Selective catch separating device for trawl

A separation device and selective technology, applied in fishing nets, fishing, applications, etc., can solve problems such as difficulty in preventing fish and shrimp from remixing, achieve the effects of reducing manpower and working hours, reducing the burden of sorting, and improving the quality of catches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

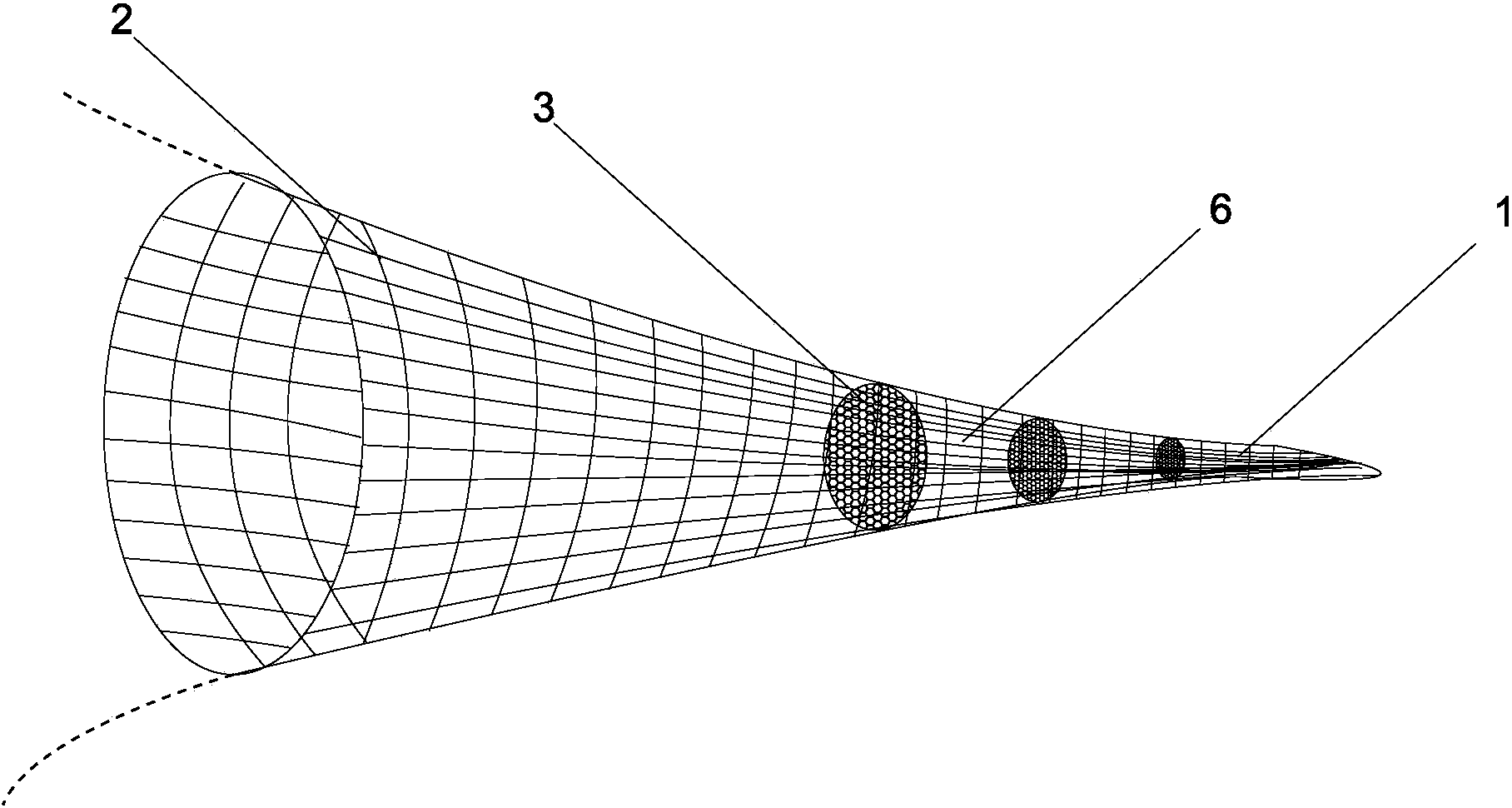

[0026] Such as figure 1 , Image 6 , Figure 7 and Figure 8As shown, a selective catch separation device for trawl nets includes a mesh bag 1 and a separation mesh 3 located at the closed end of the trawl net. After the trawl net is fully stretched, it is roughly conical and the separation mesh 3 is circular. The honeycomb-shaped regular hexagonal mesh is densely covered above, and the separation mesh 3 is drilled with a carbon fiber plate as a whole. Disassemble the connection, and form a mesh cavity when the mesh body is propped up, and the separation mesh 3 is arranged along the cross-sectional direction of the mesh cavity, and the periphery of the separation mesh 3 is all connected with the mesh body 2, and the size of the mesh 5 of the separation mesh is larger than the mesh body The mesh size of 2, the mesh of separation net sheet 3 is provided with long and flat elastic anti-escape closure bar 4. Separate mesh 3 into three pieces, divide the closed end of the trawl...

