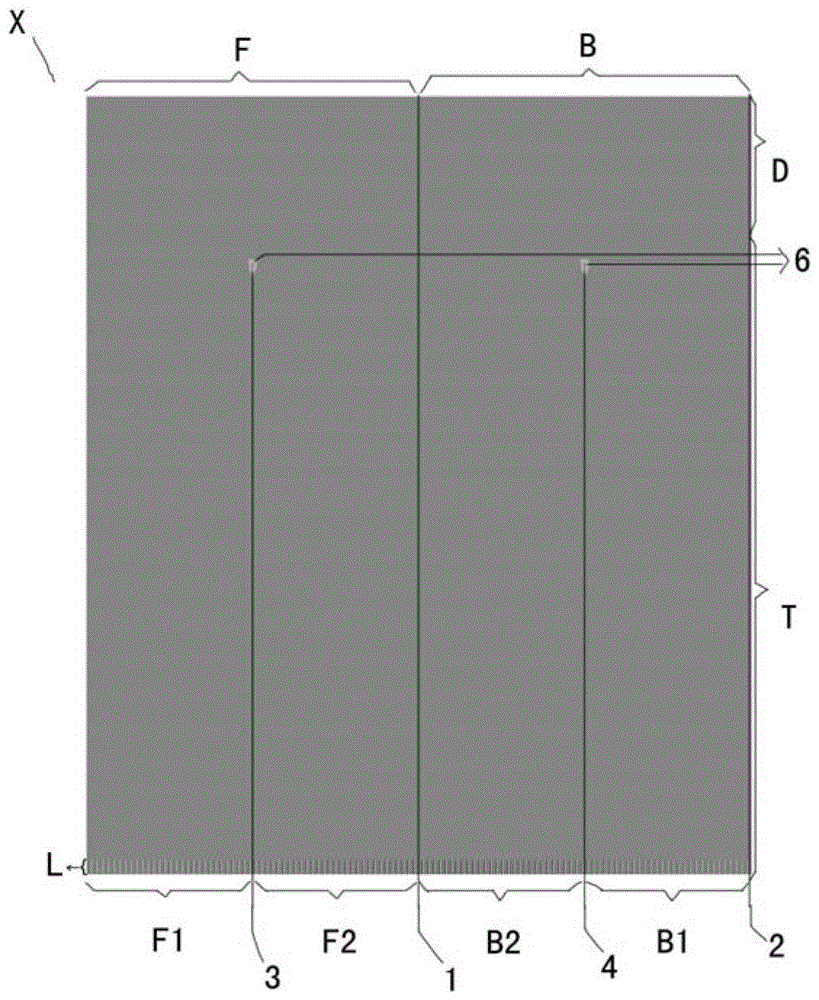

[0045] figure 1 It is a tiled view cut from the left side of the cropped trousers of the present invention. The ninth trousers X is divided into a front cloth piece F and a back cloth piece B as a whole, which is structurally composed of the waist, abdomen and crotch part D and the leg part T; the front cloth piece F and the back cloth piece B are on the right side of the ninth pants The split joint position 1 of the trousers and the split joint position 2 on the left side of the cropped trousers are connected. The leg part T of the ninth trousers X is composed of the left leg front cloth piece F1 and the left leg back cloth piece B1, the right leg front cloth piece F2 and the right leg back cloth piece B2, the left leg front cloth piece F1 and the left leg back cloth piece B1 is connected at the seam joint position 3 to form a cylindrical f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com