Construction method of pre-stressed high-strength concrete (PHC) pipe piles in deep ocean backfill area

A concrete pipe pile, high-strength technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of pile foundation construction difficulties, pipe pile breakage, pile head uneven force, etc., and achieve direct and indirect economic benefits Obviously, the pile loss rate decreases and the effect of reducing re-driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

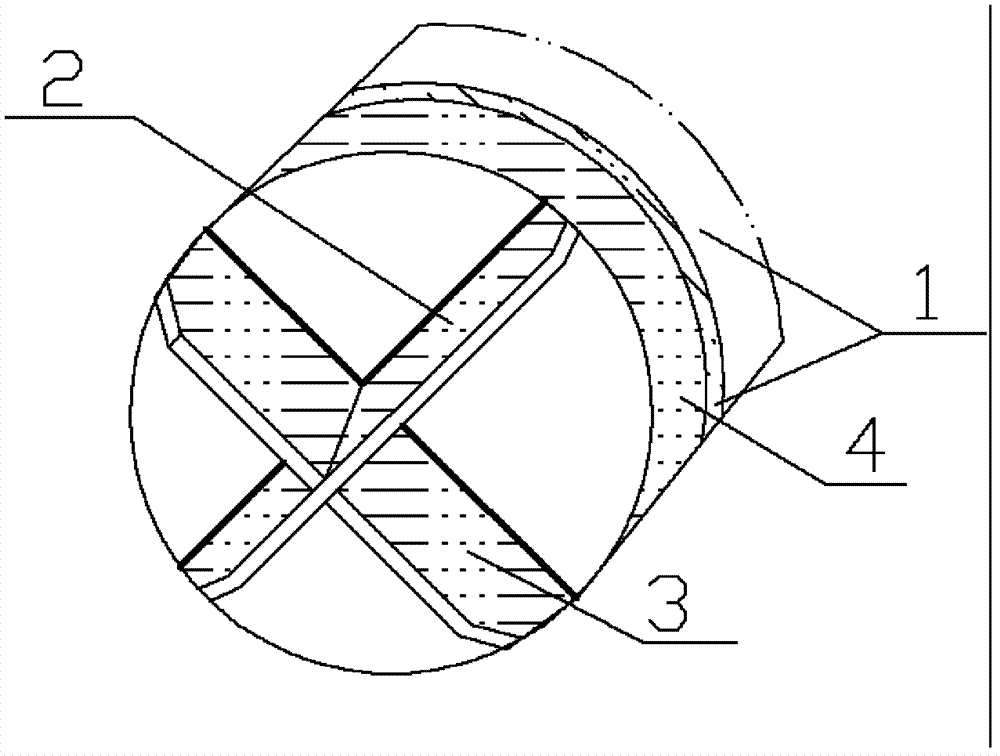

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention is a four-story above-ground building with a building area of 123480m built in the deep sea area of a harbor area. 2 The construction method of the prestressed high-strength concrete pipe piles used in the construction of the pipe pile foundation of the international logistics center with 60 50t large container trucks parked on the roof in the deep sea backfill area; The location of the karst ditch at the foundation cap and the geological conditions of the depth of the bearing layer are investigated in detail by the drilling method. depth, according to the measured position of the karst ditch and the depth of the bearing layer, the method and technology of pre-drilling and then piling at the pile sinking place should be formulated, and pre-drilling should be used in the hammer closing process. The standard penetration of the hammer with one strike for one strike, three strikes for non-pre-drilled holes and the total a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com