Film side sealing apparatus with closed-loop temperature control of a heater

a technology of temperature control and sealing apparatus, which is applied in the direction of transportation and packaging, packaging, transit packaging, etc., can solve the problems of difficult cleaning of wires without disturbing the gap setting or flatness of wires, loss of production time, and inability to achieve stable performance of dual side sealers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first alternate embodiment

[0049] Referring to FIG. 8, a front elevational view of the top belt guide 25 is shown having two elongated holes 72a, 72b to facilitate attaching the belt guide 25 to the sides of the side sealer 10 and adjusting the belt guide 25 against the lower portion of V-belt 16, which is positioned between top drive roll 12 and idler roll 14. The ends 71, 77 of the belt guide 25 are curved inwardly at a radius to correspond with the radius of the pulley rolls. In the preferred embodiment shown in FIGS. 8-10, the belt guide 25 is approximately 11 inches long, 2.56 inches high and 0.25 inch thick; however, other sizes of belt guide 25 may be implemented on a side sealer.

[0050] Referring to FIG. 9, a side elevational view of the top belt guide 25 shows a bottom groove 70 having a radius of approximately 0.06 inch so that the belt only protrudes slightly into the groove 70 to minimize any undesired frictional force.

[0051] Referring to FIG. 10, a bottom view of the top belt guide 25 shows the ...

