An adaptive bulging inlet shape control method based on flexible skin

A control method and air inlet technology, applied in the field of aeronautical structure design, can solve the problems of unadjustable three-dimensional profile and poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below.

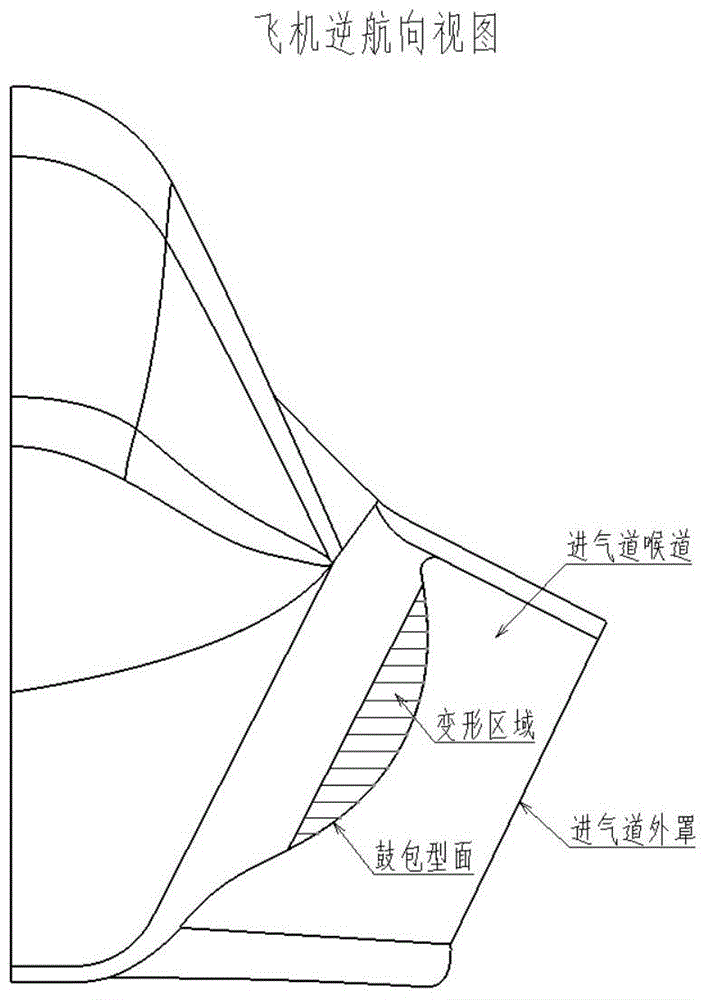

[0019] The bulge surface of the bulge air intake is a three-dimensional surface designed aerodynamically, and the area between the bulge surface and the air intake cover is the throat of the air intake, such as figure 1 shown. On the bulge surface, a certain area is selected as the deformation area of the bulge inlet. The deformed area is in the shape of an oblate spheroid, and its outline is generally elliptical, and may also be circular or other suitable shapes.

