A spring hydraulic type riser string suspension device and suspension method

A spring hydraulic and suspension device technology, applied in earthwork drilling, wellbore/well parts, etc., can solve the problems of rig time occupation, poor operability, difficult operation, etc., to ensure functional reliability and stability, and avoid dynamic Compression, Manipulative Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

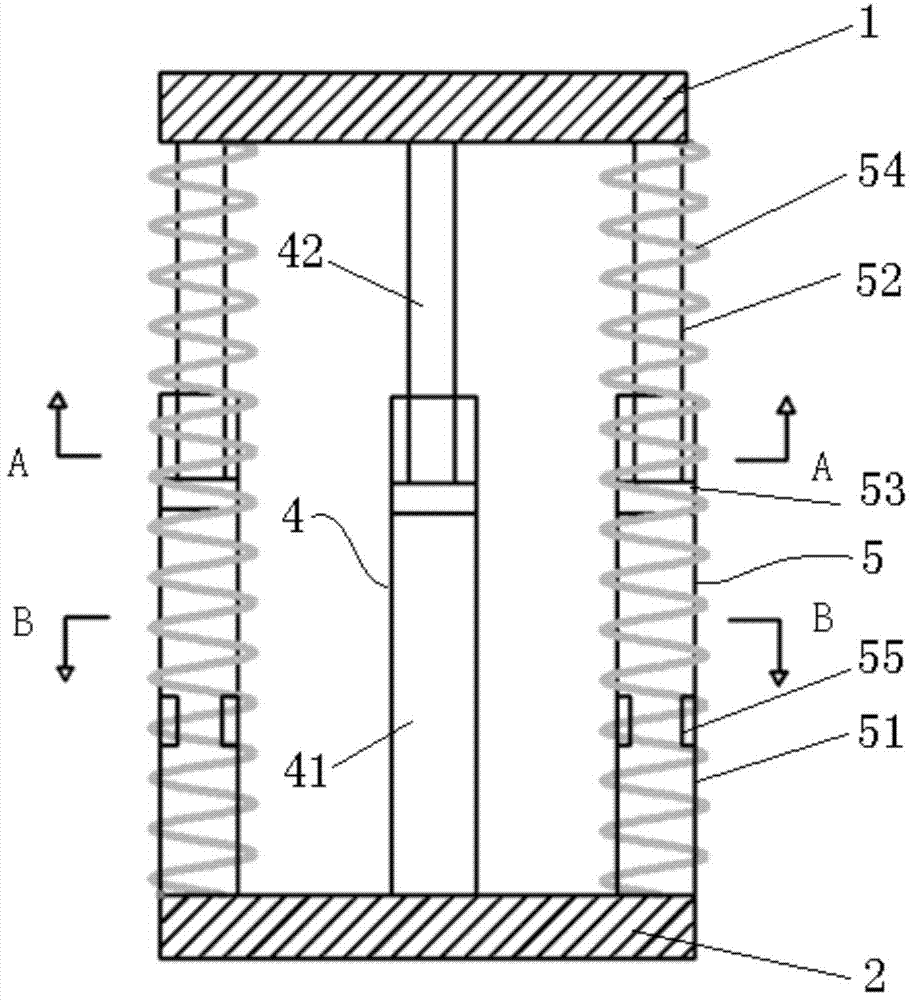

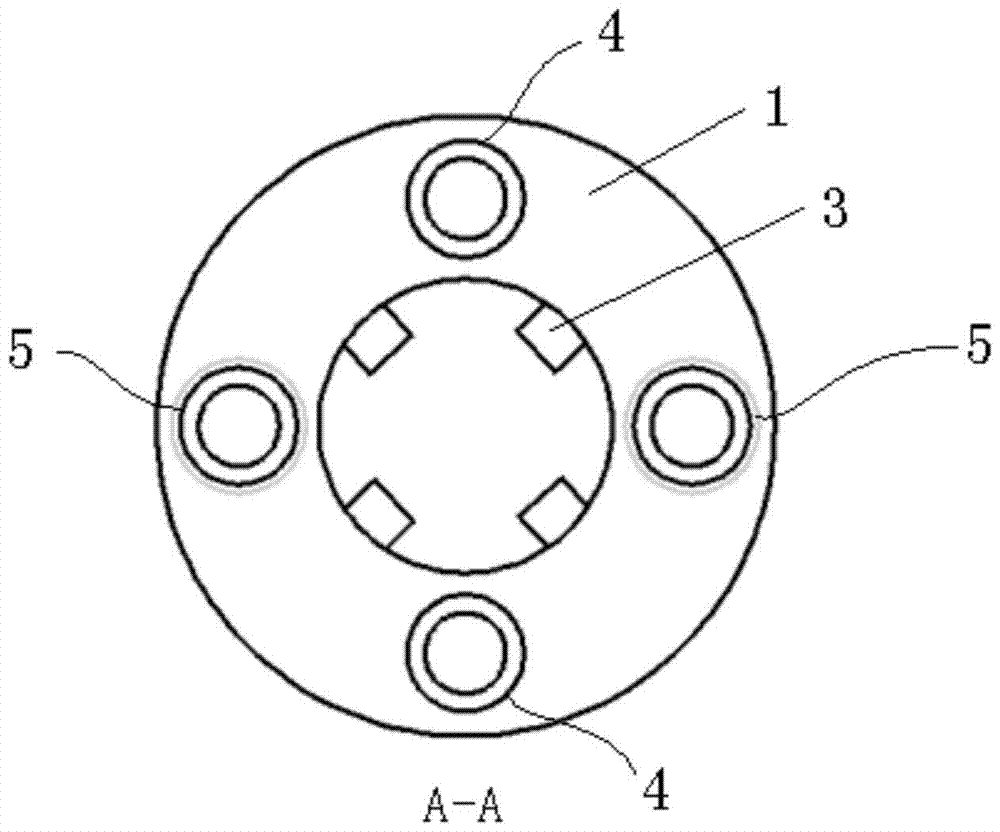

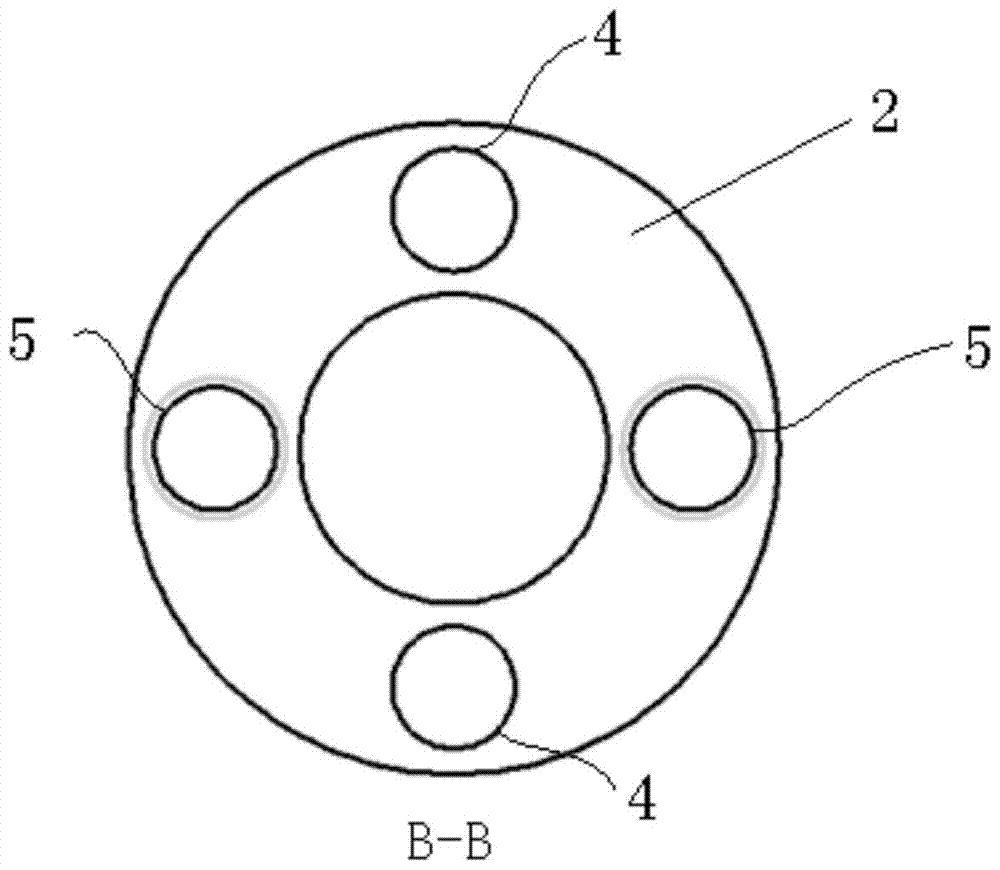

[0015] Such as Figure 1~3 As shown, the present invention proposes a spring-hydraulic type riser string suspension device, which includes an upper panel 1 and a lower panel 2 oppositely arranged up and down, and the upper panel 1 and the lower panel 2 are two annular structures with equal dimensions. A plurality of retractable pins 3 evenly distributed along its inner edge are arranged on the upper disk surface 1, and the pins 3 are controlled by a hydraulic or mechanical drive mechanism (not shown) arranged in the upper disk surface to protrude. Or retract. Two high-voltage uprights 4 and two normal uprights 5 are arranged between the upper panel 1 and the lower panel 2, and the high-voltage uprights 4 and the common uprights 5 are alternately arranged. The high pressure column 4 includes a hydraulic cylinder 41, the bottom of the hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com