Material returning system applicable in multi-station automatic stretching and punching device

A multi-station, punching machine technology, applied in the direction of stripping devices, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting production efficiency, inaccurate material return, and many molds, so as to ensure continuous automatic production, accurate material return, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

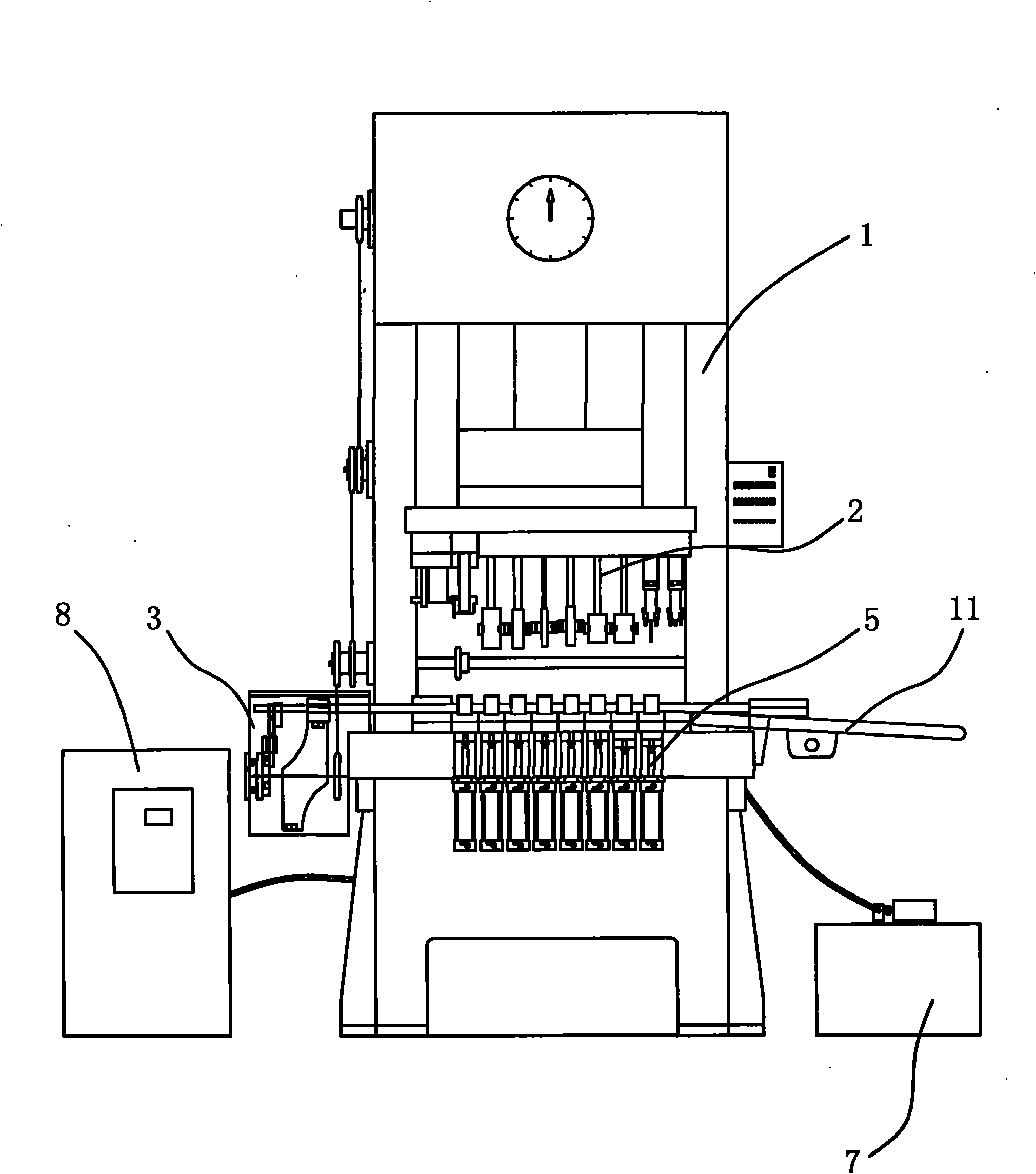

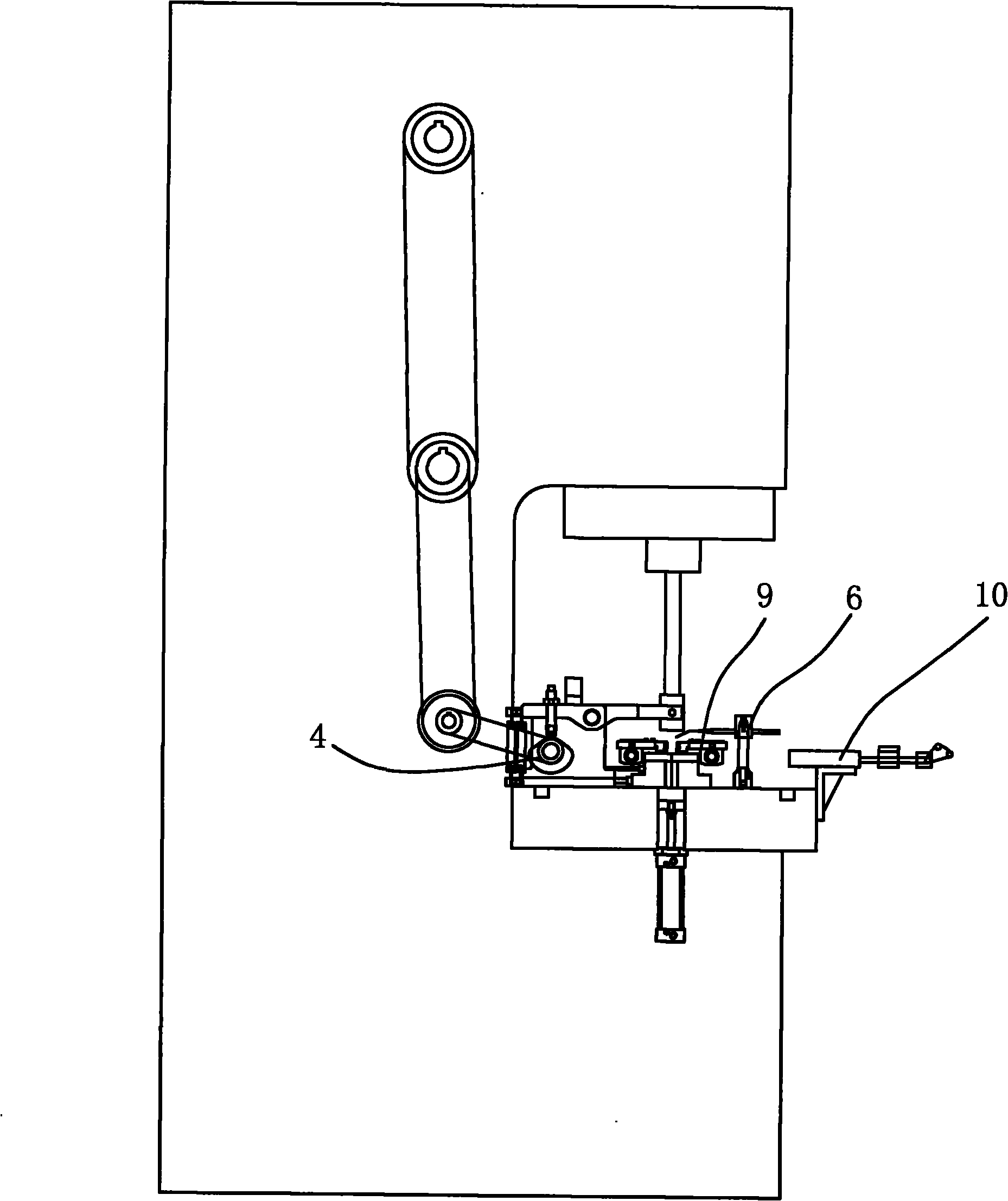

[0032] see Figure 1 to Figure 22 As shown, a kind of processing method of multi-station automatic stretching provided by the present invention is illustrated below in conjunction with the first embodiment, and its specific processing process is:

[0033] First, the coil material is sent to the first station of the mold through the pneumatic feeder 10 for blanking or blanking stretching, and then the cylindrical cam 45 in the transmission system 3 drives the manipulator 9 to move left and right; at the same time, the manipulator 9 Driven by another disc cam 58, it moves forward and backward, and the manipulator 9 clamps the round material or semi-finished product and is driven by the transmission system 3 to feed forward and backward;

[0034] The second step, multi-station stamping and forming: the manipulator 9 transports the round material or semi-finished product to the second station of the mold, and the stretching punch pulls the round material or semi-finished product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com