Segmented self-standing anti-corrosion smoke exhaust inner sleeve for steel inner barrel chimney and construction method of segmented self-standing anti-corrosion smoke exhaust inner sleeve

A technology of inner sleeve and steel inner cylinder, which is applied in the field of chimney anticorrosion, can solve the problems of complex construction technology and connection structure, many failure links, etc., and achieve the effect of simple construction, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments of the present invention are described in detail below. The following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following Example.

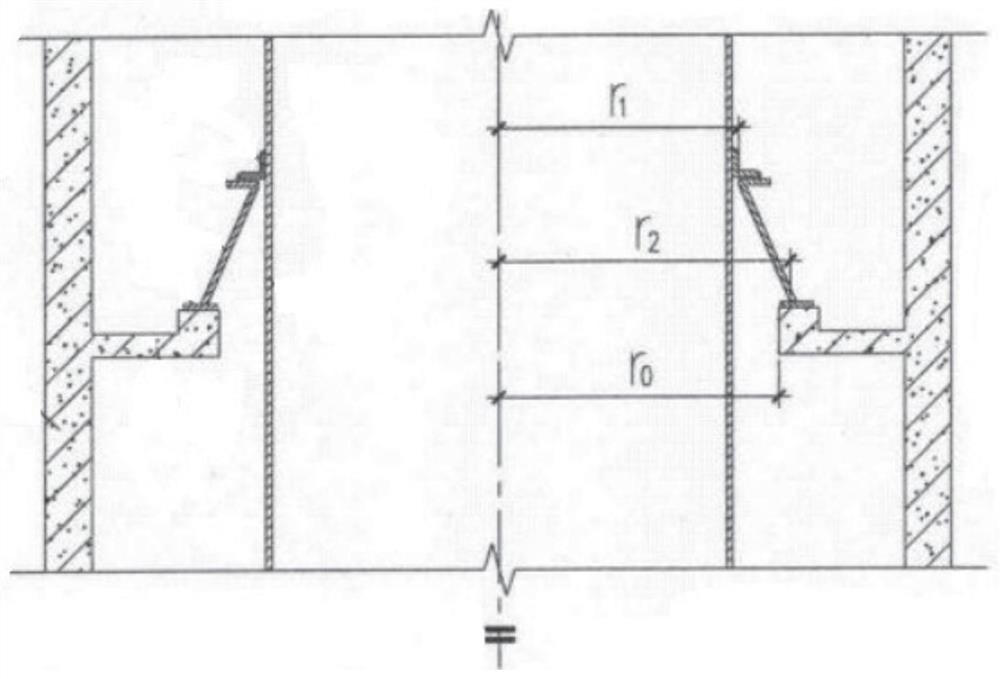

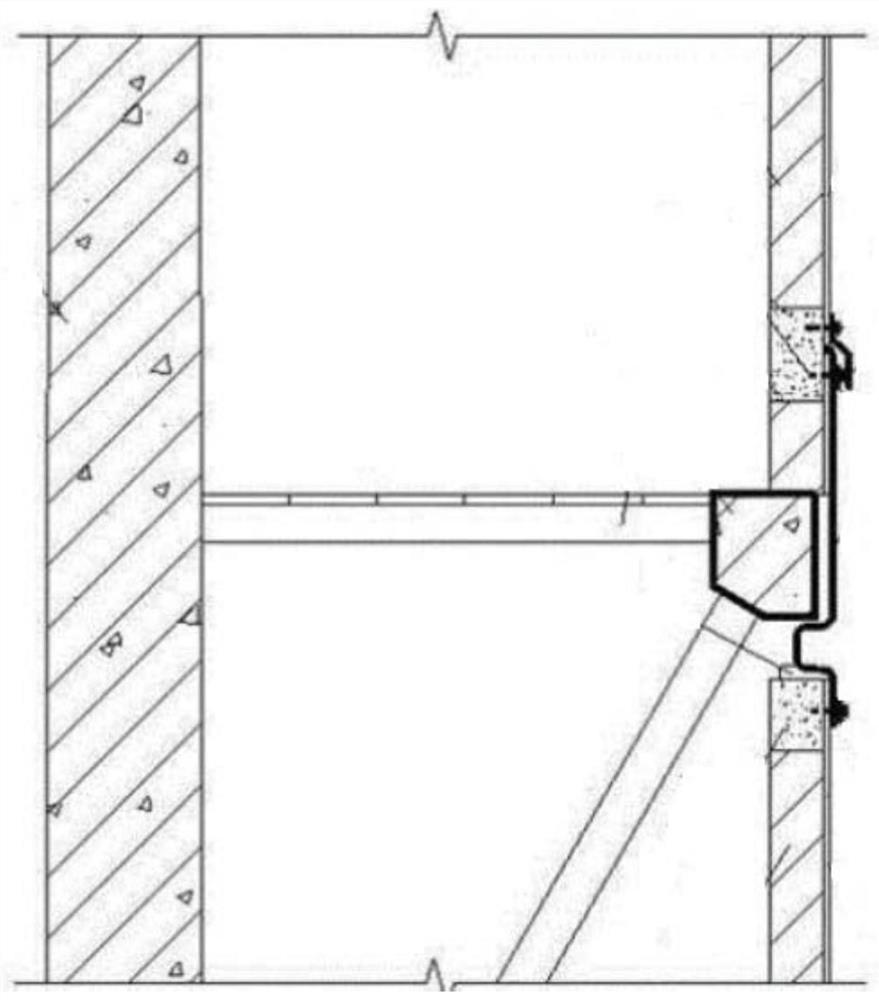