Embodiment 2

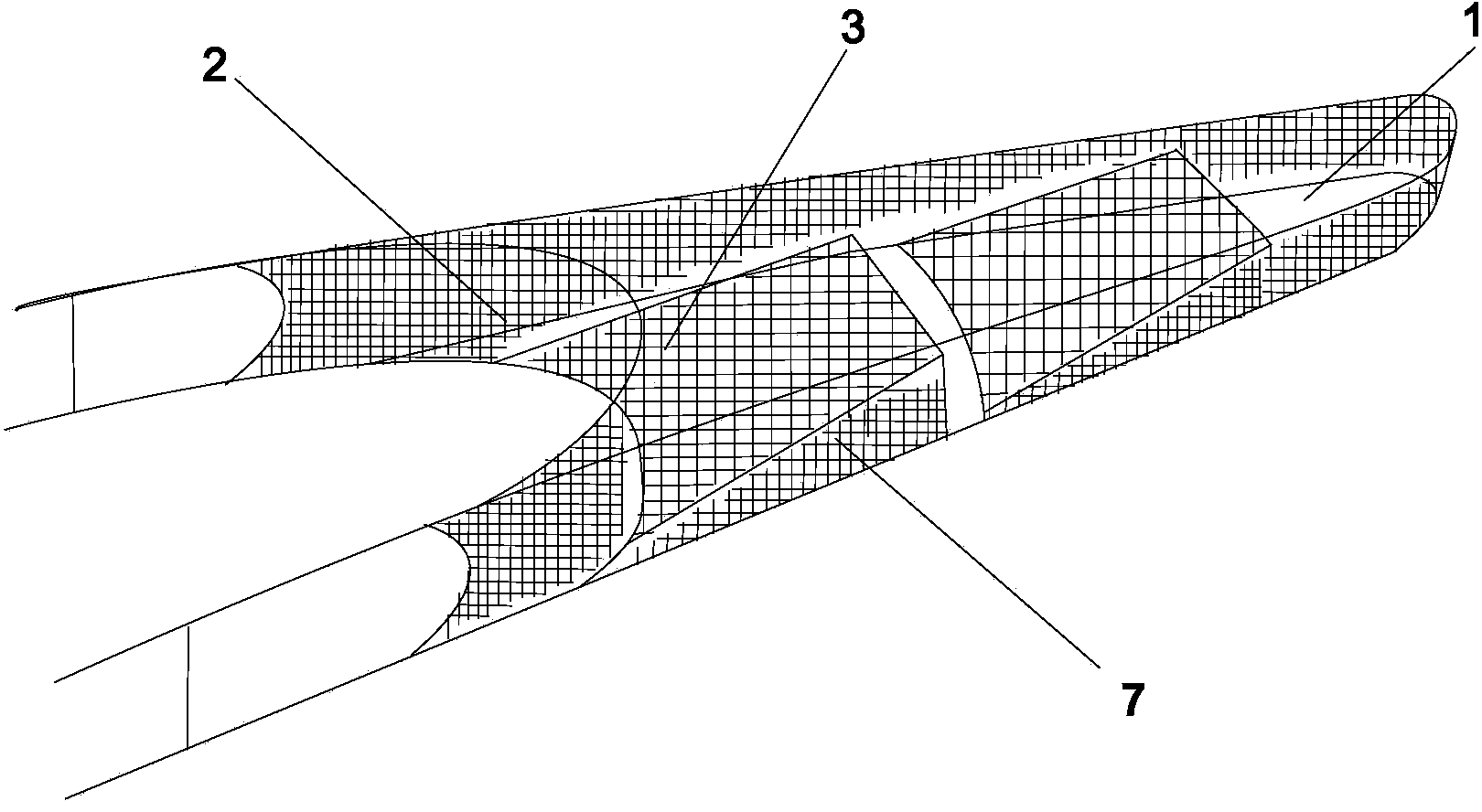

[0029] Such as figure 2 As shown, the trawl net is roughly in the shape of a sideways quadrangular truss after it is fully stretched out. Two separate mesh sheets 3 are arranged in the mesh cavity of the trawl net, and an inner cage structure 7 is respectively arranged on the net body 2 behind each separated mesh sheet 3. , the inner cage structure 7 is connected with the mesh body 2 and is located at the bottom of the mesh body 2, the separation mesh 3 is not arranged along the cross-section of the mesh cavity when the mesh body 2 is fully propped up, but is arranged obliquely, and the separation mesh 3 is trapezoidal , the bottom and two sides of the separated mesh 3 are tied with the bottom and sides of the net body 2 respectively with ropes, and the top edge of the separated mesh 3 is not tied with the net body 2, but only tied to the net by two ropes. The top of the body 2 keeps the separation mesh 3 in an inclined posture, so the separation mesh 3 and the axis of the me...

Embodiment 3

