A kind of elastic anti-loosening nut

An anti-loosening nut and elastic technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of mechanical failure, poor fastening effect, and bolts coming out of the threaded hole of the nut, etc. The effect of looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

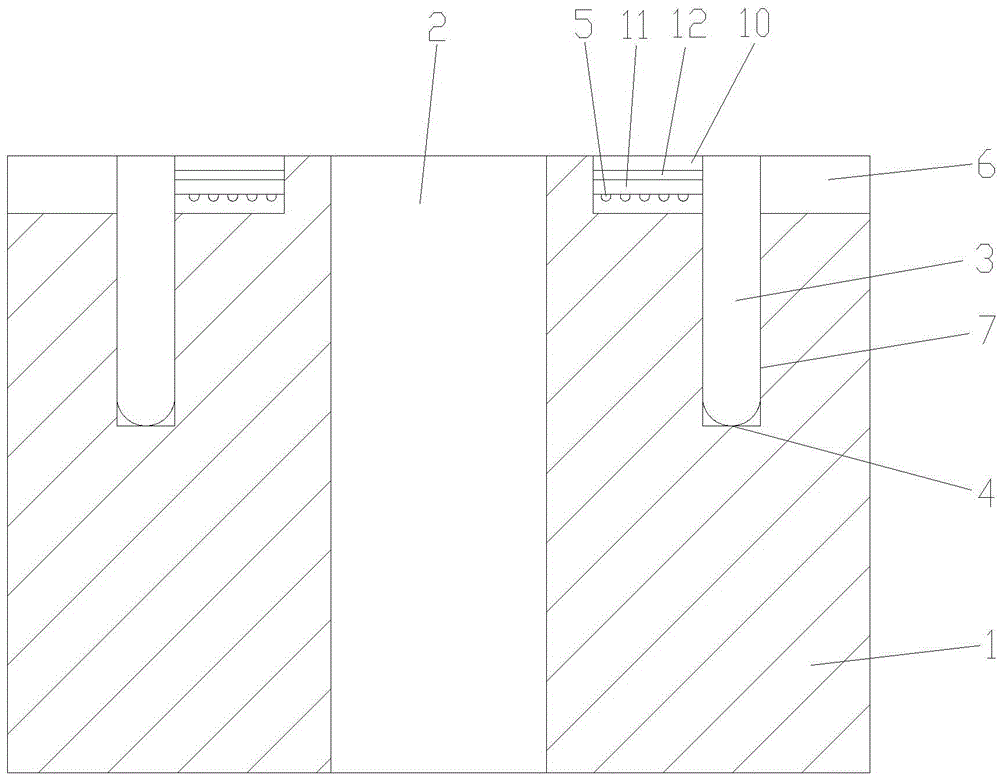

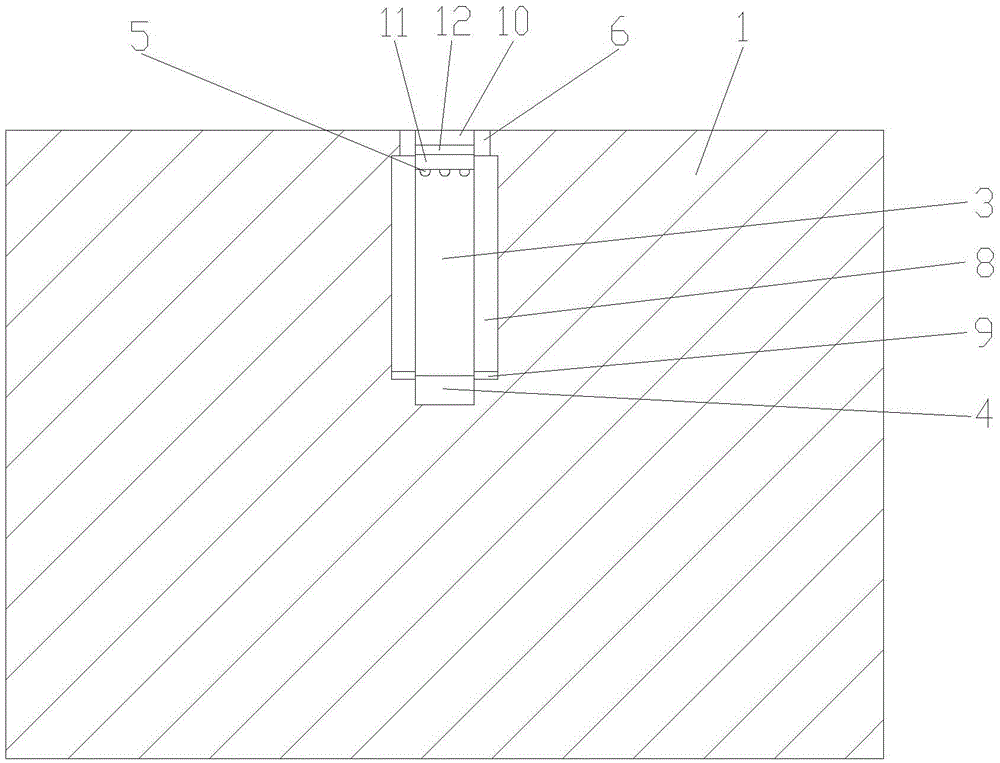

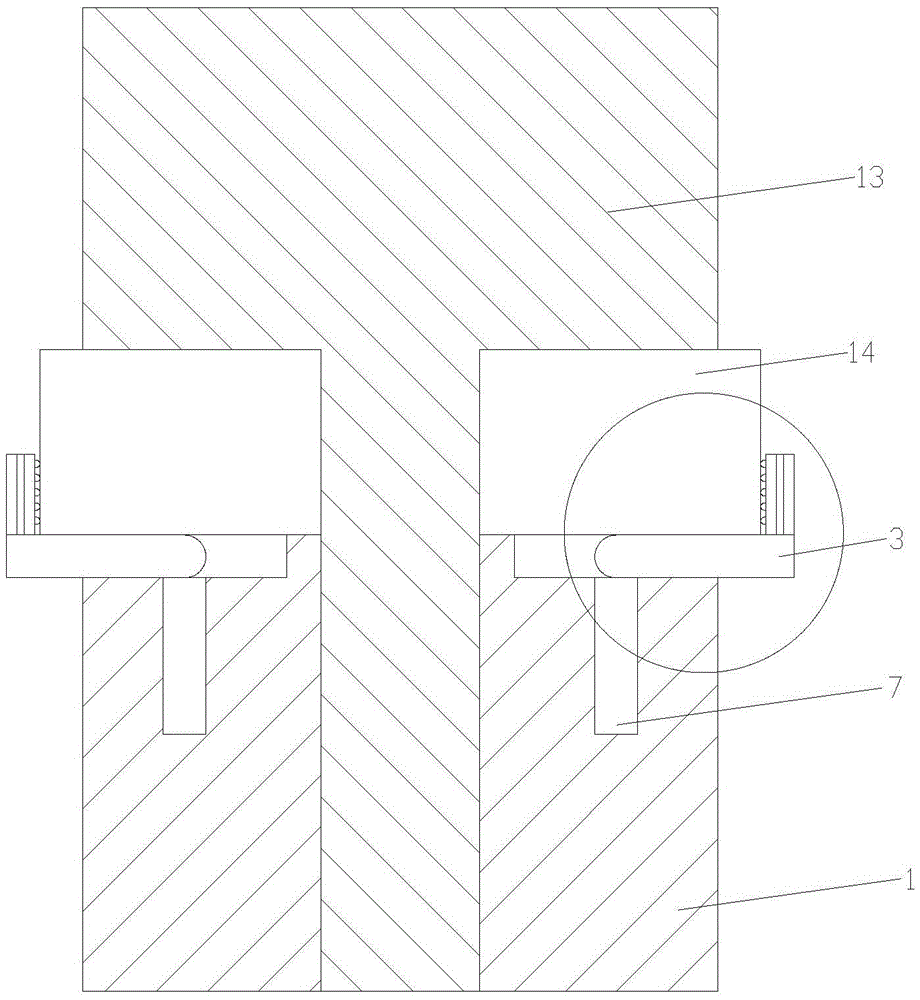

[0016] as attached figure 1 , 2 The shown elastic anti-loosening nut of the present invention includes a nut body 1 with a threaded hole 2 inside and two "L" shaped turning blocks 3; the "L" shaped The bottom of the "I" part of the turn block 3 is a rounded corner 4; the inner end surface of the "-" part of the "L" shaped turn block 3 is provided with a plurality of protrusions 5 in an array; the nut body 1 is symmetrically opened with Two horizontal grooves 6; the horizontal groove 6 communicates with the outside world; the nut body 1 also has a vertical receiving groove 7 communicating with each horizontal groove 6; each "L" shaped turning block 3 The "I" part is accommodated in a housing groove 7; when the "I" part of the "L"-shaped turning block 3 is accommodated in the housing groove 7, the "-" part of the "L"-shaped turning bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com