Rotary pipeline compensator

A pipeline compensator, a rotary technology, applied in expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., which can solve problems such as reduced flexibility, inability to adjust, easy scaling or oxidation and corrosion , to achieve improved stability and consistent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

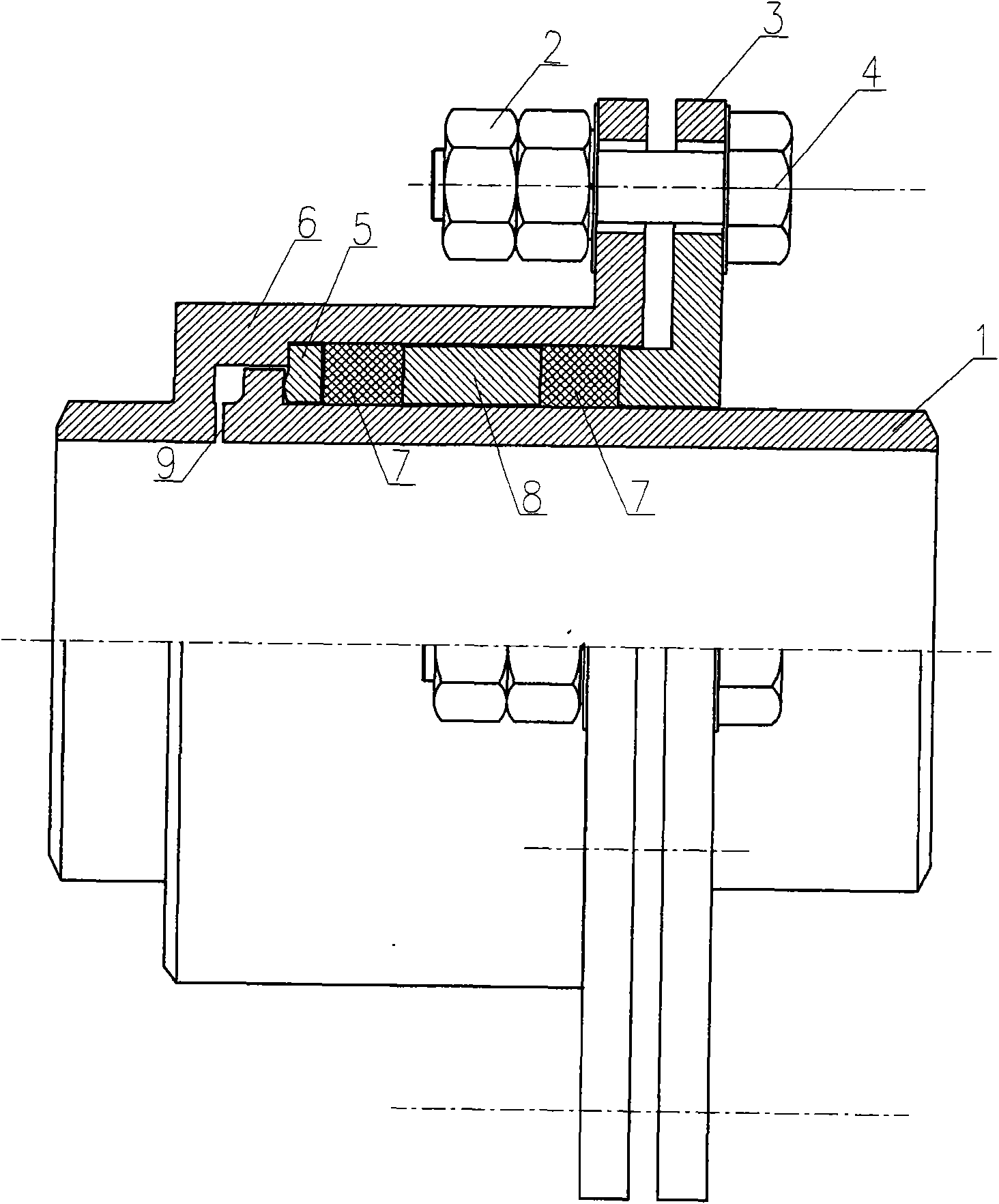

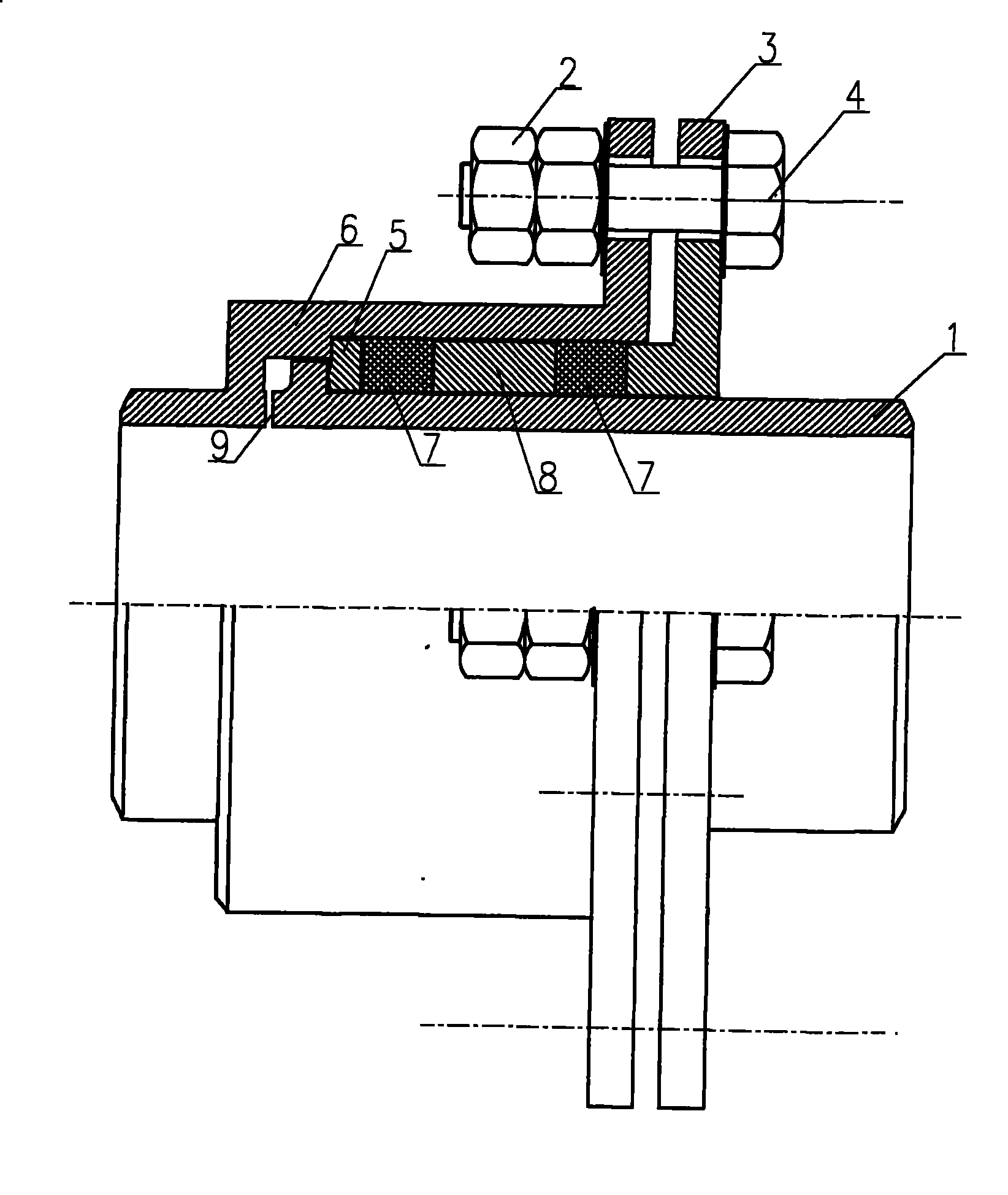

[0013] The rotary pipeline compensator shown in the drawings includes a main flow pipe 1, a nut 2, a gland 3, a screw 4, a sealing ring 5, a casing 6, a packing 7 and a casing 8. The main flow pipe 1 is inserted from the right end of the casing 6, and the annular boss on the outer wall of the left end of the main flow pipe 1 is matched with the inner hole of the casing 6 as a clearance fit. There is a sealed cavity between the main body outer wall of the main flow pipe 1 and the inner hole of the casing 6, from left to right The sealing ring 5, the packing 7, the sleeve 8, the packing 7 and the gland 3 are plugged in sequence on the right side. There are evenly distributed through holes on the end faces of the shell 6 and the gland 3. The screw rod 4 penetrates into the through hole and is connected by the nut 2 to press The cover 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com