Method of determining pump flow in rotary positive displacement pumps

一种旋转式、容积泵的技术,应用在旋转活塞式泵、旋转活塞式机械、测试/校准体积流量等方向,能够解决不能补偿泵性能、增加总体驱动系统成本和复杂性、不能用于确定旋转式容积泵泵流量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

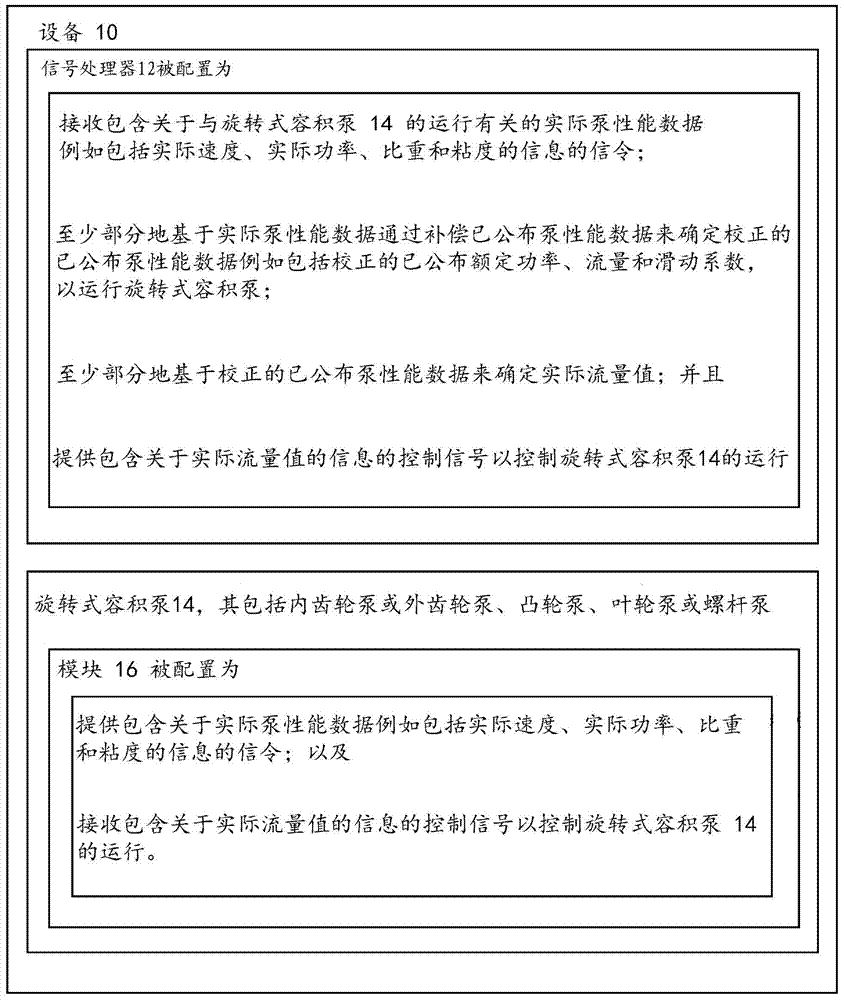

[0080] By way of example, such as image 3 As shown, according to some embodiments, the present invention may take the form of an apparatus 10 including a signal processor 12 that may be configured to control and protect the operation of a rotary positive displacement pump 14, which may include, for example, an internal gear pumps or external gear pumps, lobe pumps, vane pumps or screw pumps, or in the form of these pumps.

