A multi-axis loaded axle assembly durability test bench

A durability test and axle loading technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as the inability to realistically simulate the stress of the axle assembly, and facilitate data analysis and improve simulation. The effect of correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

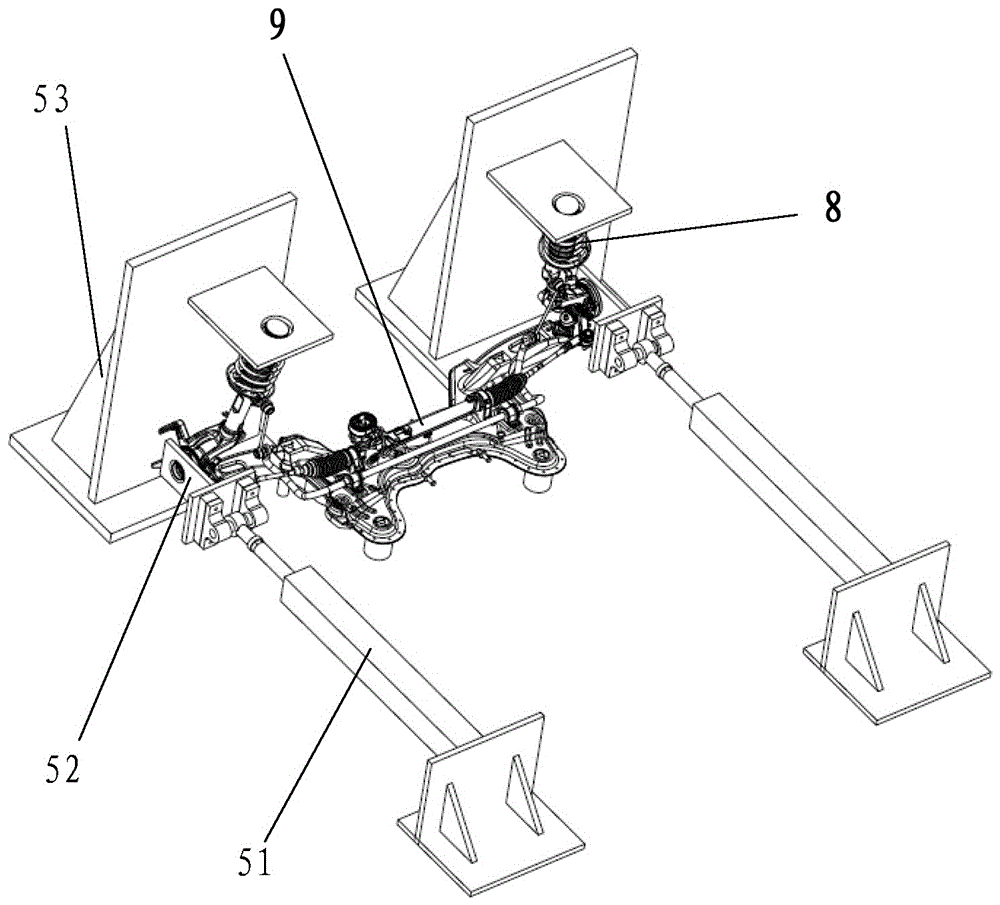

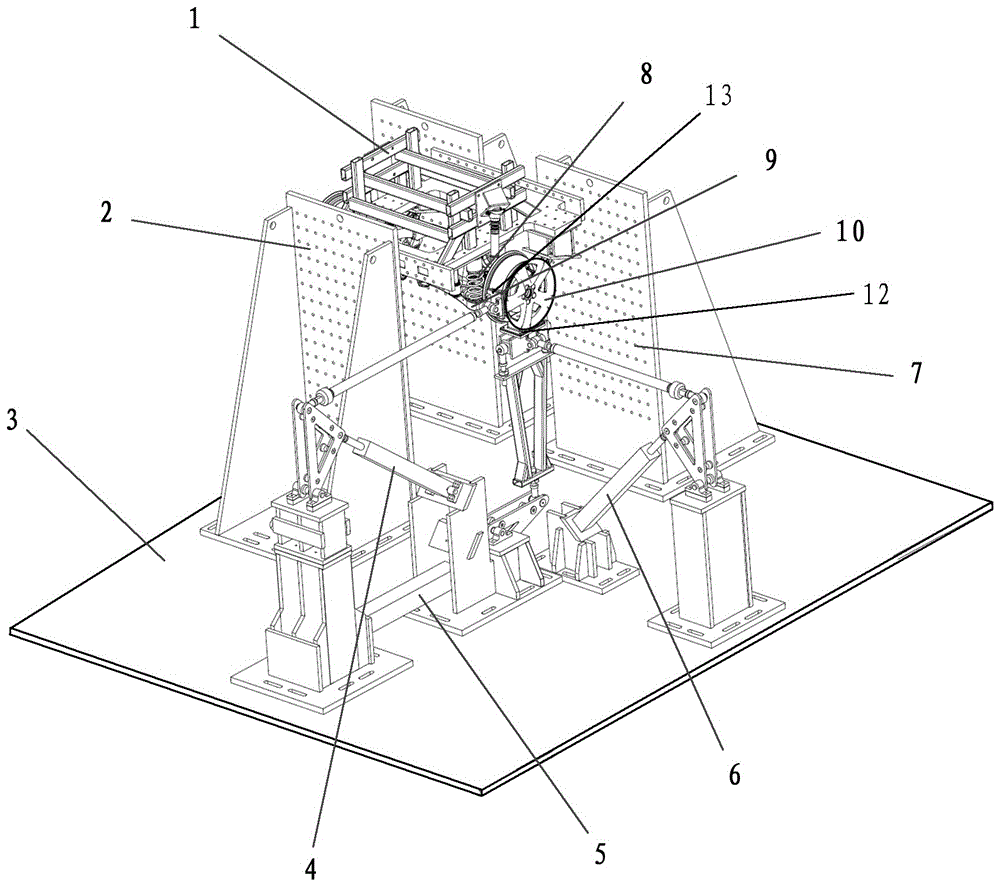

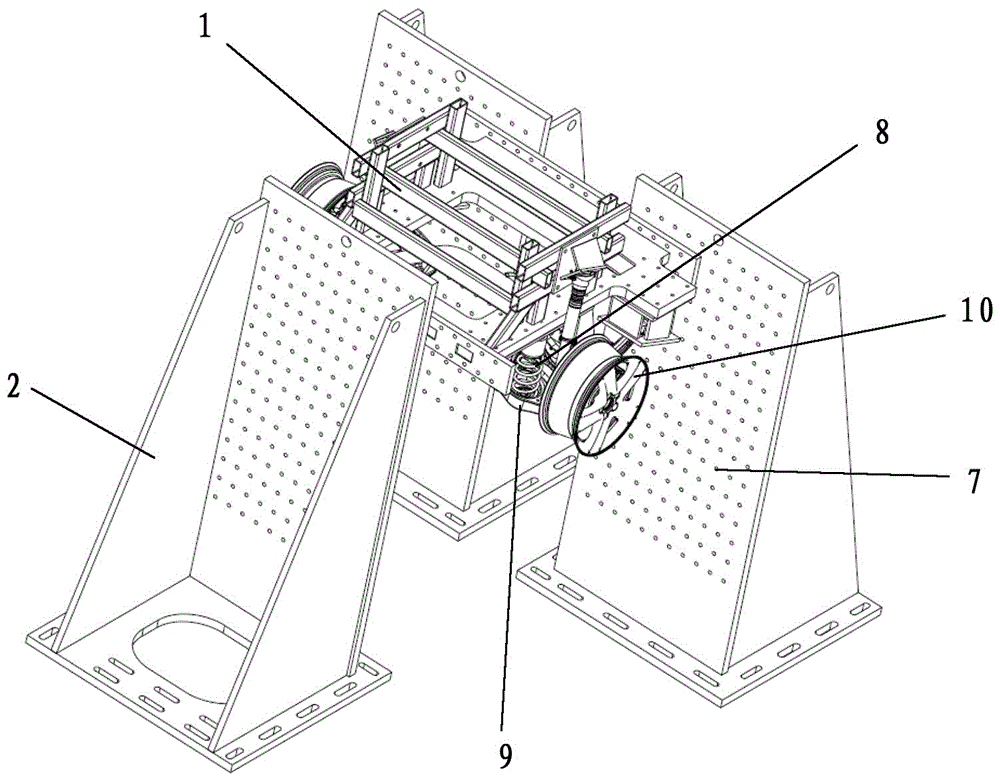

[0022] according to Figure 2-7 The specific structure of the present invention will be described in detail. Such as figure 2 and 3 As shown, a multi-axis loading axle assembly durability test bench, the axle assembly support 2 is fixed on the test bench base 3, and the axle assembly mounting frame 1 is fixed on the upper part of the axle assembly support , the loading device fixed on the base of the test bench includes a longitudinal loading device 4 , a vertical loading device 5 and a lateral loading device 6 . There are three axle assembly supports 2, which are arranged opposite to each other. The axle assembly supports have a certain height, and a plurality of mounting holes 7 are arranged on the side wall for fixing the axle assembly mounting frame 1 on the axle assembly support. On the mounting holes 7 on the opposite sides of the three axle assembly supports 2. During the test work, the automobile axle assembly 9 is fixed on the axle assembly installation frame 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com