High-lift forklift, calibration method for returning storage container and storage medium

A container and forklift technology, applied in the direction of lifting devices, etc., can solve the problems of failure to return inventory containers, falling of high-level goods, damaged inventory containers, etc., and achieve the effect of improving return efficiency and accurate return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

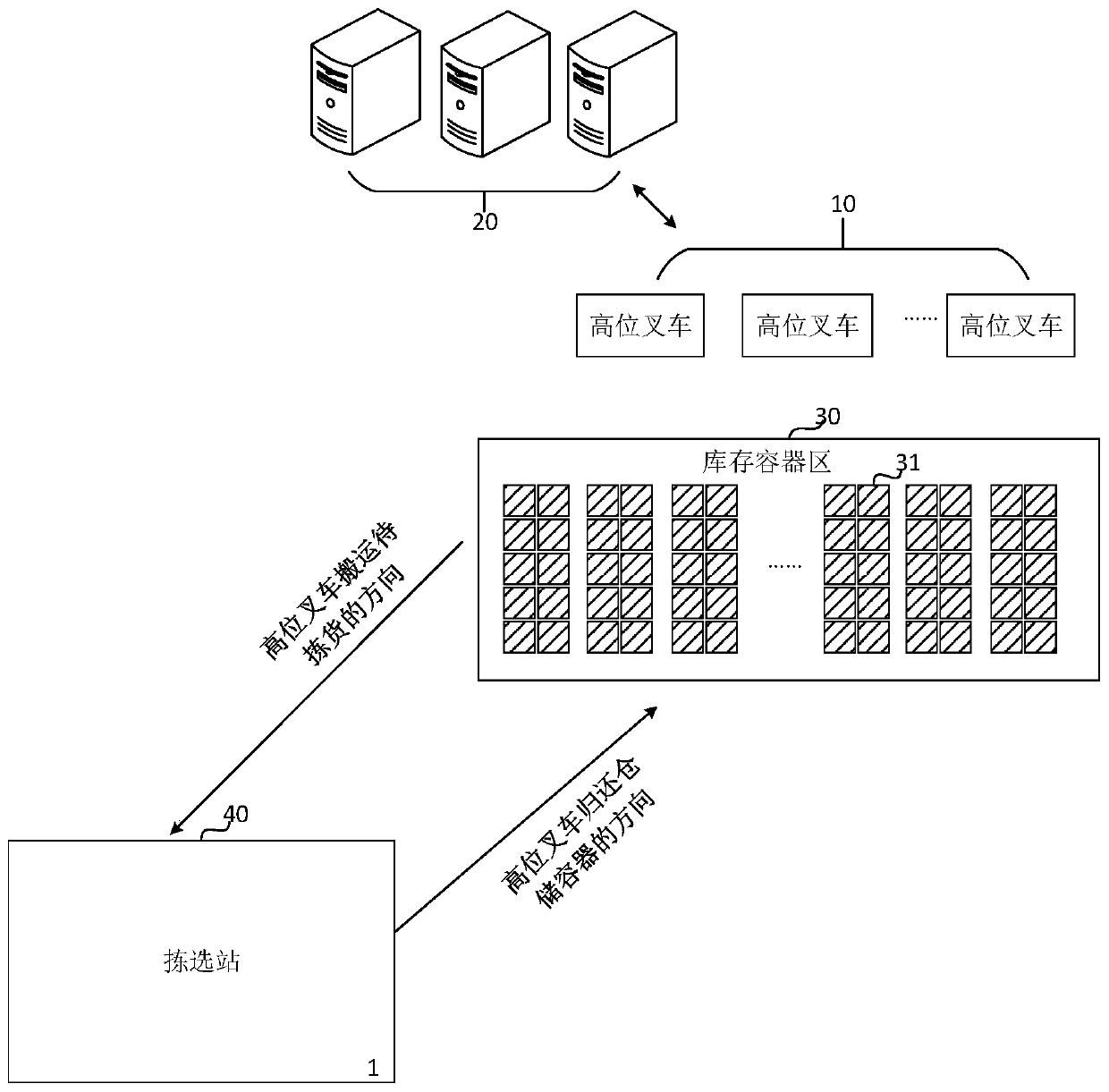

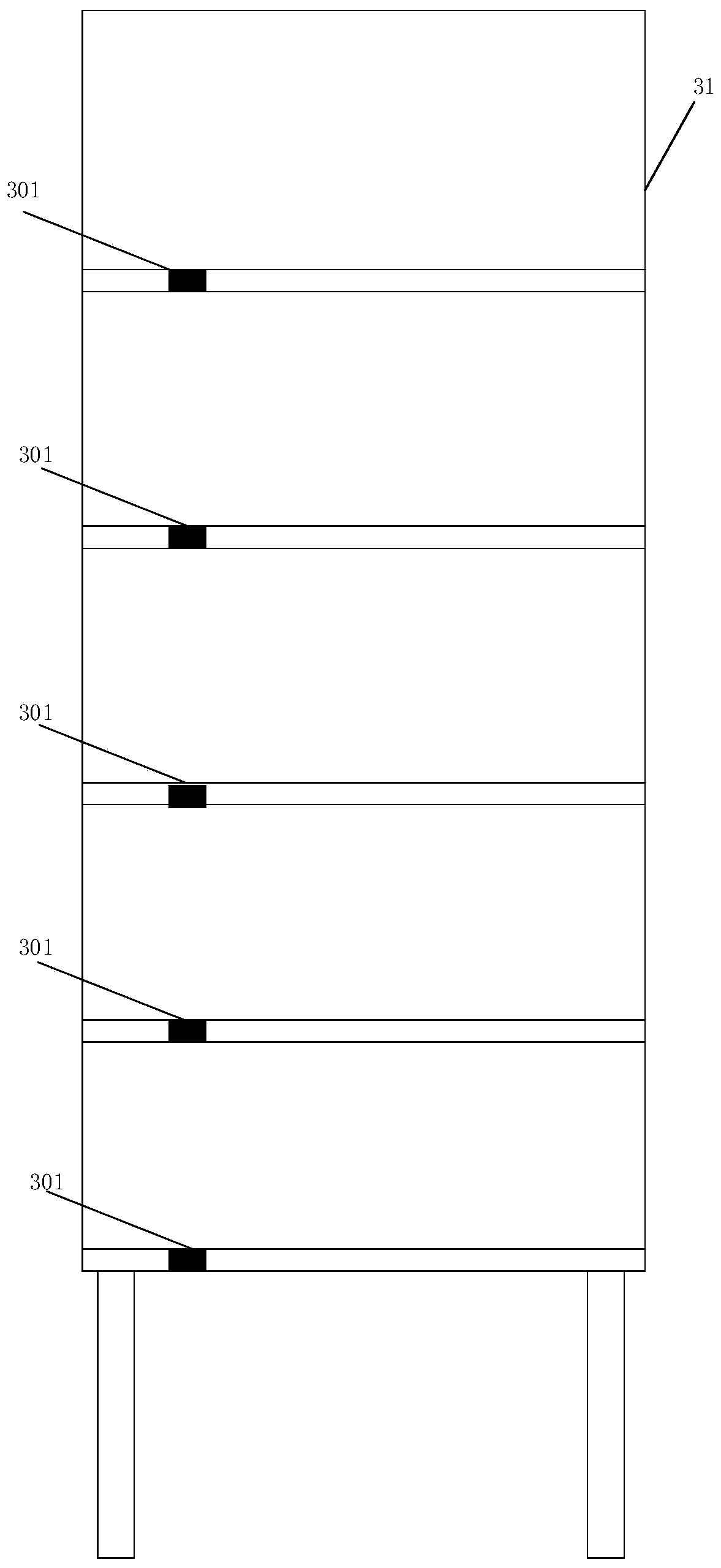

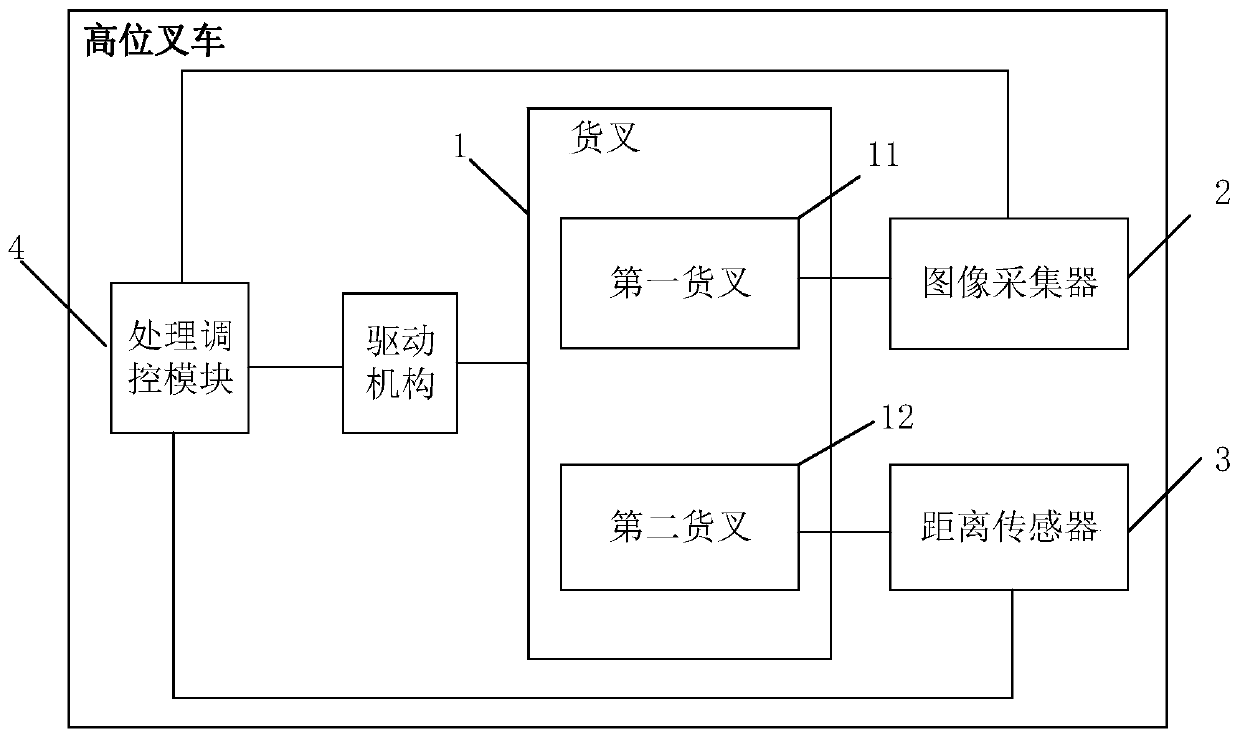

[0033] image 3 It is a schematic structural diagram of a high-position forklift provided in Embodiment 1 of the present invention, including a fork 1, an image collector 2, a distance sensor 3 and a processing module 4, wherein the processing control module 4 is connected with the fork 1, the image collector 2, The distance sensor 3 is electrically connected; further, the processing control module 4 is connected with the fork 1 through a driving mechanism, and controls the movement of the fork 1 through the driving mechanism, and the driving mechanism includes a driving motor, gears and other components. It should be noted here