Scanning test machine

A testing machine and code-scanning technology, which is applied in the field of code-scanning testing machines, can solve problems such as poor battery durability and low battery acceptance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

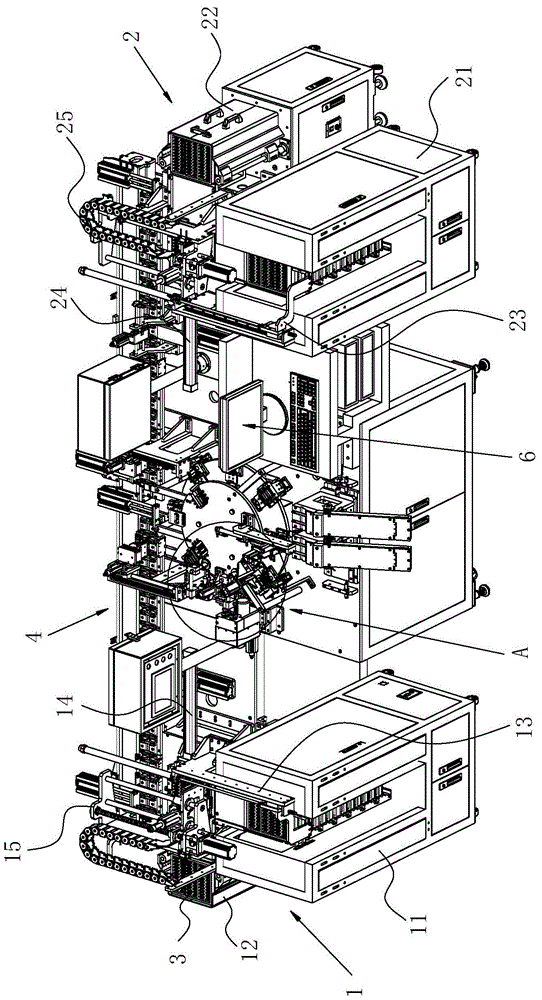

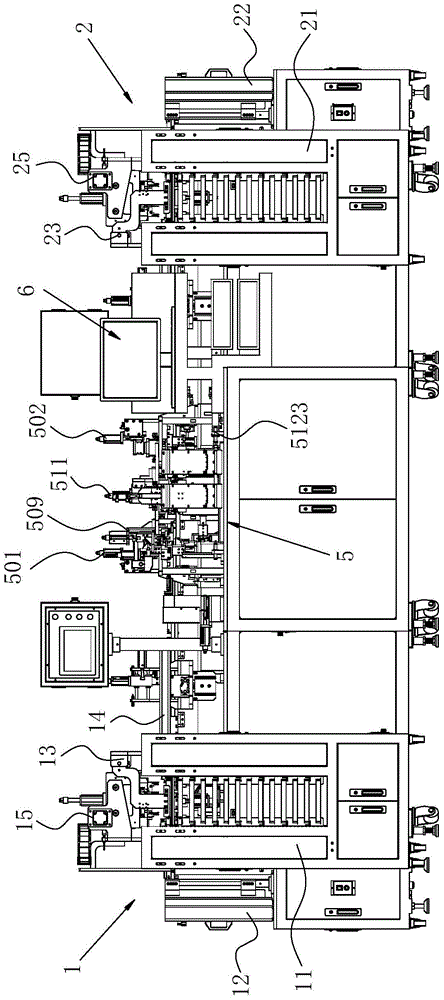

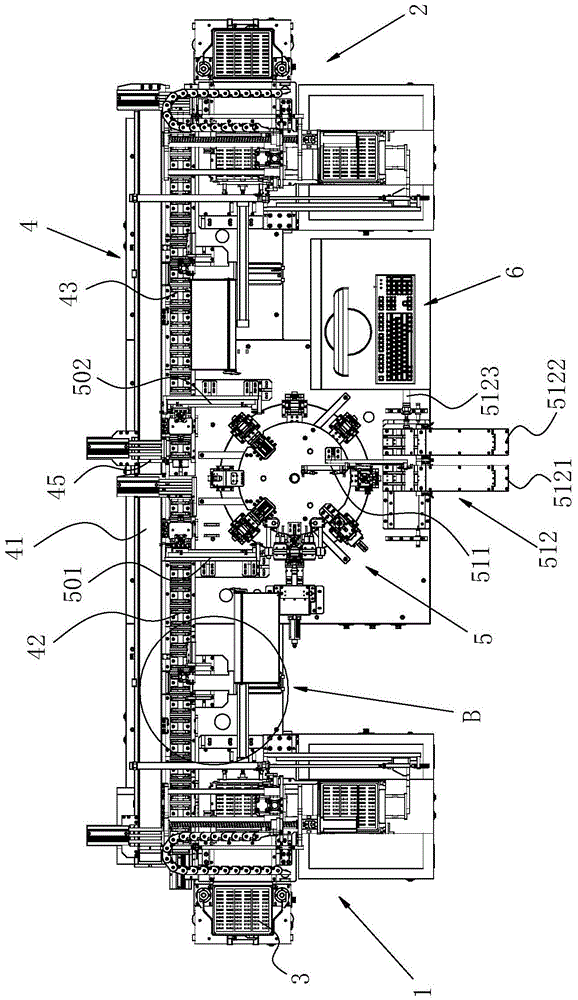

[0044] Such as Figure 1-7 As shown, in this embodiment, a code scanning test machine includes a code scanning test system 5 and a loading system 1 and a blanking system 2 respectively located on both sides of the code scanning testing system 5, and is used to connect the loading system 1. The conveyor line 4 connecting the code scanning test system 5 and the blanking system 2.

[0045] The code scanning test system 5 includes a rotating disk 503 that can rotate at a fixed angle, and an upper disk manipulator 501, a code scanning device 508, a performance testing device 509, a defective product recovery assembly 512, a lower disk, Disk manipulator 502 and empty detection device 510. The upper plate manipulator 501 is used to transfer the battery from the connecting transmission line 4 to the code ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com