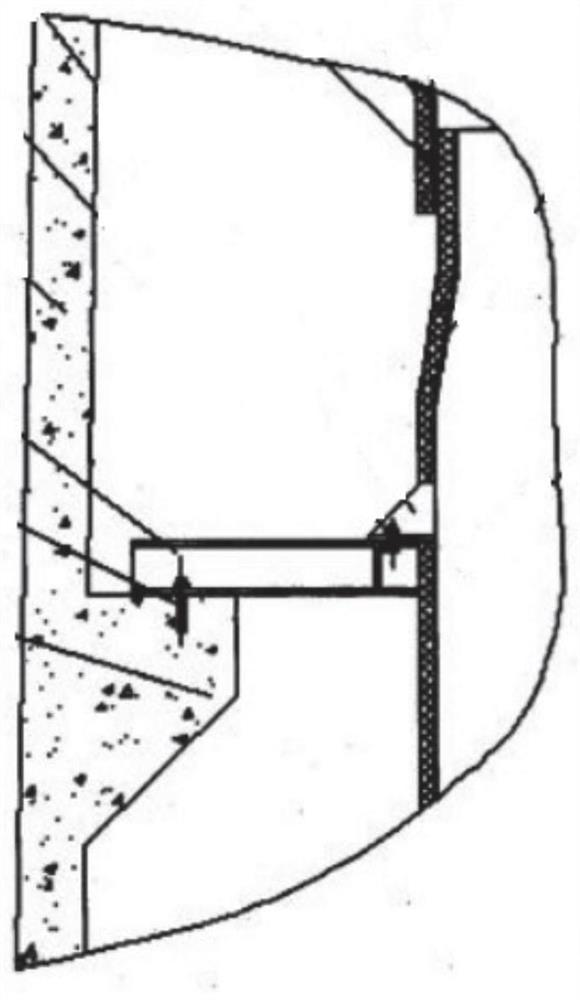

[0035] refer to Figure 5 , the present invention relates to the field of chimney segmented self-supporting anti-corrosion inner sleeves, providing a segmented self-supporting anti-corrosion smoke exhaust inner sleeve for steel inner tube chimneys, including a single-section inner sleeve 1, supported by at least two layers of segments Components 2, each segmented support component 2 is fixedly connected to the inner wall of the chimney inner cylinder 3, the single-section inner sleeve 1 is placed upright on the support base plate 4 of the segmented support component 2, and the segmented support components 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com