Coil component and manufacturing method thereof

A technology of coil assembly and manufacturing method, applied in the direction of transformer/inductor coil/winding/connection, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as reduced productivity, increased manufacturing cost, and increased size of SMPS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Exemplary embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings.

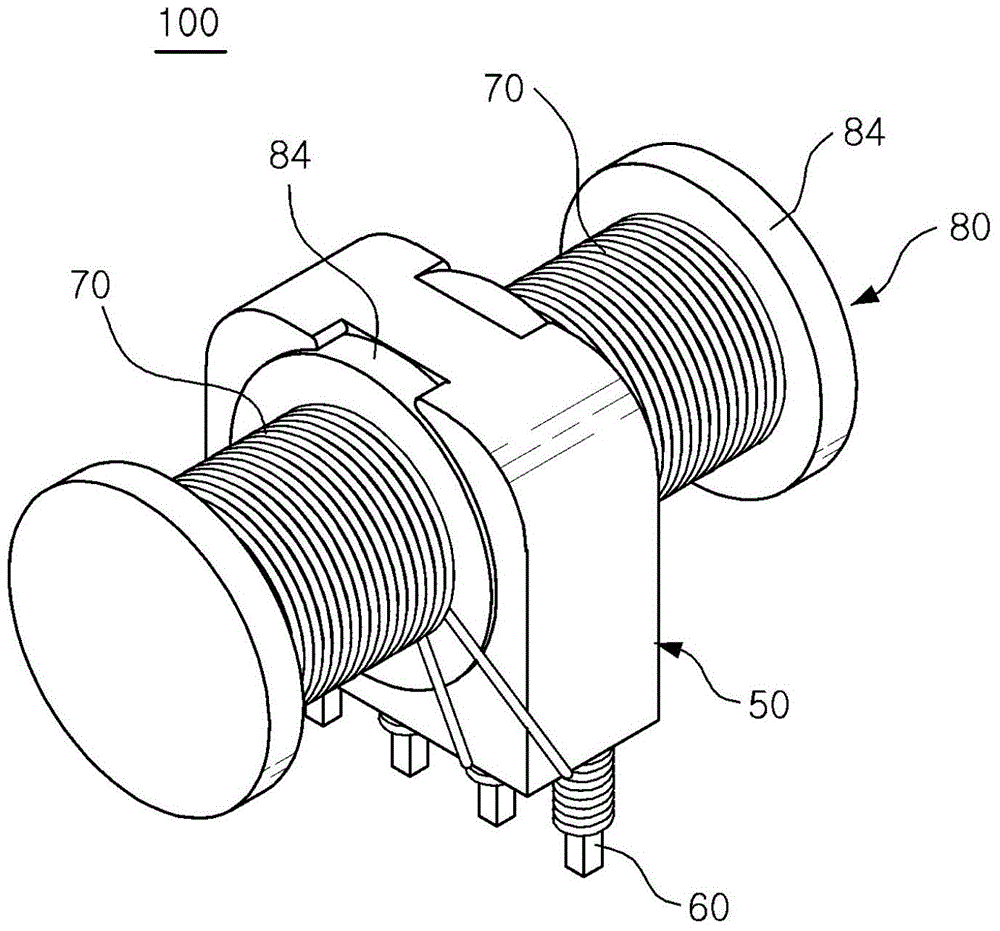

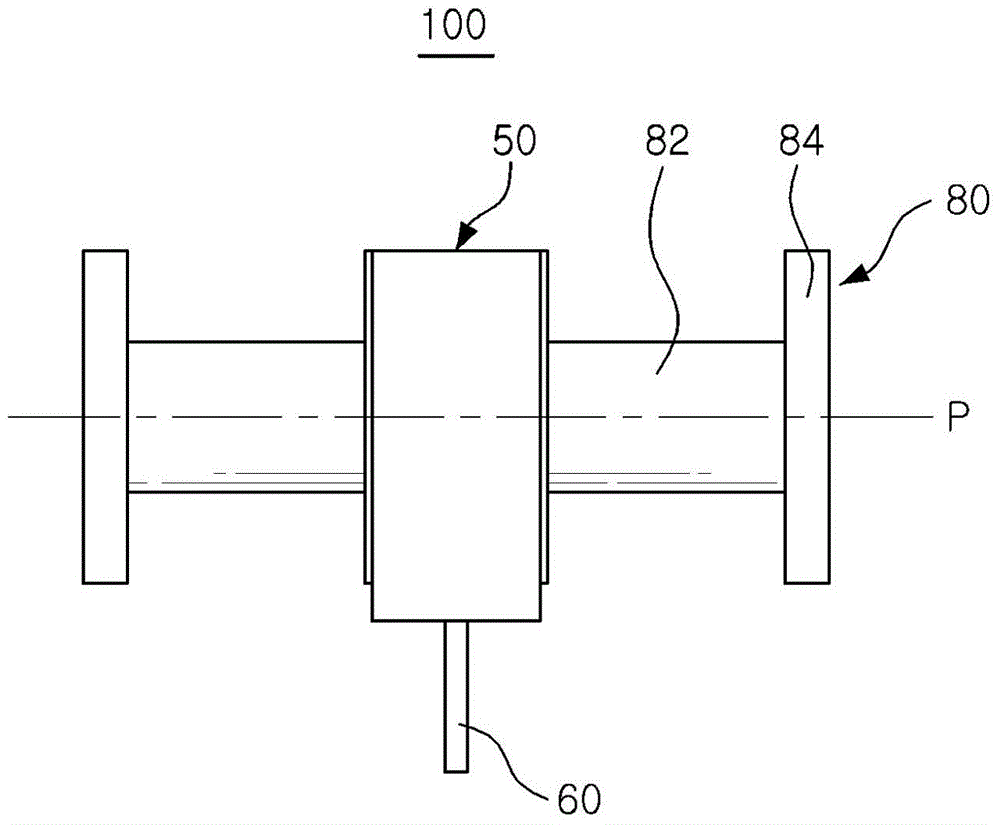

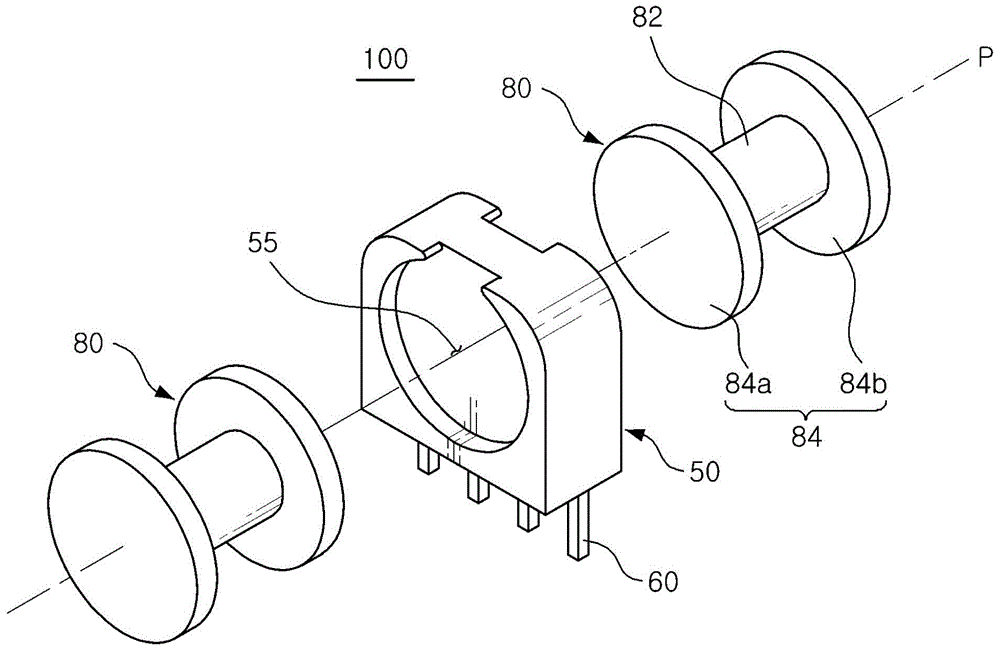

[0040] figure 1 is a perspective view schematically showing a coil assembly according to an exemplary embodiment of the present disclosure, figure 2 yes figure 1 A side view of the coil assembly with the coil removed is shown in, image 3 yes figure 1 An exploded perspective view of the coil assembly with the coil removed is shown in .

[0041] refer to Figure 1 to Figure 3 , the coil assembly 100 according to an exemplary embodiment of the present disclosure may be a coil assembly used in a direct current (DC) / DC converter provided in a power supply, and may include a drum core 80 , a coil 70 and a substrate 50 .

[0042] The drum core 80 (a part of the drum core 80 on which the coil 70 is wound, which will be described below) may include a cylindrical main body portion 82 and flange portions 84 extending from both ends of the main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com