Glass breaker power adjusting device

A technology of adjusting device and glass breaker, which is applied in the direction of striking tools, portable impact tools, manufacturing tools, etc., can solve the problems of inconvenient adjustment, achieve the effects of simple structure, saving selection time, and improving glass breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

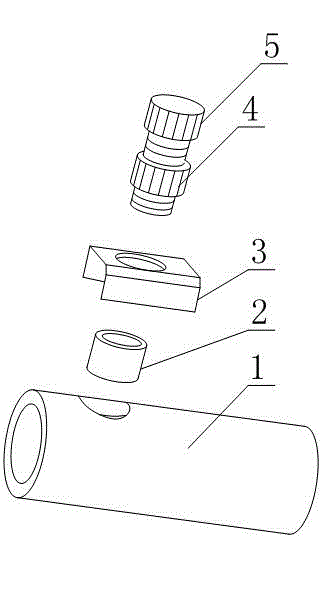

[0028] Such as figure 1 As shown, the glass breaker power adjustment device includes a piston cylinder 1, and the piston cylinder 1 is provided with a through hole communicating its inner cavity with the outside world, and also includes a bolt fixing block 3, which is fixedly connected to the piston On the barrel 1 , the bolt fixing block 3 is also provided with an adjusting bolt 5 threadedly connected with the bolt fixing block 3 , and the axial direction of the adjusting bolt 5 is collinear with the axial direction of the through hole.

[0029] Specifically, the set piston cylinder 1 is the energy generating chamber of the explosive glass breaker, that is, the explosive bomb used explodes in the piston cylinder 1 to generate rapidly expanding gas, and the through hole arranged on the piston cylinder 1 is used for the discharge part Gas; and by rotating the adjusting bolt 5 relative to the bolt fixing block 3, the distance between the adjusting bolt 5 and the piston cylinder ...

Embodiment 2

[0032] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown, the bolt fixing block 3 is in the shape of a groove with one end closed.

[0033] Also includes a cylindrical internal thread sleeve 2, the center of the internal thread sleeve 2 is provided with a central through hole, and the inner wall surface of the central through hole is provided with internal threads, and one end of the internal thread sleeve 2 is fixedly connected to the bolt fixing block 3, and the internal thread sleeve 2 is located between the piston cylinder 1 and the bolt fixing block 3, and the distance between the other end of the internal thread sleeve 2 and the outer wall of the piston cylinder 1 is within the range of 1 mm to 3 mm.

[0034] This arrangement has a simple structure and is easy to process and manufacture. Specifically, after the connection between the bolt fixing block 3 and the piston cylinder 1 is completed, when the explosive glass breaker is in us...

Embodiment 3

[0036] The present embodiment is further limited on the basis of embodiment 1, as figure 1 As shown, it also includes a locking nut 4 , which is threadedly connected with the adjusting bolt 5 , and the locking nut 4 is located between the bolt fixing block 3 and the outer end of the adjusting bolt 5 .

[0037] The threads on the bolt fixing block 3, the locking nut 4 and the adjusting bolt 5 are all fine threads.

[0038] The set lock nut 4 is used to fix the position of the adjustment bolt 5 relative to the bolt fixing block 3 through the lock nut 4 after the adjustment bolt 1 is adjusted to a reasonable position, so as to ensure the stability of the performance of the present invention during use.

[0039] The fine-pitch screw thread has a smaller tooth pitch, and this setting makes the present invention have better power adjustment performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com