Suspended ceiling system, secondary suspended ceiling section bar and splicing method

A technology of ceiling and profiles, which is applied in the field of secondary ceiling profiles, splicing, and ceiling systems, and can solve the problems of losing installation vertical walls and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

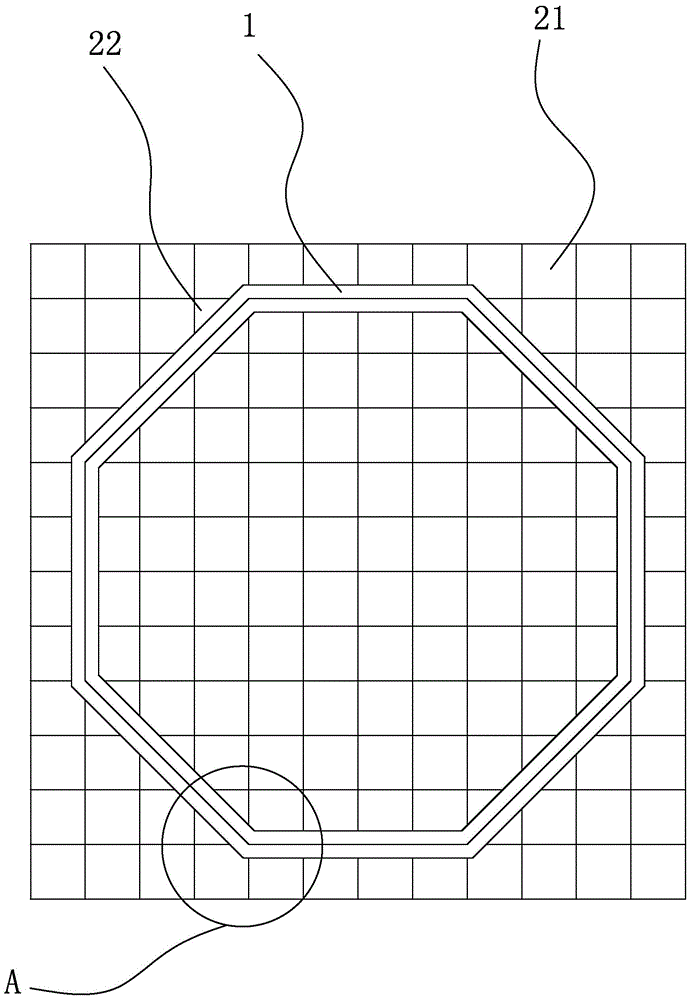

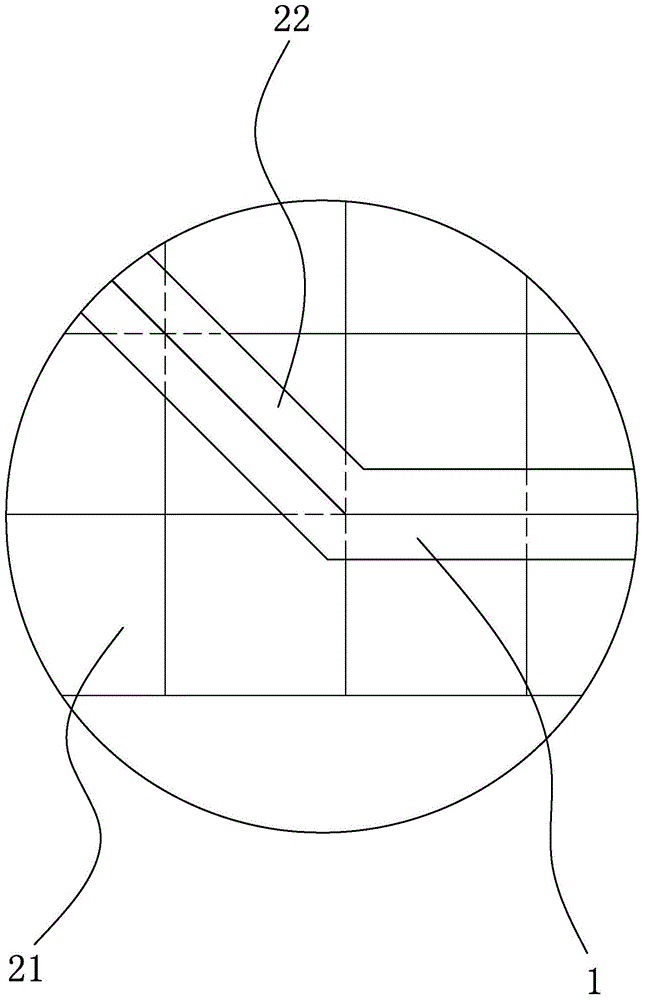

[0028] Such as figure 1 and 2 As shown, the ceiling system uses the secondary ceiling profile 1 as an outline to form an octagon. The octagon as shown has vertical or horizontal orthogonal sides, and a hypotenuse at a 45° angle to the orthogonal sides. The orthogonal side is connected to the integral metal ceiling 21 , and the hypotenuse is connected to the metal ceiling block 22 , and the metal ceiling block 22 is cut from the integral metal ceiling 21 along a diagonal line.

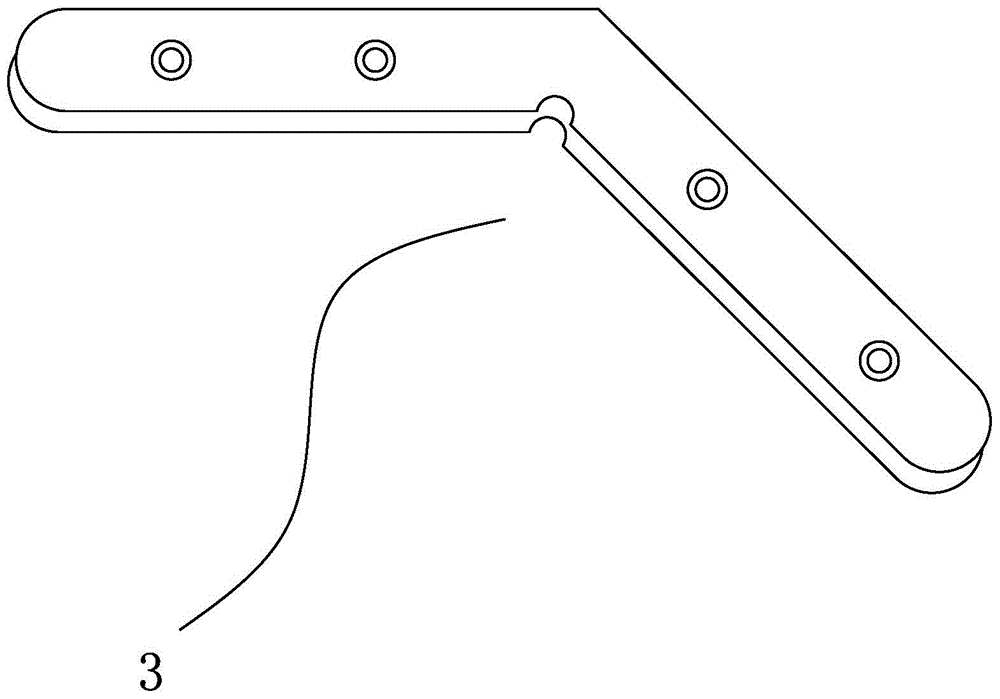

[0029] As a further preferred embodiment, the secondary ceiling profiles located at the corners of the octagonal outline are connected by a corner code of 135°. Such as image 3 and 4 Shown, described angle code comprises flat angle code 3 and vertical angle code 3 '. Since the traditional ceiling system only has right-angle graphics, there are only 90° corner angles correspondingly.

[0030] A splicing method for a ceiling system, comprising the following steps:

[0031] A. Measure the area of ...

Embodiment 2

[0041] Such as Figure 5 As shown, the upper side of the lower wall body 18 is provided with a corner code slot for inserting a vertical corner code.

Embodiment 3

[0043] Such as Figure 6 As shown, the upper side of the lower wall body 18 is provided with a corner code slot for inserting a vertical corner code, and the decorative surface 14 is connected to the upper wall body 11 and continues to extend a part to the left to enhance the artistic effect. The upper surface of the upper wall body 11 is also provided with a corner code slot for flushing into the vertical corner code.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com