Improvements to selective tea plucking

A selective, vegetative technology, applied in the fields of picking machines, agricultural machinery and implements, agriculture, etc., can solve the problems of tea plants maintaining leaves and stem material damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

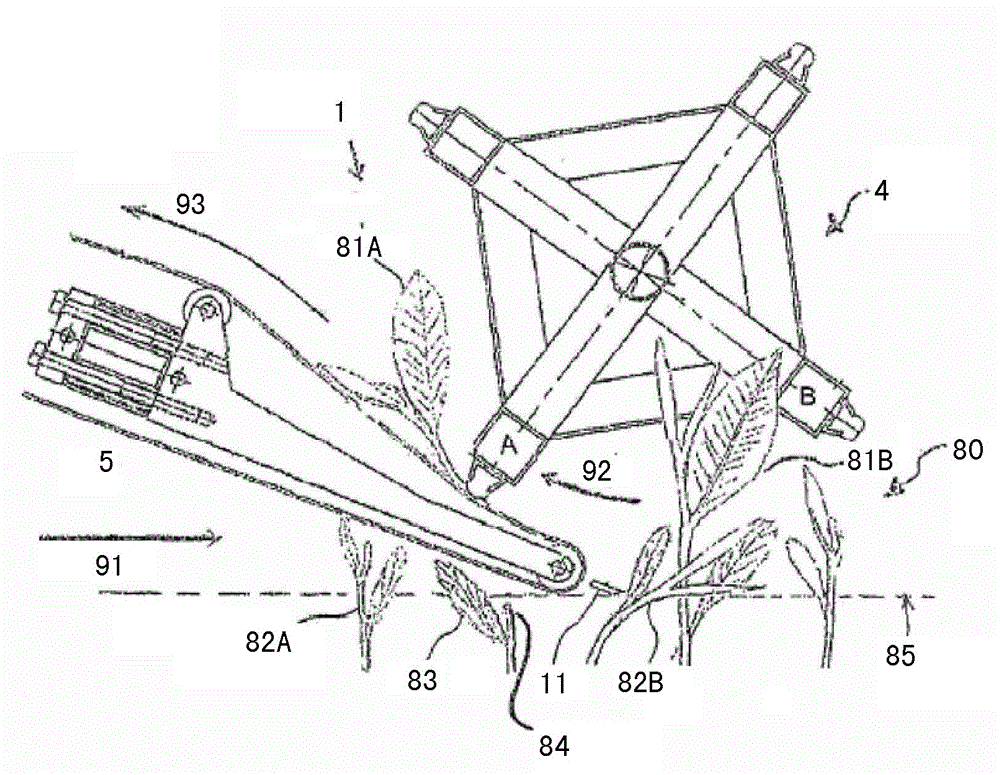

[0042] As mentioned above, it is desirable to provide a tea harvester that can selectively harvest the largest area of tea shoots without damaging immature tea shoots and preserve the leaves.

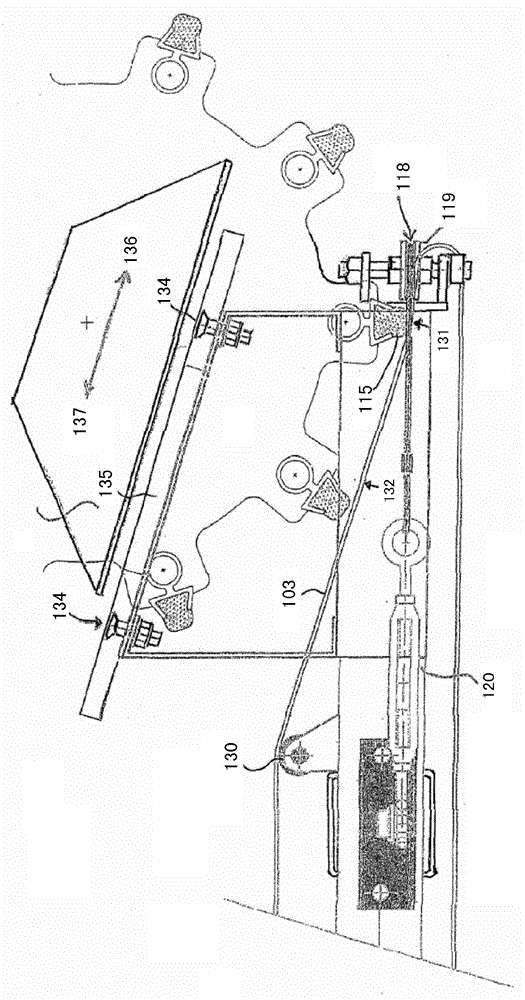

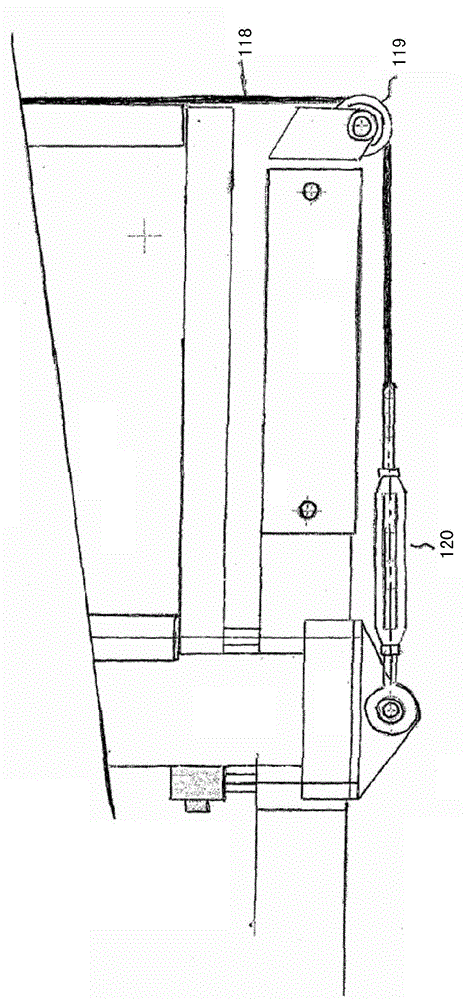

[0043] device

[0044] refer to Figure 1 to Figure 4 as well as Figure 8 The tea harvester 1 comprises a conveyor belt assembly 2 , a second plant engaging member being a rotor assembly 4 and a stem engaging member being a crusher rod assembly 3 . The conveyor belt assembly 2 comprises a conveyor belt 5 made of elastic material constituting the first plant engaging member, a front belt support roller 6 at the leading edge of the conveyor belt assembly 2, a rear belt support roller 7, a conveyor cross tube support Part 8, supporting part 9 and fixing bolt 10. The conveyor belt 5 is mounted on a front belt support drum 6 and a rear belt support drum 7 , which are supported by support members 9 linked to conveyor cross tube supports 8 . The support part 9 is attached to the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com