Car Seat Quick Test Tool

A car seat, fast technology, applied in the direction of measuring devices, instruments, mechanical devices, etc., can solve the problems of wasting human resources and site resources, unfavorable resource allocation, increasing management pressure, etc., to reduce the workload of operation and transportation , Extensively promote the value and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

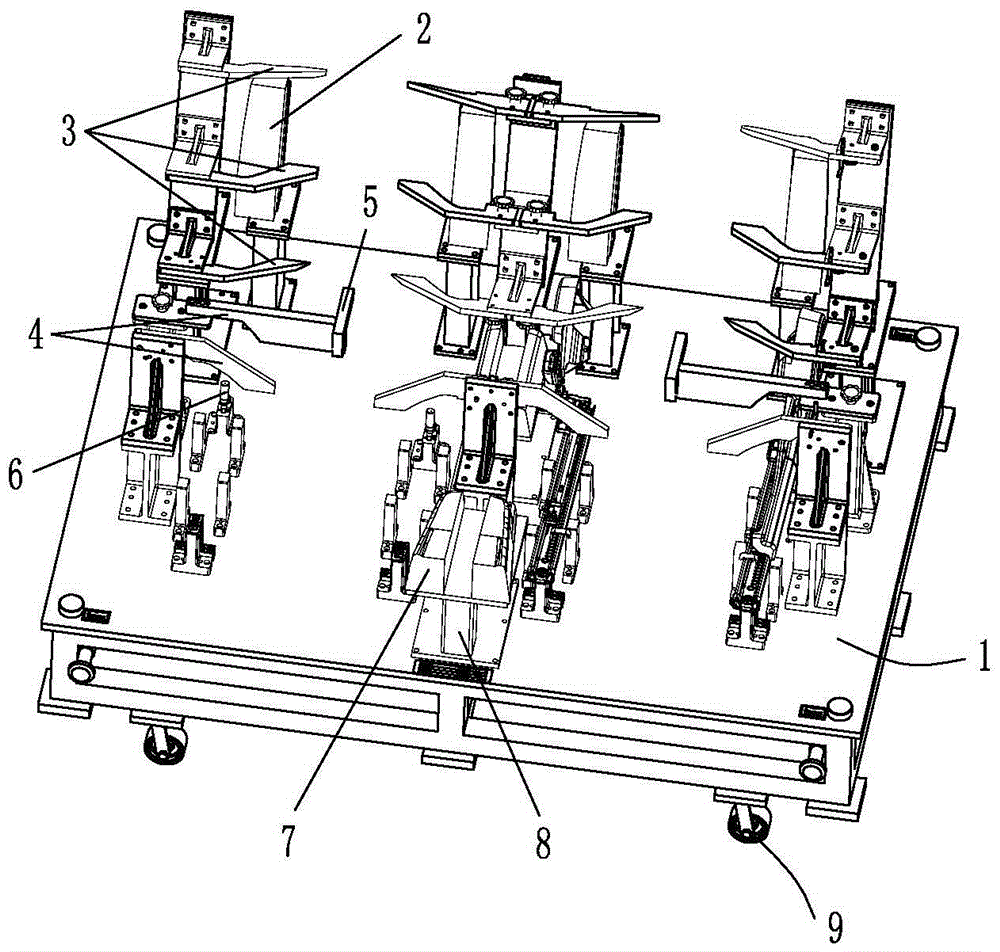

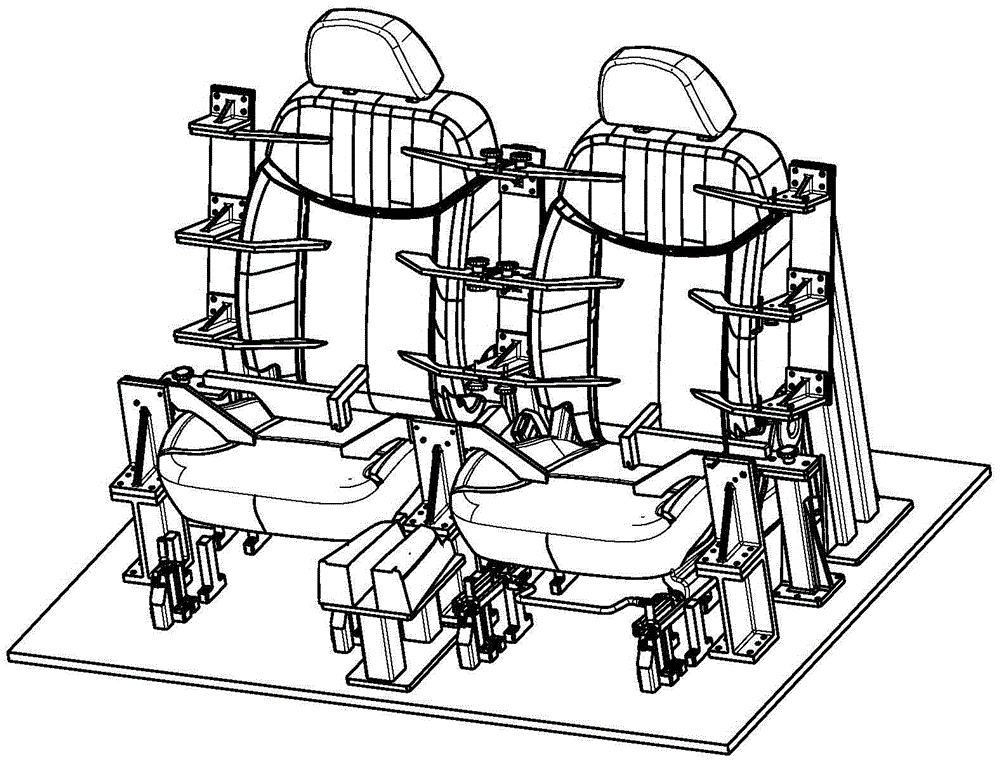

[0014] combine figure 1 —— figure 2 As shown, a quick inspection tool for a car seat is mainly composed of a base plate 1, a fixed support 2, a backrest foam two-wing detection block 3, a seat cushion foam two-wing detection block 4, an H point detection block 5, a seat and a body Assembly hole detection pin 6 and limit position seat foam and center console gap detection type block 7 are composed of several parts. The figure shows the double-seat inspection fixture, and now only the single-seat inspection fixture is described.

[0015] Four universal wheels 9 arranged in a rectangular shape are arranged below the bottom plate 1 to facilitate the movement of the entire seat inspection tool. The fixed support 2 is fixed above the bottom plate 1, and the fixed support 2 is used for installing each detection block and seat of the fixed inspection tool. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com