Calculation method of thermal performance of marine main engine cylinder working process

A technology of ship main engine and thermal performance, which is applied in calculation, special data processing applications, instruments, etc., can solve the problems of insufficient real-time performance, achieve the effect of reducing calculation complexity and improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in combination with specific embodiments.

[0027] Based on the mean value model, the invention uses the seiliger cycle to divide the operation process of the ship's main engine cylinder into a variable compression process, a constant volume combustion process, an isobaric combustion process and a variable expansion process, and calculates the thermal performance parameters of each process respectively.

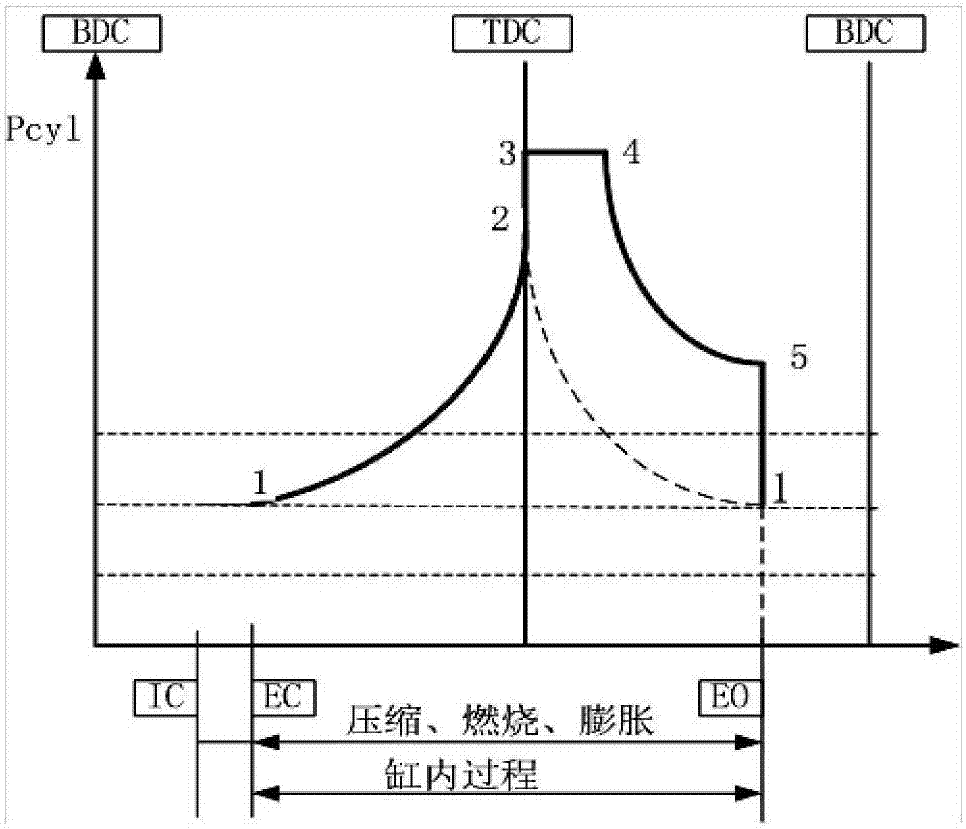

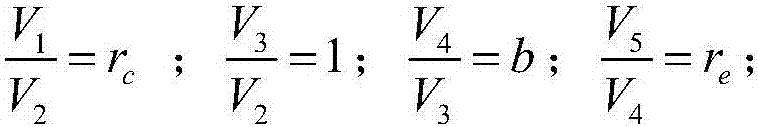

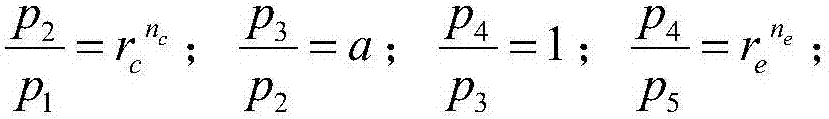

[0028] figure 1 It is the Seiliger cycle p-ψ, the abscissa ψ in the figure represents the crankshaft angle, the ordinate p represents the pressure in the cylinder, BDC is the bottom dead center, TDC is the top dead center, IC is the time when the scavenging hole is closed, and EC is the time when the exhaust valve is closed , EO is the opening time of the exhaust valve, 1-2 is the variable compression process, 2-3 is the constant volume combustion process, 3-4 is the isobaric combustion pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com