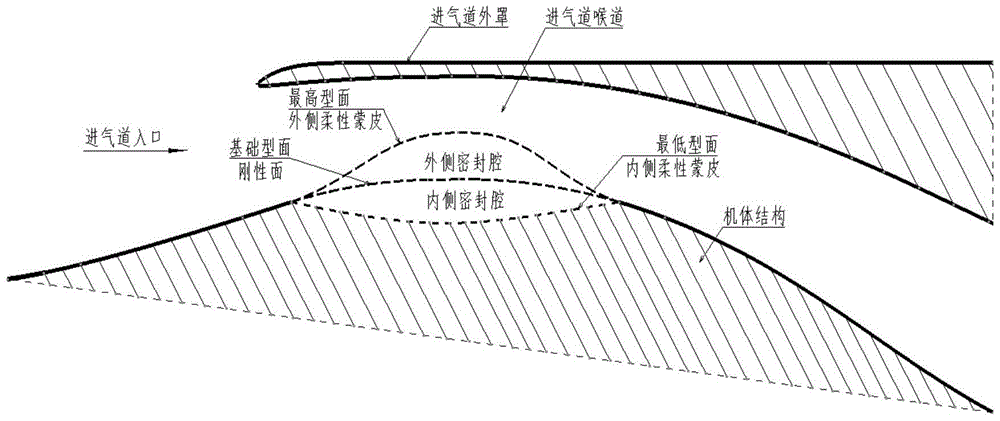

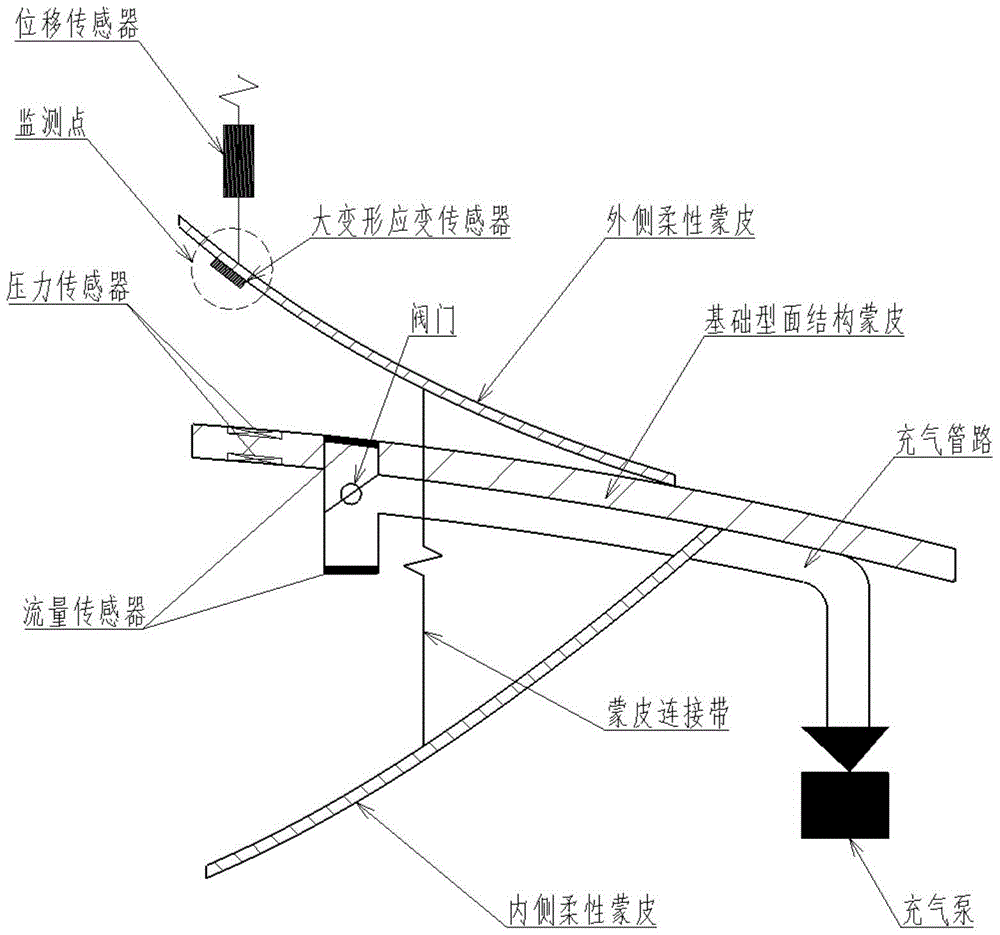

[0020] The initial position of the bulge profile is the base profile, which is a rigid surface and is usually made of metal materials such as aluminum alloy. In the deformed area, a layer of flexible skin is attached to the inner and outer surfaces of the basic surface ("inner side" is the side pointing to the plane of symmetry of the aircraft fuselage, and "outer side" is the opposite direction to "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com