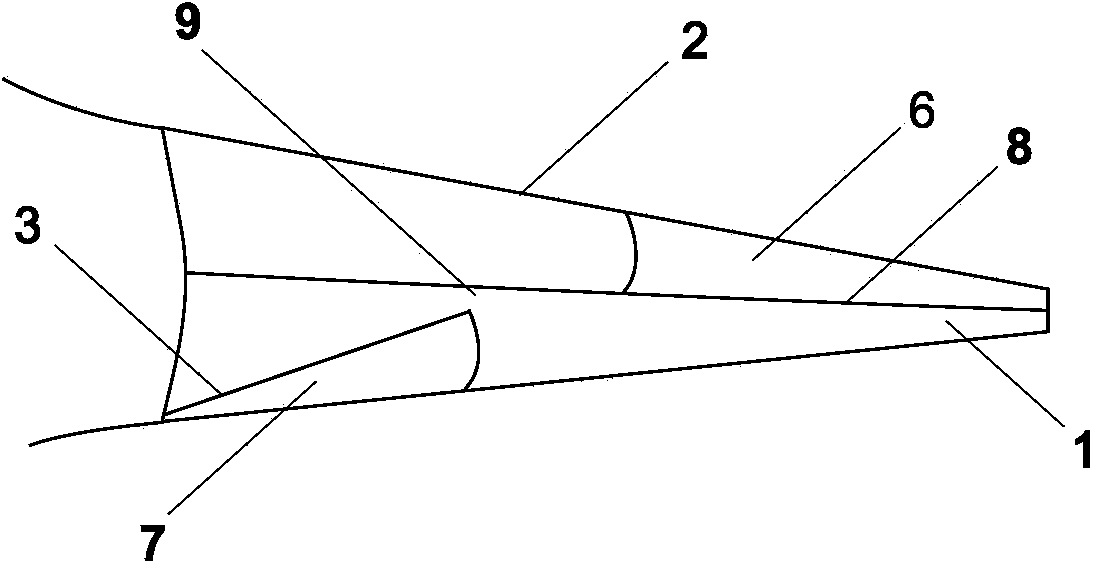

[0032] Such as image 3 , Figure 4 Shown, in the mesh chamber of trawl net, be provided with a partition mesh 8, partition mesh 8 is arranged along the horizontal axis section of the mesh chamber when net body 2, net bag 1 prop up completely, and partition mesh 8 extends from trawl net mouth to At the bottom of the mesh, a separation mesh 3 is provided on both sides of the separation mesh 8, and the separation mesh 3 divides the mesh cavity into two, thus having two mesh pockets 1. The separation mesh 3 is connected with the mesh body 2 and the separation mesh 8 at the same time, wherein the separation mesh 3 above the separation mesh 8 is arranged along the cross-section of the mesh cavity, and the position is deep in the mesh cavity, so that it is above the separation mesh 8 Constitute a cage structure 6; The separation mesh 3 below the separation mesh 8 is obliquely arranged at the near net mouth, and a gap 9 is provided between the separation mesh 3 and the separation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com