Seamless V-shaped crotch foot pants and its manufacturing method

A production method and seamless technology, applied in the field of heel pants, can solve the problems of cracks at the seams, too dense weaving, low efficiency, etc., and achieve the effects of simple production process, increased wear resistance, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

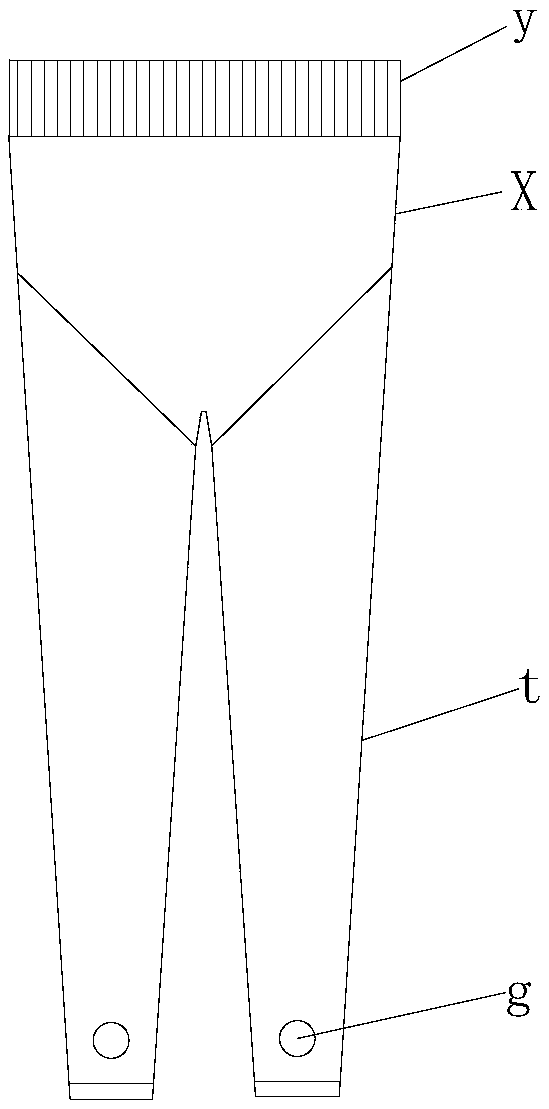

[0081] Such as figure 1 The seamless V-crotch step-on trousers shown include a trouser leg t, a seamless V-crotch X, a seamless waist y, and a heel opening g arranged on the trouser leg t. The seamless V-crotch X consists of a front The piece F and the back piece B are integrally knitted on a double-needle bed Raschel warp knitting machine, and the front piece F and the back piece B are seamed at the joint positions 1, 2, 3, and 4. Bonding technology connects seamlessly.

[0082] In this embodiment, the number of stitches of the front piece F and the back piece B of the seamless V crotch X are the same, and the fabric structure is also the same.

