Turbine blade strain field full-field measurement method based on dual-mode fusion

A technology of turbine blades and measurement methods, which is applied in the directions of measurement devices, optical radiation measurement, radiation pyrometry, etc., can solve the problems of difficult installation and wiring, obstacles to the stress and strain state of turbine rotor blades, and low upper limit of strain field application temperature. Strain situation accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

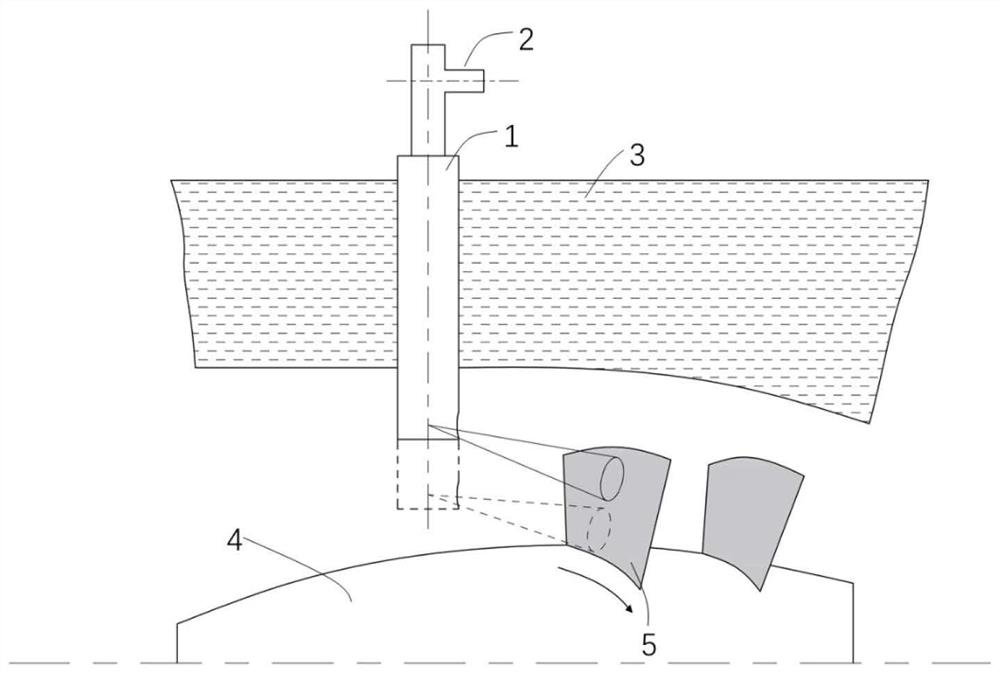

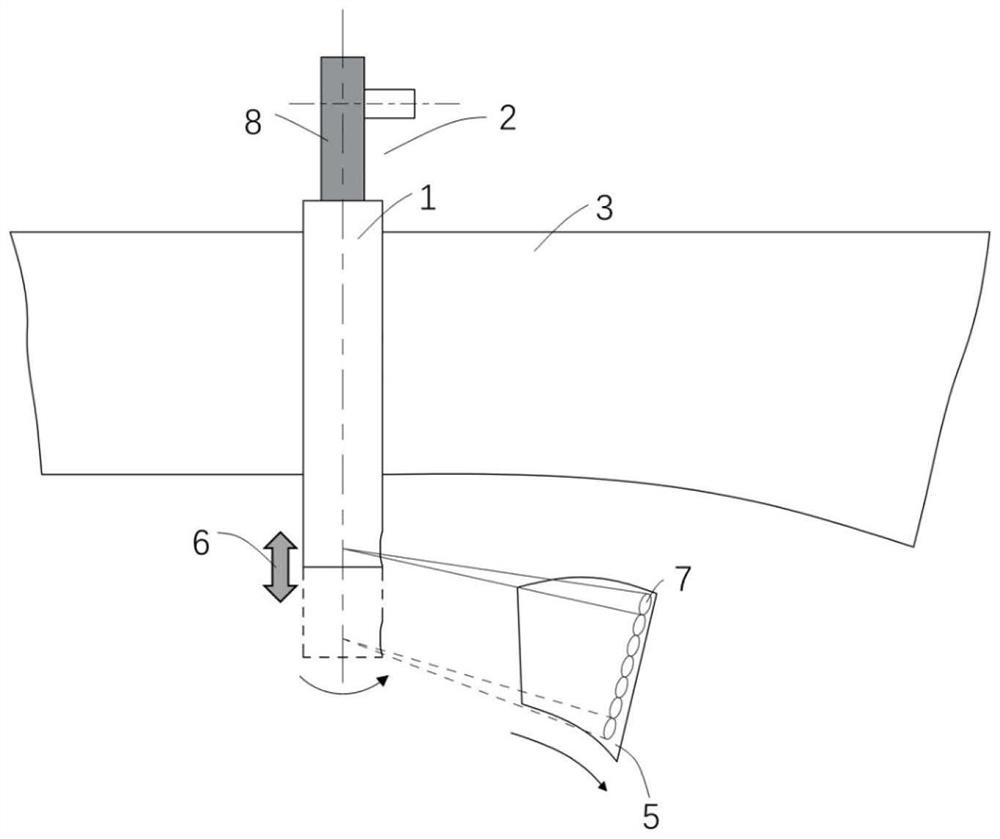

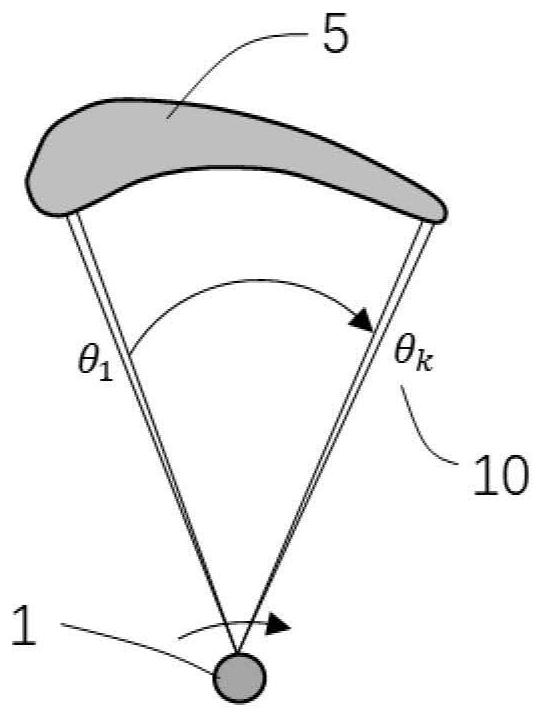

[0032] Such as figure 1 As shown, the dual-mode probe 1 enters the interior of the engine through the reserved hole of the engine casing wall 3, and the inside of the engine casing wall 3 mainly includes the engine shaft 4 and the turbine blades 5, and the turbine blades 5 are exposed to high temperature and high pressure. High-speed rotation in a gas environment, thereby driving the rotation of the engine shaft 4, the dual-mode probe 1 will put the probe used for sensing into the engine, and the probe will cooperate with the light hole through a reflector , transmitting the optical information of the blade along the probe tube to the dual-mode optical path 2 at the rear end of the dual-mode probe 1 , the dual-mode optical path 2 mainly includes an imaging optical path 8 and an infrared optical path 1 .

[0033] Aeroengine turbine blades work in an extreme environment of high temperature and high pressure, but the turbine blades are in the steady state of the engine. Due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com