Method for simulating exploitation of worked-out section and device for achieving method

A technology of gobs and hollow pipes, applied in the field of a method and the device for realizing the method, which can solve problems such as difficulty in pulling out the iron box, affecting the ecological environment, and poor experimental results, and achieves simple implementation and good experimental results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

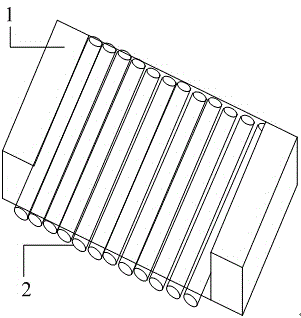

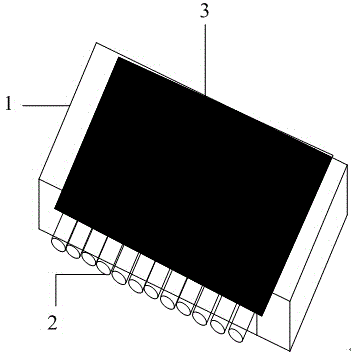

[0021] This embodiment provides a method for simulating goaf mining. The design principle of the method for simulating gob mining is: fill the pit with a rubber hose filled with a thin, flowable filling material, and overlying the rock formation, and then release the rubber hose. The filling material can be flowed to simulate the mining of the goaf.

[0022] In this embodiment, the hardware for simulating goaf mining is as follows: a main body with a pit, which provides installation locations for rubber hoses; several rubber hoses, each of which is filled with fine flowable filling materials, the number and radius of rubber hoses, etc. The specifications are determined according to the size of the pit, and the size of the pit is determined according to the size of the simulated goaf. The two ends of the rubber hose are knotted; the steel wire or iron wire is used to wrap the knot at both ends of the rubber hose and to fasten the two ends Sealing; hollow pipe, used to insert fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com