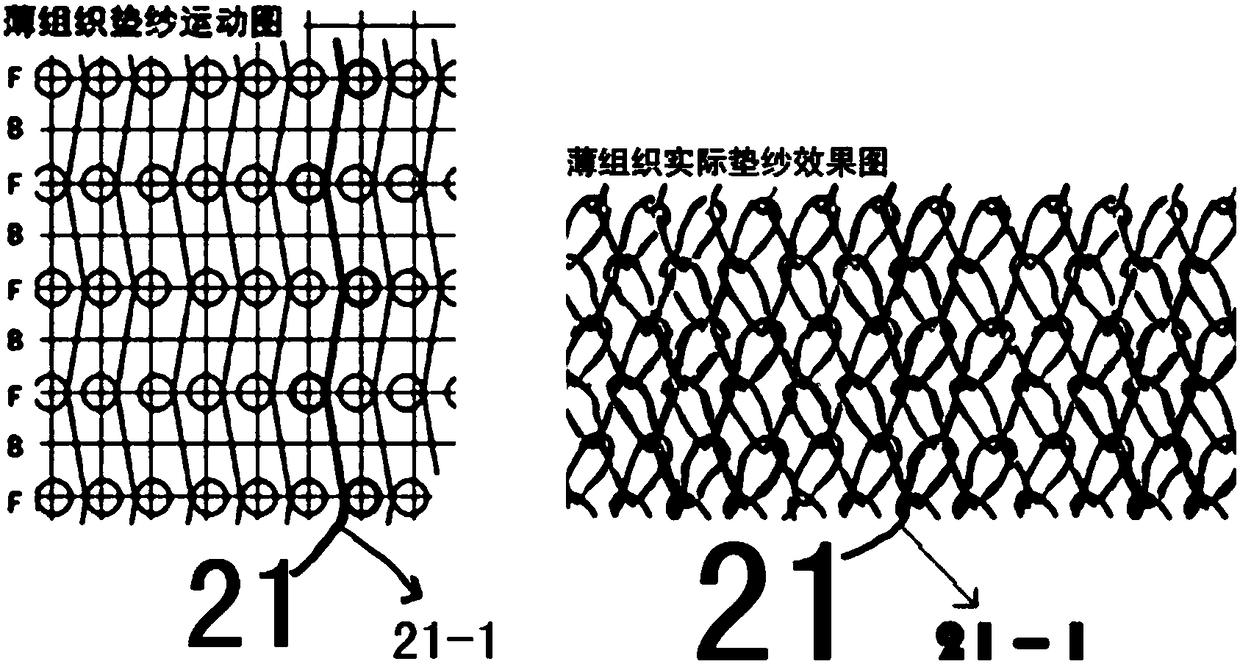

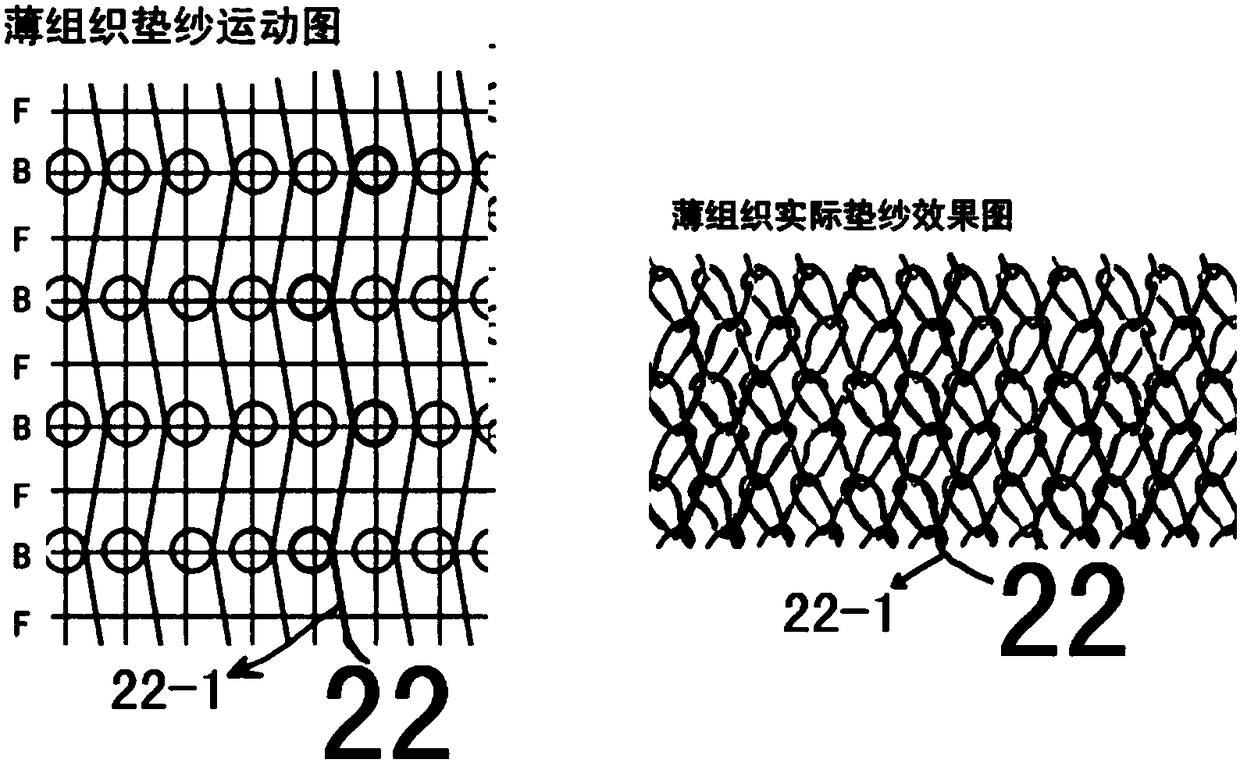

[0083] In this embodiment, the cloth surface weave of the seamless V-crotch X is knitted by two-needle warp plain weave in warp knitting technology.

[0084] combine figure 1 , Figure 1-4 and Figure 1-5 , this embodiment also discloses a method for making seamless V crotch trousers, which is characterized in that the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com