Liftable shifting-out equipment

A removal and equipment technology, applied in the field of lifting and removal equipment, can solve problems such as prone to rollover and difficult product transportation, and achieve the effects of avoiding operation methods, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

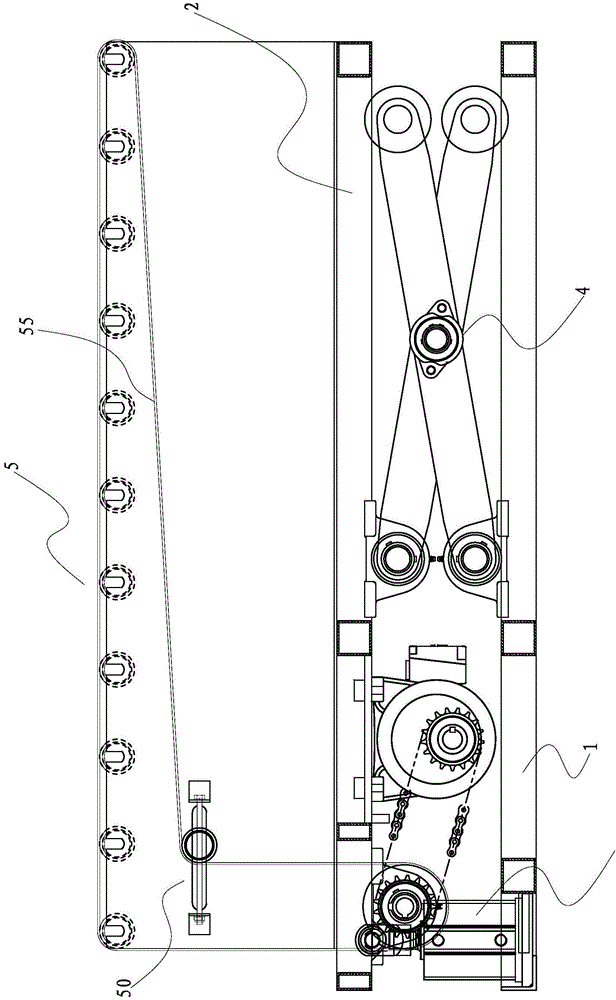

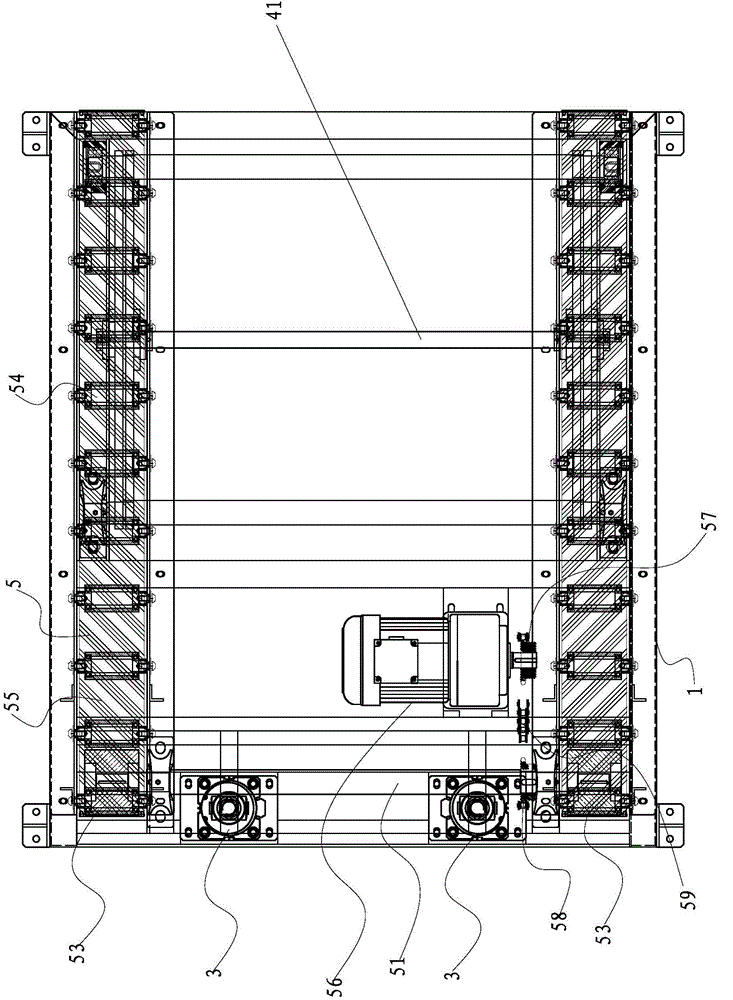

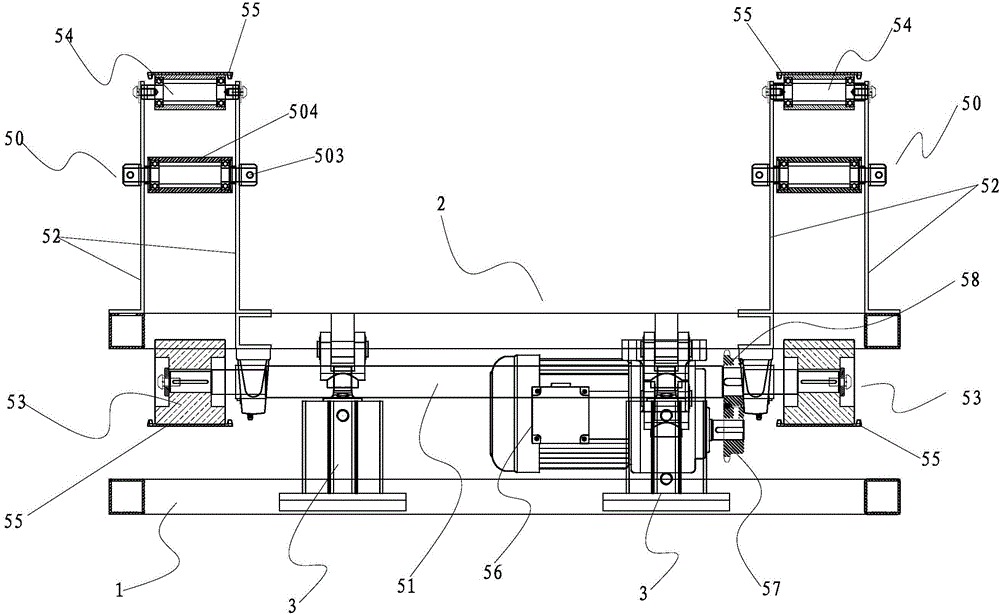

[0031] A liftable removal device of the present invention comprises a base 1 and a lifting frame 2 arranged above the base 1, the lifting frame 2 is provided with a moving out track 5 for docking two conveying tracks of different heights, the base 1 and A lifting drive device 3 for driving the lifting frame 2 to rise and fall relative to the base 1 and a support mechanism 4 for assisting in supporting the lifting frame 2 are arranged between the lifting frames 2 . When the product is transported from one conveying track to the moving out track 5, the lifting drive device 3 is activated to move the moving out track 5 up or down, so that the height of the moving out track 5 is consistent with the height of the other docked conveying track, so as to achieve The products are changed lanes and lines on two conveying tracks with different heights to ensure continuous and automatic production, avoiding the manual operation mode of changing lanes, and improving production efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com