Detection stage actuating mechanism

A technology of actuator and torque output, which is applied in the field of torque monitoring structure to achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

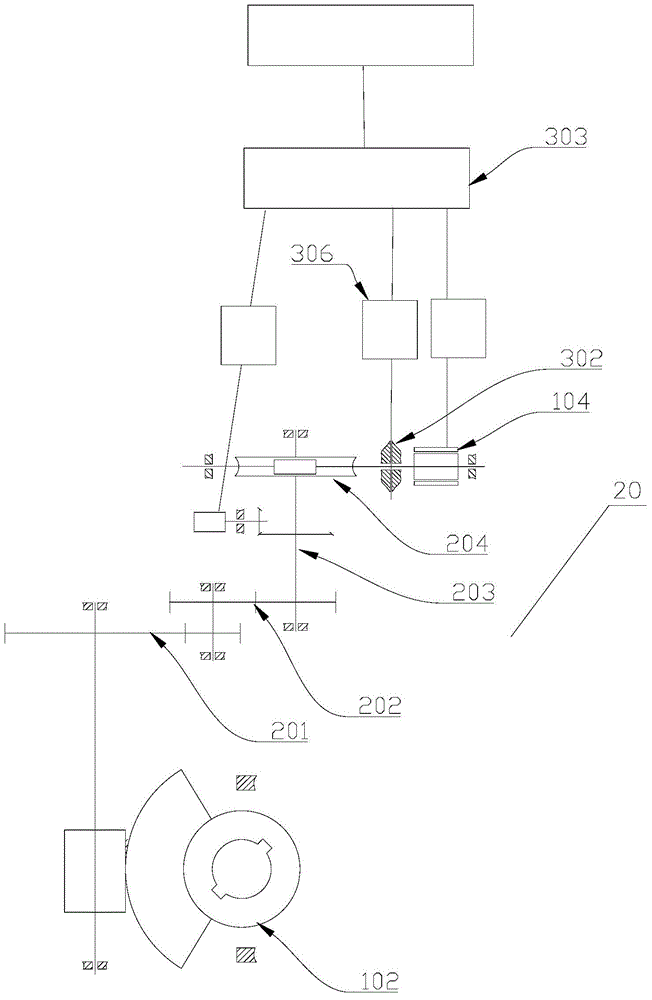

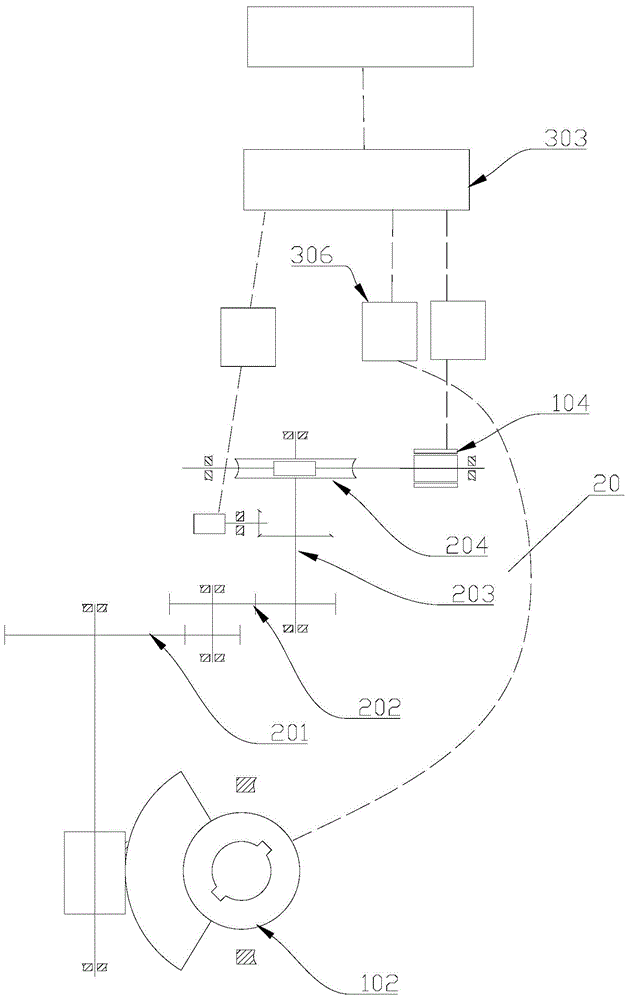

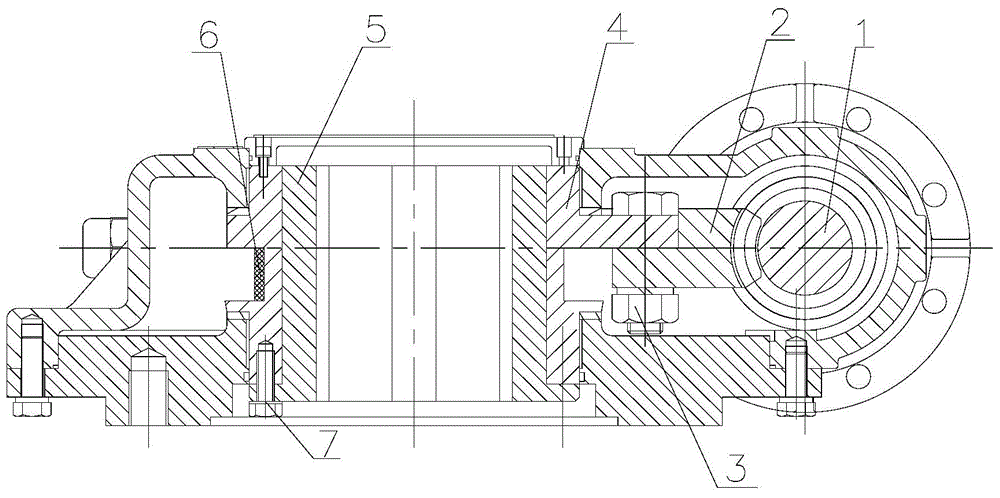

[0026] Such as Figure 2~4 As shown, a detection-level actuator includes a housing, a controller 303, a motor 104, a reducer 20, and a final torque output end 102 for driving the valve to open and close. The reducer 20 is connected to the motor 104 in transmission, The final torque output end 102 is connected to the output end of the speed reducer 20 through transmission, and the final torque output end 102 is fixedly covered with a torque sensor 6, and the torque data on the final torque output end 102 is obtained by the torque sensor 6, that is, the valve Running torque data, and transmit the data to the controller 303;

[0027]Specifically, the final torque output end 102 includes a valve stem joint 5 for connecting the valve, and a hub 4 fixedly sleeved outside the valve stem joint 5, and the hub 4 is fixedly connected to transmit power for driving the hub 4 to rotate. Components, the torque sensor 6 is fixed on the final torque output end 102 on the surface of the hub 4,...

Embodiment 2

[0029] Such as Figure 5 As shown, as a further improvement of Embodiment 1, a second torque sensor 302 is also included. The second torque sensor 302 is installed at the output end of the motor 104 for collecting torque data at the output end of the motor 104. The second torque sensor 302 is installed at the output end of the motor 104. The torque sensor 302 is in signal connection with the controller 303 . Utilize the second torque sensor 302 to directly obtain the output torque of the motor 104, thereby monitor the real-time state of the motor 104 output torque, and then monitor whether the running condition at the motor 104 place is normal, then two places (motor 104 output terminal and final torque output terminal 102 ) torque data, real-time monitoring of the torque transmission efficiency of the entire electric actuator can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com