that the high-position forklift in other embodiments of the present invention (such as Figure 4 and Figure 5a ) The drive mechanism in the present embodiment has the same composition and function as the drive mechanism in this embodiment.

[0034] The pallet fork 1 includes a first pallet fork 11 and a second pallet fork 12 for carrying storage con...

Embodiment 2

[0043] Figure 4 It is a schematic structural diagram of a high-position forklift provided in this implementation. This embodiment is optimized on the basis of the above-mentioned embodiments. The processing control module 4 includes:

[0044] The target position adjustment unit is used to control the fork to move to the target position by moving left and right or up and down according to the position of the collected positioning mark in the image taken by the image collector, wherein, at the target position, the positioning mark corresponds to The projected image of is located at a preset standard position within the image captured by the image grabber.

[0045] Wherein, the preset standard position is exemplarily the center position of the image captured by the image collector. Due to the flatness of the ground or the control accuracy of the high-level forklift itself, when the fork lifts the storage container to the same height as the target layer of the target storage con...

Embodiment 3

[0051] Figure 5a It is a schematic structural diagram of a high-position forklift provided in this implementation. This embodiment is optimized on the basis of the above-mentioned embodiments. The processing control module 4 includes:

[0052] A judging unit, configured to judge the collected positioning mark according to the position of the collected positioning mark in the image captured by the image collector before the vertical moving unit moves the fork vertically upward from the target position by a preset distance Whether the angle deviation in the horizontal direction is greater than the preset angle threshold.

[0053] Due to the influence of the flatness of the warehouse floor, the fork will have a certain inclination, so it is necessary to determine whether the inclination of the current fork will affect the return of the storage container. Specifically, it may be determined by judging whether the angle deviation of the collected positioning marks in the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com