second alternate embodiment

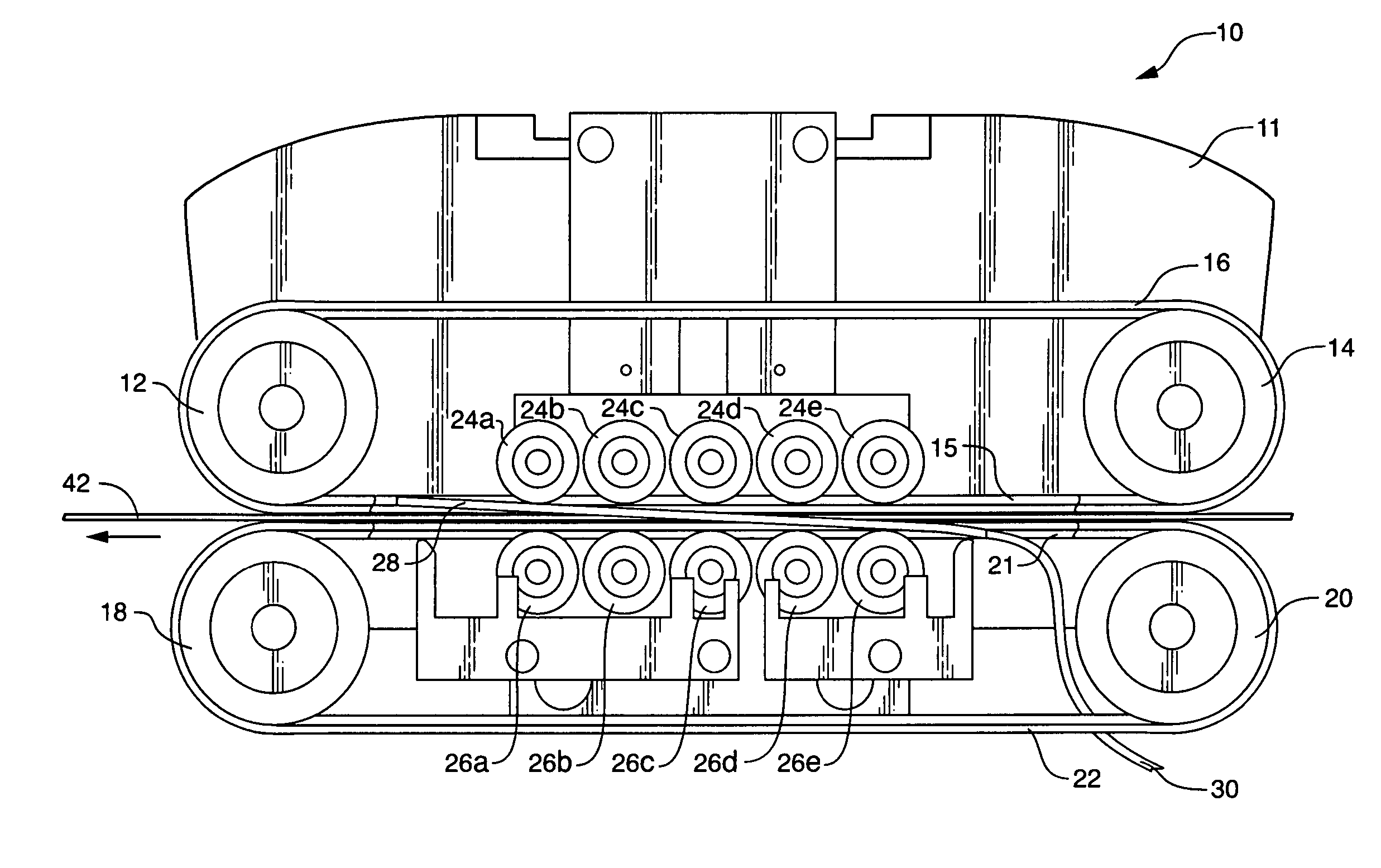

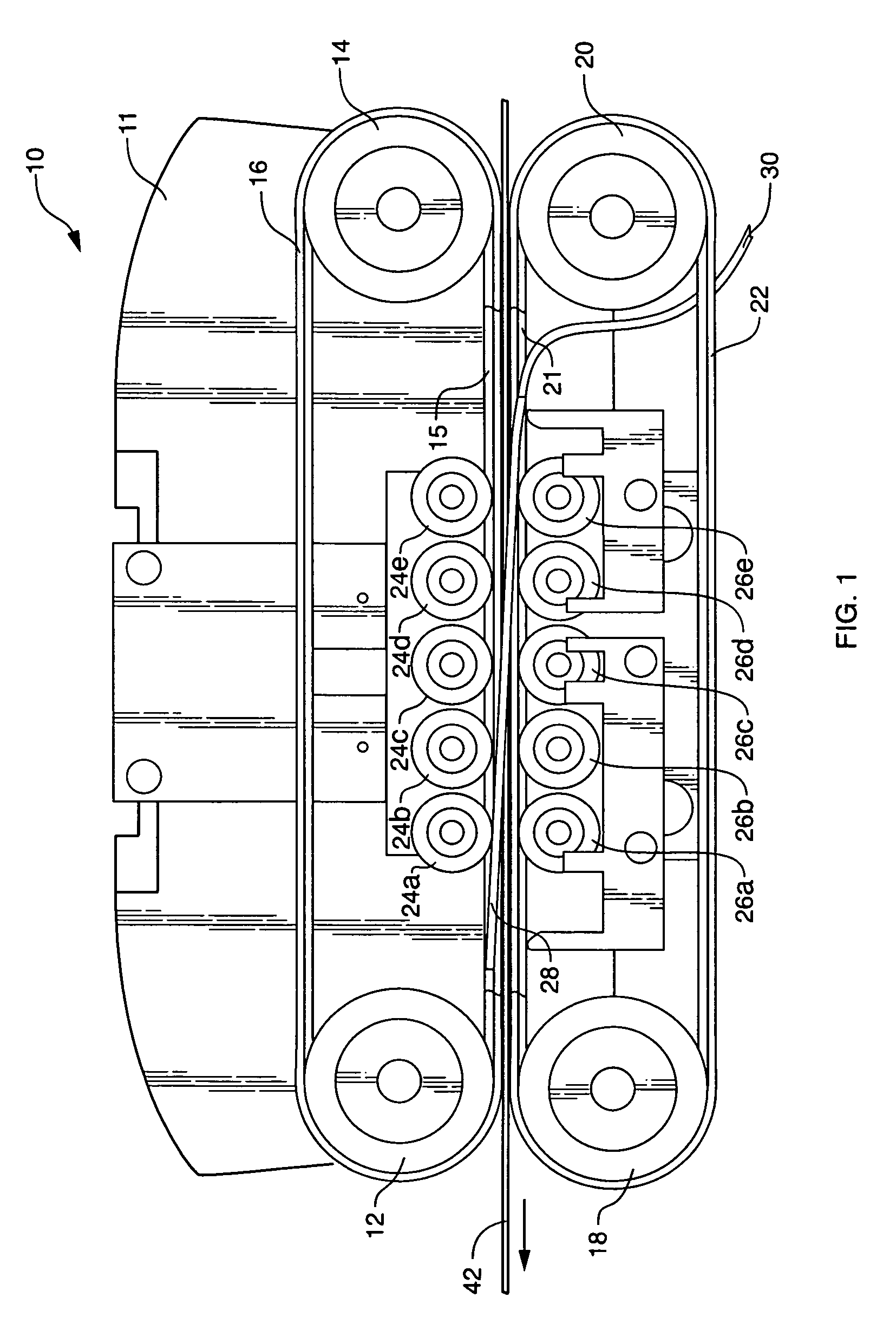

[0056] Referring to FIG. 14, a front elevational view of a second alternate embodiment of a side sealer 100 according to the present invention is shown. Elements of side sealer 100 which are the same as elements of the embodiment shown in FIG. 1 have the same reference number. The side sealer 100 performs a cutting and sealing operation the same as side sealer 10, but because of certain improvements to be described, the side sealer 100 performs a more efficient cutting and sealing operation near edges of a thermoplastic film 42 for covering a package 50 (FIG. 2) by eliminating lateral film 42 slippage while the film 42 is driven through the sealing process by the V-belts 15, 16, 21, 22. In some cases, the amount of thermoplastic film used is reduced with the side sealer 100 embodiment because of increased grip on the film 42. The cutting and sealing is performed using the heater 28. The second alternate embodiment shown in FIG. 14 employs a series of upper rotating rollers 124a-124e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com