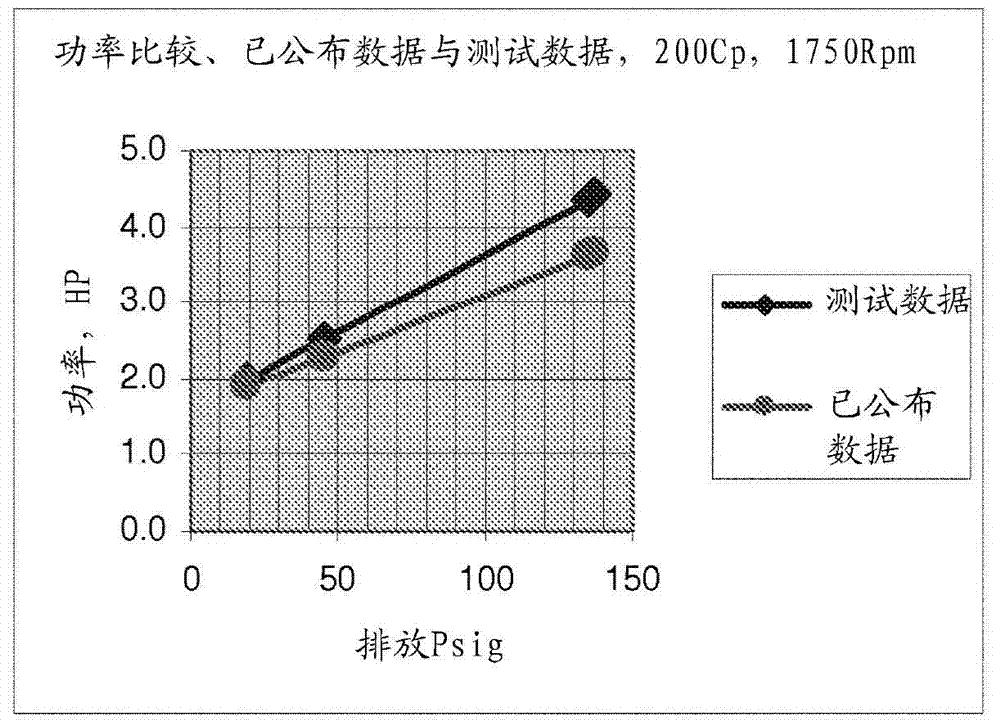

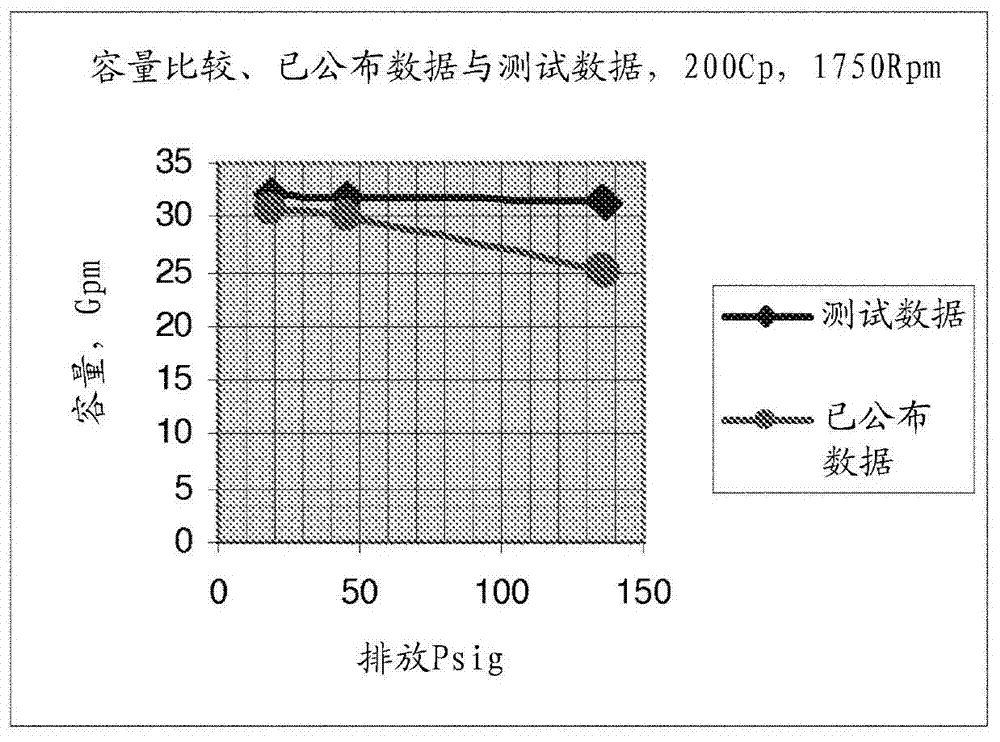

[0081] The signal processor 12 may be configured to receive signaling containing information about actual pump performance data related to the operation of the rotary positive displacement pump 14, and to determine the correction by compensating the published pump performance data based at least in part on the actual pump performance data. published pump performance data for operating the rotary positive displacement pump.

[0082] The signal processor 12 may also be configured to determine an actual flow value of the rotary positive displacement pump bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com